Since the advent of modern EVs, the mantra has been “cell/module/pack.” More recently, some battery makers have started removing modules from the equation with cell-to-pack architectures.

Now Massachusetts-based battery developer 24M Technologies wants to eliminate the whole hierarchy. The company calls its Electrode-to-Pack system, which it introduced at the recent Japan Mobility Show, “a streamlined battery pack system that features electrodes packaged directly into the battery pack, removing the need for individual cells and modules.”

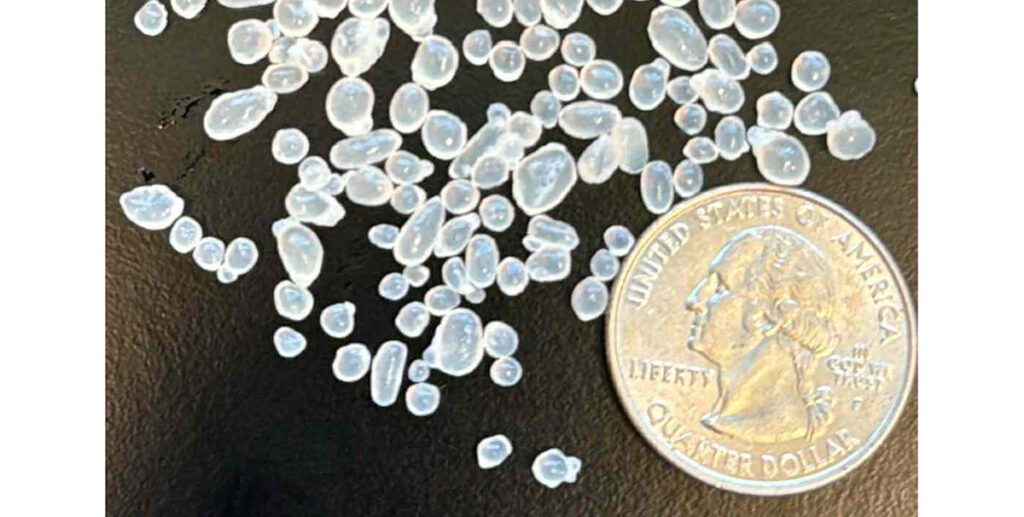

Current lithium-ion battery cells include substantial amounts of inactive, non-charge-carrying materials—supporting metals and plastics—within a cell’s casing, and these materials reduce energy density and add unnecessary expense and waste. 24M says its Unit Cell design allows manufacturers to eliminate unnecessary cell materials within the pack, enabling the highest energy density available at the pack level while cutting costs.

24M says its new technology enables unit electrodes to be connected in a combination of series and parallel. The 24M Unit Cell can be connected in series, parallel and a combination of series and parallel directly within a pack, enabling configurations that are no longer limited by individual cell voltage and capacity.

“24M ETOP will be a game-changer for electric mobility and energy storage systems because it delivers unmatched energy density,” said Naoki Ota, 24M President and CEO. “We are moving beyond our core technology—the 24M SemiSolid manufacturing platform—into a company with a revolutionary technology set that will deliver truly transformative solutions.”

Source: 24M

![New York City may replace Central Park’s horse-drawn cabs with electric carriages [Updated]](https://chargedevs.com/wp-content/uploads/2025/09/AdobeStock_273233016.jpg)