Imagine a hybrid vehicle that could not only heat a home when the power goes out, but that could also pull a bigger trailer than its non-hybrid brother while using less fuel. Ford Motor Co. did just this with the new 2021 F-150.

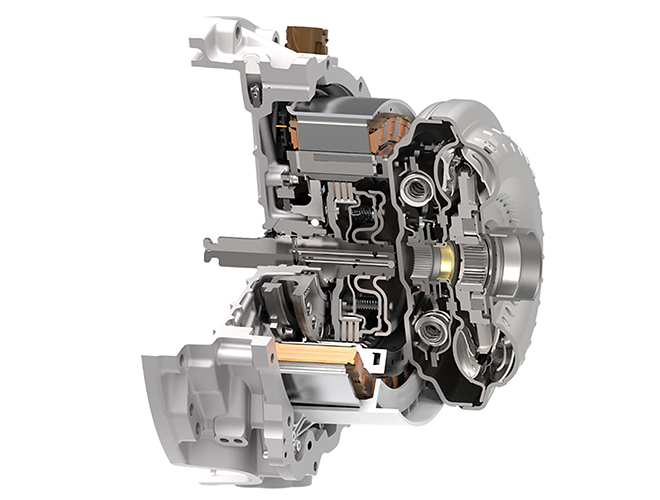

To enable that hybridization, Schaeffler designed and industrialized a hybrid module that could be mated with Ford’s 10R80 transmission. The P2 Hybrid Module (P2 refers to its placement between the engine and transmission), can be used to generate electricity for powering homes, job sites, camp sites, tailgates or any remote location; it can be used to propel a vehicle in pure electric mode; and it can be used in conjunction with the gasoline engine to increase towing and straight-line performance.

Schaeffler’s P2 Hybrid Module—a parallel hybrid—is garnering notable praise in the mobility industry for its host of features and benefits. It earned a coveted Automotive News 2021 PACE Award for its superior innovation, technological advancement and business performance.

A case for parallel hybrids

Stricter regulations in the US are demanding fuel economy improvements to all vehicles. For years, customers had two powertrain options:

- Powerful engines that deliver standard fuel economy; or

- Low-power engines that deliver improved fuel economy.

This leaves vehicle manufacturers with a dilemma: how can the fuel economy be improved without compromising performance? A parallel hybrid arrangement—where fuel economy is improved—is the solution.

With a parallel hybrid, an electric motor is added to a conventional drivetrain. This type of arrangement adds the power from the electric motor to the power of the internal combustion engine. It delivers a no-compromises solution where vehicle performance is improved relative to the same vehicle with a traditional internal combustion engine.

A disconnect clutch is placed between the internal combustion engine and the hybrid transmission. This disconnect clutch allows the engine to be turned off during light driving events when the electric motor has enough power to meet driver demands. It also allows for integration of regenerative braking with a traditional powertrain and increasing fuel economy.

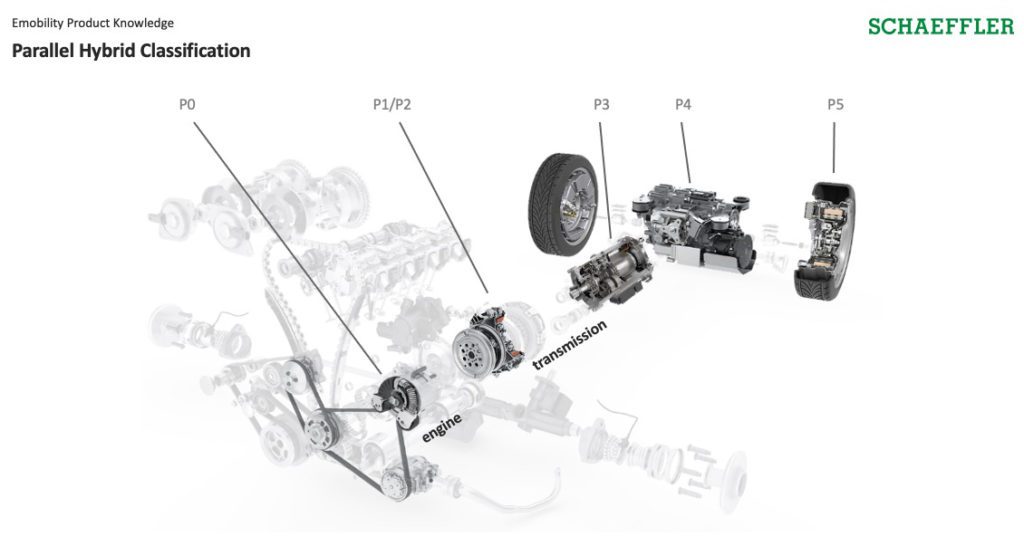

There are different places that an electric motor can be placed to deliver a parallel hybrid vehicle. Schaeffer designed a P2 Hybrid Module that is mounted in between the engine and transmission to house the electric motor and disconnect clutch, while keeping space demands to a minimum and retaining the majority of the conventional powertrain.

Tight integration of the torque converter with the electric motor reduces the overall length of the hybridized transmission. This allows the transmission to fit in more vehicle platforms and keeps manufacturing complexity to a minimum. It also allows for as much re-use of current transmission hardware and software reducing customer system integration efforts. Through innovative engineering and system expertise, Schaeffler engineered a next-generation hybrid system that is taking the mobility industry by storm.

For more information visit: www.schaeffler.us