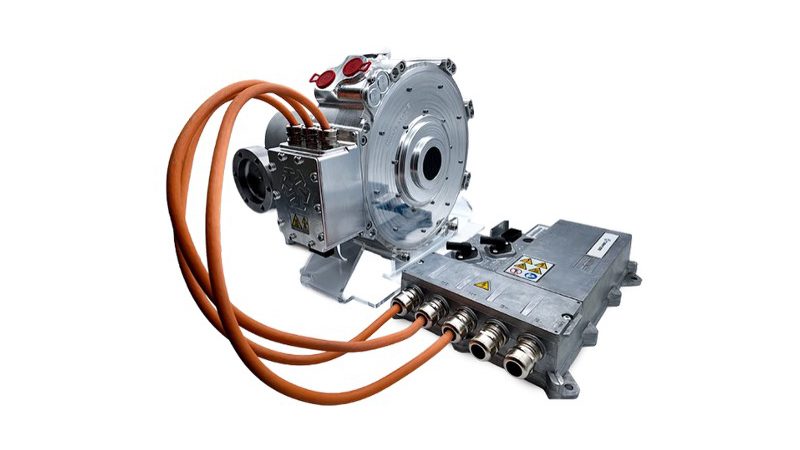

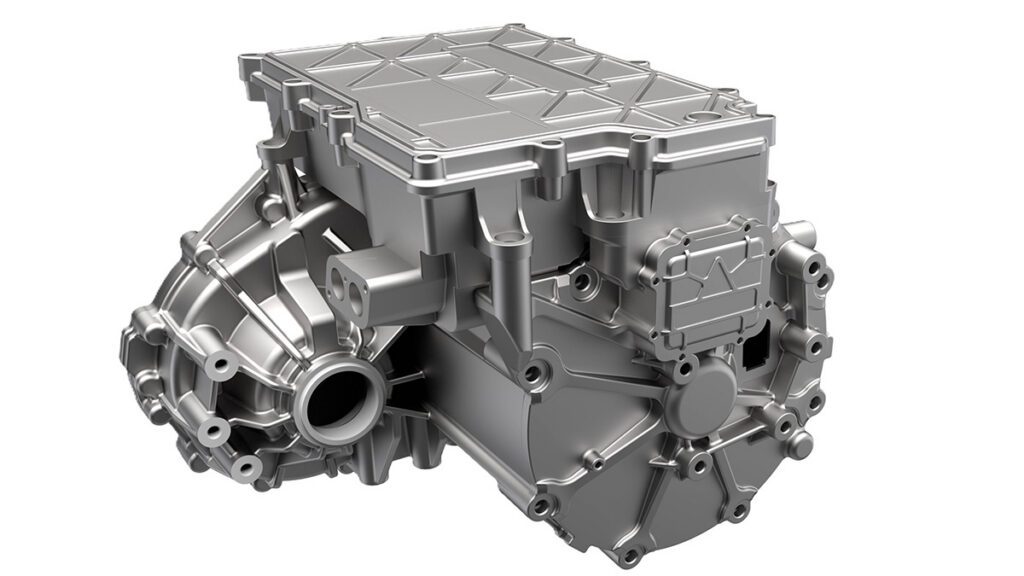

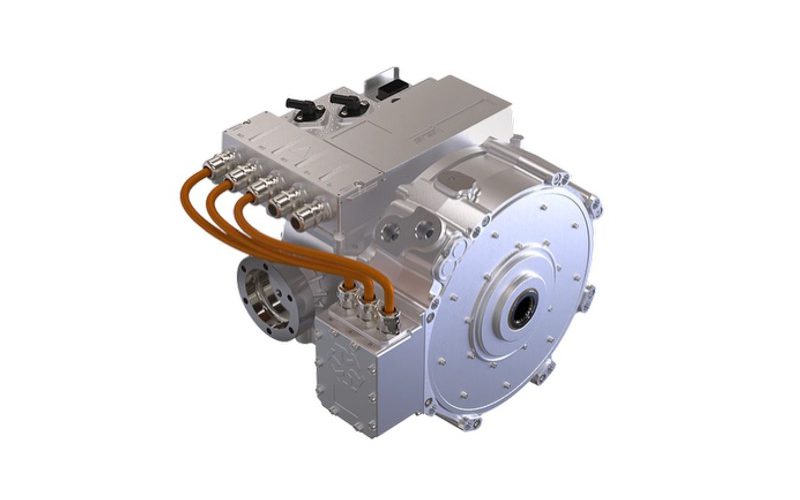

Turntide Technologies has unveiled a modular axial flux electric drive unit (EDU) that integrates motor, inverter and gearing with shared cooling in a single package. The company says the axial flux design delivers 53% higher torque density than a comparable radial flux motor in 58% less volume and at 37% less weight.

The platform supports 400 V and higher, with single or stacked motor configurations scaling from 73 kW to 220 kW nominal and 300 kW to 700 kW peak. Target applications include off-highway equipment, construction, powersports, commercial vehicles and automotive. The low-speed, high-torque characteristics of the axial flux motor allow for simpler gear designs, which Turntide says reduces mechanical complexity, weight and maintenance costs.

The company is positioning the EDU as a pre-validated platform aimed at OEMs looking to electrify without the component-level integration work that typically adds months or years to development programs. “By handling the integration, validation, and testing upfront, our EDU decreases the risk, time and cost of bringing new products to market,” said CEO Steve Hornyak.

Turntide recently put the platform through a durability test at King of the Hammers, one of the most demanding off-road races in the US. Its Sierra Echo-R became the first purpose-built EV to qualify for and compete in the Desert Challenge course, completing more than 600 miles of terrain with no drivetrain issues, according to the company.

Source: Turntide Technologies