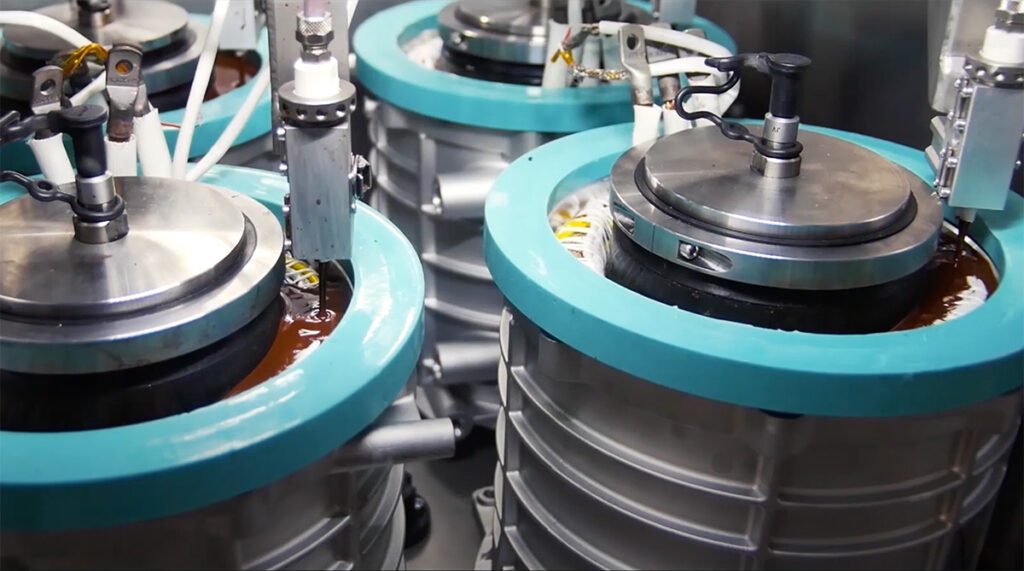

INFICON, a leak-testing device and instrument manufacturer, has released an upgraded electrolyte leak detector for in-line leak testing of batteries.

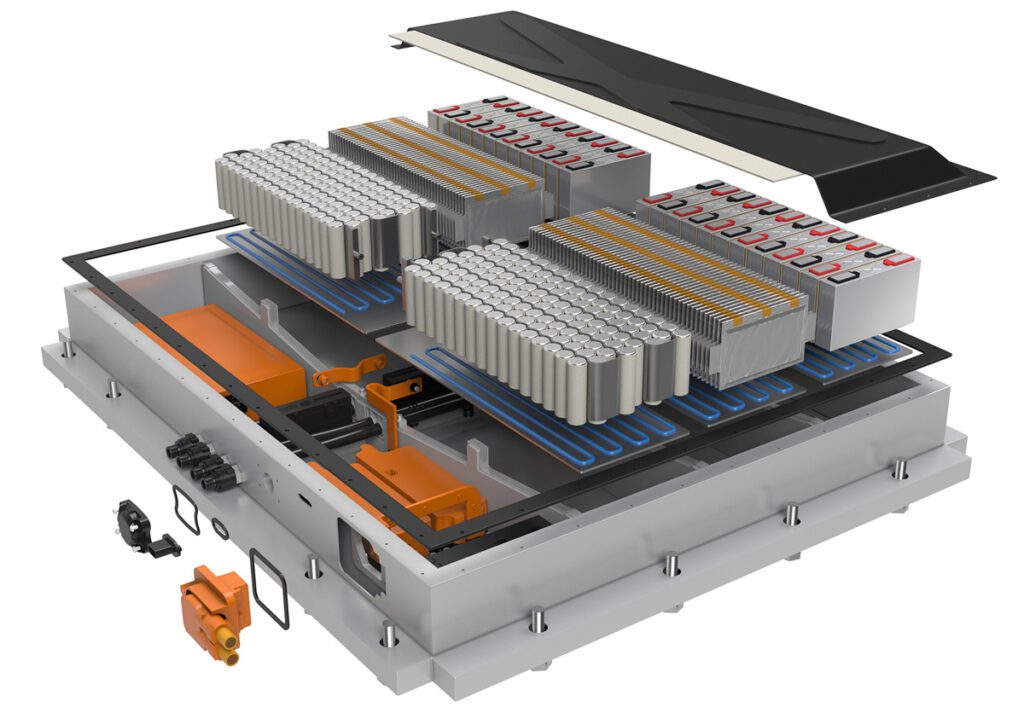

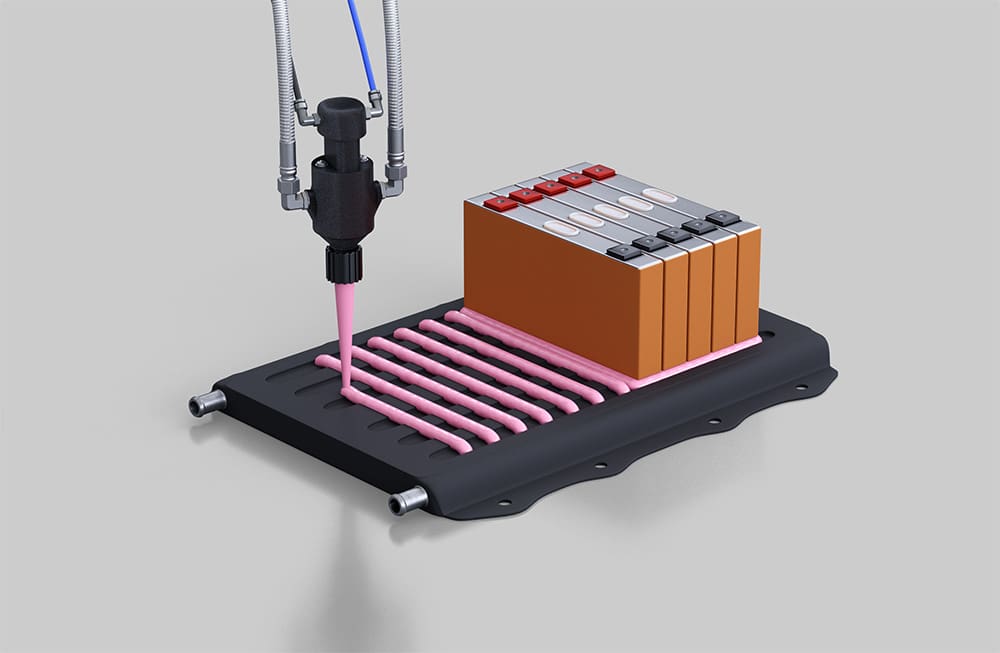

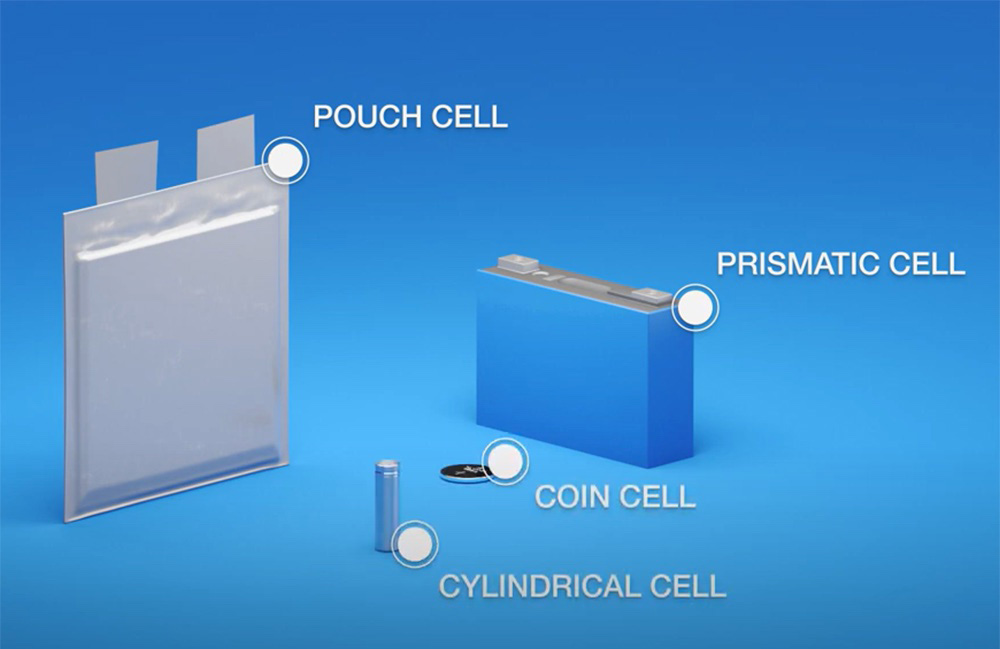

The ELT3000 PLUS directly detects electrolyte solvent leakage into a vacuum chamber to test ready-filled lithium-ion and sodium-ion batteries in all cell formats. It has manual and automatic in-line leak detection modes for fast cycle times and high throughput in series manufacturing, and can simultaneously test multiple cells. INFICON says it’s method identifies leaks with all cell formats, including prismatic, round or button cells and soft pouch cells.

With its automated calibration capability, the ELT3000 PLUS can monitor different electrolyte leakages in 30 seconds and transfer all test results to each plant’s quality system in real-time. The ELT3000 PLUS can evaluate leaks a few micrometers in diameter at 5.10-7 mbar.I/s (helium equivalent leak rate), reducing the risk of battery failure from water or humidity. The smallest detectable leak rate of its predecessor, the ELT3000, was 1.10-6 mbar.l/s.

“With its high throughput and accuracy, integrating the ELT3000 PLUS into the production line will add only seconds to cell production and it can save millions in costly recalls from malfunctioning lithium-ion battery cells,” said Thomas Parker, an INFICON Sales Manager. “The ELT3000 PLUS operates to ISO standards and can easily integrate into a lithium-ion battery cell production line.”

Source: INFICON