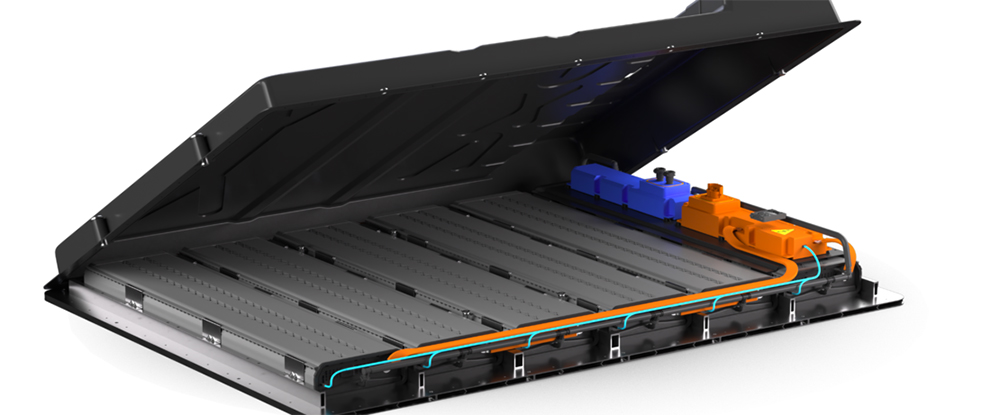

Germany-based Vestaro, a joint venture of specialty chemical provider Evonik and Forward Engineering, has launched a new generation of its EV battery packs. The new Pure Performance Battery pack is composed of a composite housing made with sheet molding compound (SMC) technology, a semi-integral modular design and LION Smart’s LIGHT battery cells.

Vestaro’s glass fiber battery pack cover is based on Evonik’s epoxy curing agent VESTALITE S. According to the company, the SMC materials deliver performance equal to that of previous metal-based enclosures, and substantially reduce weight.

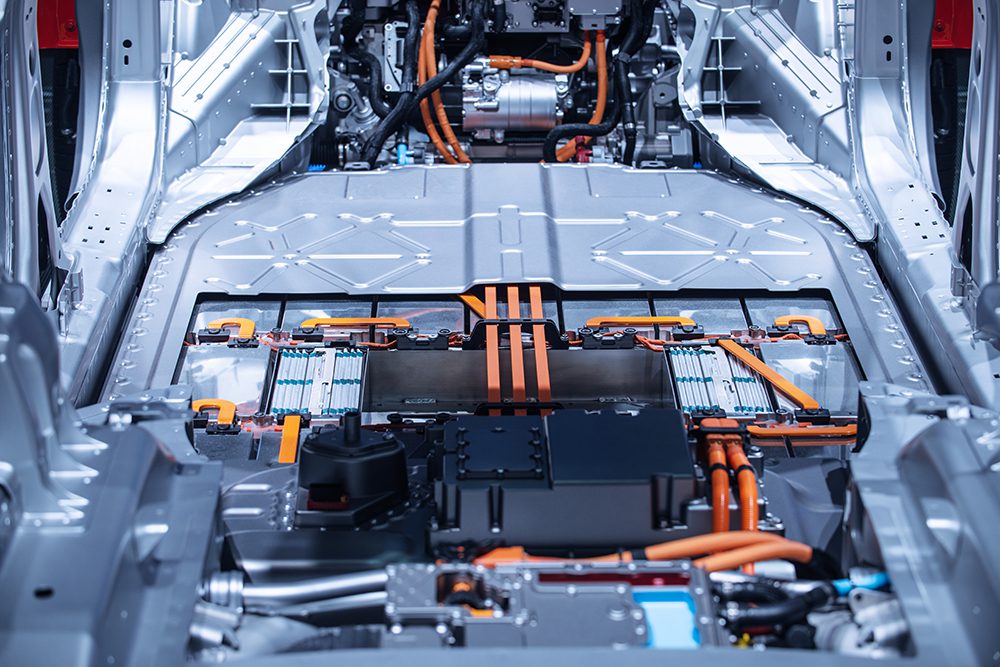

The new pack housing is designed to improve both bottom impact performance and vehicle integration. The designers took advantage of the design freedom of the versatile SMC material. The old bottom structure was replaced with an aluminum sandwich plate, which increases the performance in terms of the bottom impact, and also plays a key role in the semi-integral vehicle concept. The designers were able to remove the additional side deformation elements and use the freed space for more battery cells.

Also, due to the improved bottom impact performance of the sandwich floor, the space required for the module mounting could be reduced. The creation of these extra spaces for battery cells allowed the designers to increase capacity from 65 to 75 kWh, while retaining nearly the same outer dimensions as the group’s previous-generation battery pack.

“Our new battery pack is designed for performance, and it’s the exceptional properties of our VESTALITE curing agents that give the unique epoxy-SMC cover its outstanding performance and safety potential in terms of fire resistance and crash behavior,” said Evonik Marketing Director for Adhesives and Composites Sebastian de Nardo.

Source: Evonik