Refining the circular economy for battery materials.

As the e-mobility transition accelerates, demand for critical minerals is growing exponentially. Companies on the cutting edge, such as Tesla, are already experiencing shortages. However, to extract ever more minerals by mining and dispose of the waste in landfills, would be to continue the practices that got the world into its current environmental mess. Furthermore, expanding mining operations here in the US is often extremely difficult, due to permitting regulations and logistical challenges.

Fortunately, large amounts of the critical minerals needed for the energy transition are already in circulation today. Increasing the efficiency of recycling offers a way to “close the loop,” creating a circular supply chain that can provide the needed raw materials for batteries and other components and minimizing the need to expand the world’s mining operations.

Nth Cycle works with battery recyclers and miners to recover production-grade critical minerals from separated electronic waste and low-grade mine tailings. The company says its electroextraction technology—an alternative to the more traditional methods hydrometallurgy and pyrometallurgy—enables customizable, mobile, clean and consistent recovery of critical minerals.

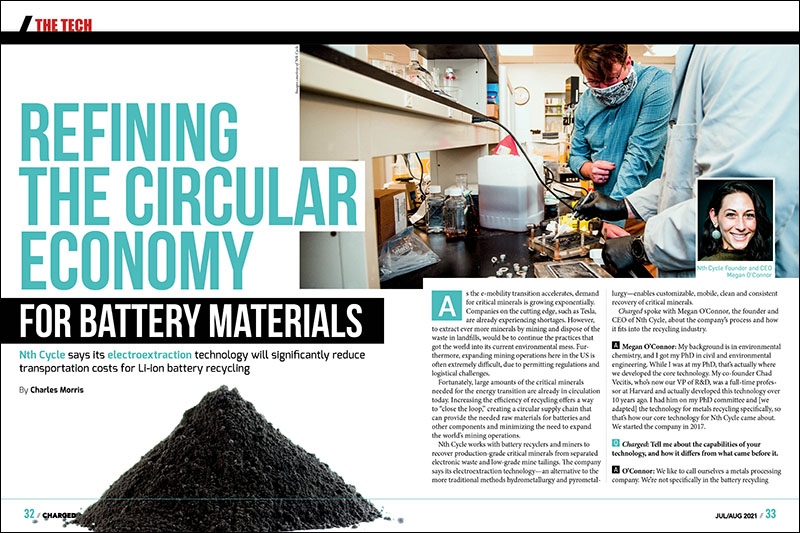

Charged spoke with Megan O’Connor, the founder and CEO of Nth Cycle, about the company’s process and how it fits into the recycling industry.

Megan O’Connor: My background is in environmental chemistry, and I got my PhD in civil and environmental engineering. While I was at my PhD, that’s actually where we developed the core technology. My co-founder Chad Vecitis, who’s now our VP of R&D, was a full-time professor at Harvard and actually developed this technology over 10 years ago. I had him on my PhD committee and [we adapted] the technology for metals recycling specifically, so that’s how our core technology for Nth Cycle came about. We started the company in 2017.

We actually use a combination of electricity with water filtration. That’s really where our core IP is—combining these two technologies in a process called electroextraction or electrowinning.

Charged: Tell me about the capabilities of your technology, and how it differs from what came before it.

O’Connor: We like to call ourselves a metals processing company. We’re not specifically in the battery recycling space, or the mining space—we cover all feedstocks across the supply chain. Our true mission is to enable a very low-impact, streamlined supply of all critical minerals for the energy transition. We work with battery recyclers, mining companies, refineries, and everything in between, looking at all feedstocks to solve this critical issue of supply chain management. Compared to some of the folks you see in the battery recycling space or the mining space, who use traditional hydrometallurgy and pyrometallurgy, we are a replacement or enhancement to those, with a technology called electroextraction.

Our electroextraction technology is very modular. It has what I call the three Cs: it’s clean, consistent and customizable. It has a wide variety of locations that we can deploy in, and that really helps us take advantage of the different feedstocks that North America has to offer, and tap a lot of these valuable resources that we haven’t been able to go after in the past. We can also reduce greenhouse gas emissions by over 75% compared to traditional hydro and pyro, and create a very consistent output. It’s really critical, especially in the battery recycling space, where you get a wide range of feedstocks coming from different cathode chemistries, to be able to produce a very consistent output.

Charged: How exactly does your electroextraction technology complement traditional hydrometallurgy and pyrometallurgy processes?

O’Connor: Pyrometallurgy you can think of as a large furnace—really high-temperature, high-pressure furnaces that take the waste, burn it into ash, and pull out the metals as slag. Hydrometallurgy is where they take the waste and dissolve it in acid, and then follow that up with solvent extraction. They use a number of different solvents to pull out these metals, one by one, to produce the final battery-grade material.

How our technology differs is, we don’t use any high temperatures or high pressures or solvents to pull these metals out. We actually use a combination of electricity with water filtration. That’s really where our core IP is—combining these two technologies in a process called electroextraction or electrowinning, which is used very frequently in the mining and refining space. You can think about pushing electrical current across a very large filter, and that electrical current helps us capture the metals selectively. That’s really how our technology differs from the hydro and pyro, and helps us get to those very little operating costs, because our only input is a very low level of electricity that can come from a hundred percent renewable, versus the high chemical and energy use of the other two.

Charged: How does using electricity and filters capture the specific materials you want?

O’Connor: We can actually tune the voltages that we apply to our system, so we’re playing with the reduction potentials [the tendency of a chemical to acquire electrons from or lose electrons to an electrode] of the metals themselves. Each metal has a different attraction to different voltages that you apply, so depending on how we apply those, we can actually select for the different metals as we apply a different voltage to each filter that we have in our system.

By combining the two processes, we’re turning it from a batch process to a flow-through, continuous process. You can imagine a basic water filter, like you’d use for well water or a pool, and we’ve simply figured out a way to electrify it safely. So, we push the fluid through, like we’re filtering water, but then we apply that voltage across [the filter], the metals precipitate out selectively and fall to the bottom, and we can collect them from there.

Charged: What kind of materials are the filters made from?

O’Connor: That’s part of the innovation—using a carbon-based filter in our system, instead of using traditional filters you’d see in filter presses. That’s how we’re able to get the very low operating costs, as well as significantly reduced greenhouse gas emissions. Using a carbon filter is our key enabler in this entire process of using electricity to produce these metals, so the reduction in the volume of chemicals that we use by using this filter instead is how we reduce the greenhouse gas emissions.

We did not design it specifically for this. These are filters that are used in a wide variety of other applications, and we adapted it for this application ourselves. We do not make them internally.

Charged: In the other applications they’re used in, are they used with this kind of electricity across the filters, or is that something new?

O’Connor: That is something new that we do. They are used in a couple other different applications in the fuel cell battery space, but we specifically use them for this water filtration application.

Charged: In a typical lithium-ion battery recycling process, would this be an added step that would help what’s currently used, or would it replace things?

O’Connor: We can do both, and it depends on the battery recycler. We sort of see them in two buckets. We have the legacy recyclers, who have been around for a while, recycling other types of batteries, and have moved on to lithium-ion. They’re really good at logistics. They collect these materials, and then they shred them down into what’s called black mass. This black mass is a mixture of the cathode and the anode. It’s a lot of graphite, and then the metals of interest like cobalt, nickel and manganese. Right now, these folks are losing money on this product, because it’s not worth very much. What we’re doing there is actually adding our process on, to upgrade that product to a much more valuable battery metal product for them to sell.

Then you have folks who are more vertically integrated in the space, who are going all the way from collection to producing the battery sulfate materials, which are going directly back into manufacturing, and there we can actually slot in right in the middle. So that would be, not necessarily a replacement, but an enhancement to increase the quality of the product in the middle of their process to make their other unit processes much more efficient. They have a hydrometallurgical step at the end to produce a sulfate, and we can significantly reduce the emissions and the energy use required for that final step by coming in in the middle and helping to upgrade that mid-grade black mass.

It is a significant cost to them to transport all of that mass when only 20% of it is valuable, so the real value we bring is a very effective, clean way to upgrade this material

The big value that we bring, to both parties actually, is a significant reduction in transportation costs. Both parties have to ship this black mass to a different location, whether they’re selling the black mass or transporting it to another site internally to process. It is a significant cost to them to transport all of that mass when only 20% of it is valuable, so the real value we bring is a very effective, clean way to upgrade this material—not only to reduce the transportation costs, but also, for the legacy recyclers, to drastically increase the price of that final product. So, it’s going from a waste product to a suite of valuable products for them to sell. And for the vertically-integrated folks, a much higher-quality product that goes into their final refining stage.

Charged: So, at the locations where the batteries are broken down to black mass, you will install your system, separate out the valuable things, and then ship those.

O’Connor: That’s right. Our core value to them will be a much more efficient, cleaner way to process that black mass into these separated valuable products.

Charged: What materials can you extract with this technology?

O’Connor: We recover cobalt, nickel, manganese, graphite and copper.

Charged: Do those come out as a usable product, or do they have to be processed?

O’Connor: Those come out as usable products, and they’re metal hydroxide powders.

Charged: What phase is the company in? Are you in production? Do you have these systems in any active lines?

O’Connor: We’re actually ramping up to deploy our first two units in the field in early 2022. Our first couple of partners are in the recycling space. They’re folks that are in the logistics game, who have collected this material, and we’re going in to upgrade it to a more valuable suite of metal products.

Charged: Other than batteries, are there some other processes that you’ll use this technology on?

O’Connor: Yes. We are also looking at projects in the mining and refining space, working with mining companies who are looking at new ore bodies, especially in the United States and Canada. There’s a lot of cobalt and nickel assets here that have not been able to be tapped, because the technologies are either too expensive or can’t fit within the permitting regulations in each state. And so we’re looking at those to go onsite and actually upgrade the raw ore, to create more supply of these critical materials here in the States, so we don’t have to rely as heavily on overseas supplies.

Charged: Will you be producing the systems, building the equipment and everything?

O’Connor: No. We have our internal system that we scaled with, but at that scale, we will do all contract manufacturing. Our model is to own and operate these filters on-site with our customers, but not actually sell the units themselves.

Charged: What are the next steps for the company? Are you out there actively seeking partners, or is there still technology development to do?

O’Connor: We are actively seeking partnerships, especially in the mining space. We are also actively fundraising to deploy for our first couple of projects beyond the pilot. We’re hyper-focused on the North American market, because it’s such a critical piece, I think, in creating a circular economy, and not only that, but really reducing the risk that the manufacturers here face, relying so heavily on overseas supply chains, because there will be a significant gap in the supply of all these materials. If we truly want to reach our goals of electrification over the next decade, and even beyond, we really need to find an alternative source.

This article appeared in Charged Issue 56 – July/Aug 2021 – Subscribe now.