Over the next decade, technology is expected to trend towards an all-electric society – a world with unlimited energy based on renewable resources without harmful emissions. This will be seen in a variety of verticals, from consumer devices to lawnmowers, drones and all types of vehicles. The trend of electrification is driven by a desire to reduce carbon emissions, advances in technology, and government mandates and investment in electric vehicles. The ability to both reduce carbon emissions from internal combustion engines and invest in clean energy transportation has become a widespread goal for government and industry alike.

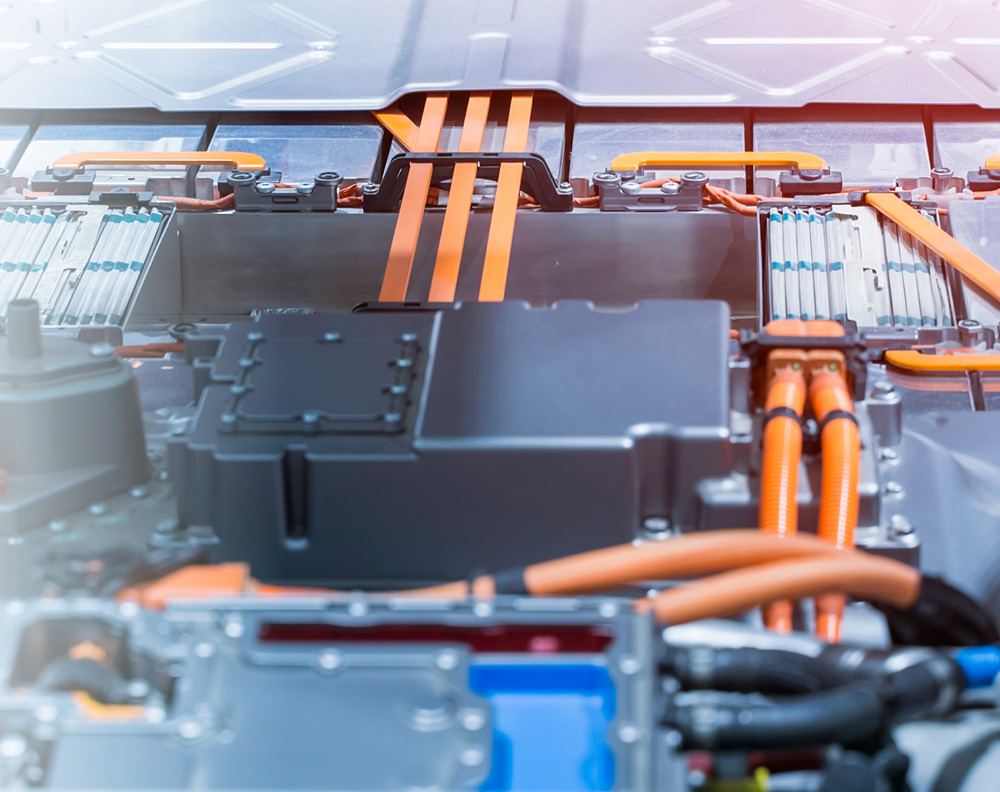

By 2025, an estimated 60% of vehicles offered by automakers in the United States will have electric components. This trend will be driven in large part by investment into the critical components that make electric vehicles safe, reliable and functional, including the battery management system. This system oversees management of safety, electrical and thermal operations, as well as data acquisition and communication to the user interface. The battery management system is the brains behind the battery pack, allowing it to optimize battery efficiency and maximize range.

INTERCONNECT DESIGN CONSIDERATIONS

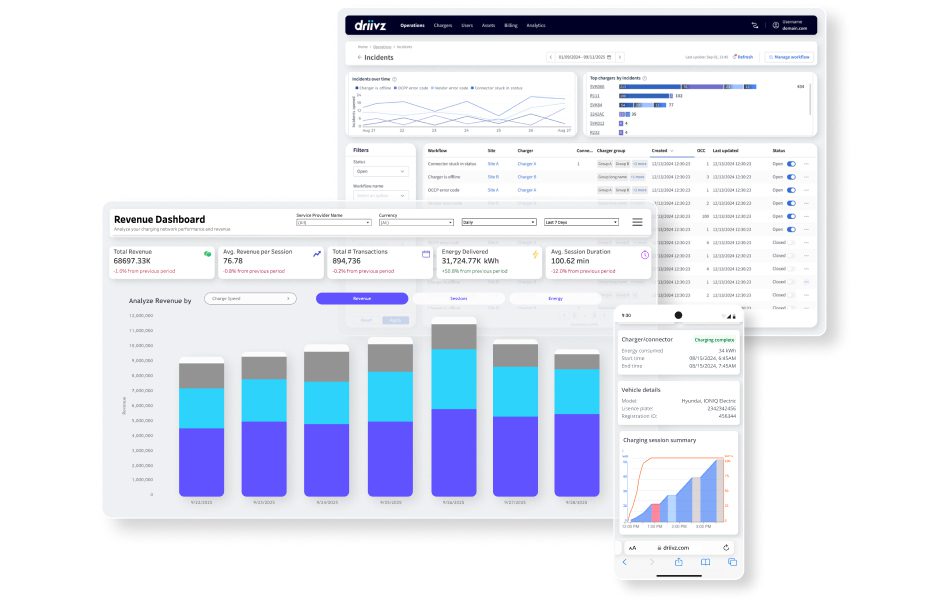

The interconnect solutions within a battery management system are essential to monitoring efficiency, health and operational systems and communicating that data to the appropriate channels. Interconnects pass along critical information to other sensors – for example, sensors that detect gas leaks as well as heat and pressure levels that detect the health of every component of the battery. These components also communicate battery operations and safety concerns to the user, giving them confidence in and control over the status of the electric vehicle.

Due to their role, interconnects are a critical component to the safe operation of an electric vehicle, and a loss of connectivity in the battery management system could be catastrophic – any compromise to the systems could be deadly. Because of this, interconnects used in electric vehicle battery management systems must meet a number of requirements, including:

- Accuracy

- Reliability

- Robustness

- Failsafe

- Vibration resistant

- Automotive grade

- Compact

- Lightweight

- Safe from short circuiting

- Flexibility

- Meet automotive-grade standards

- Withstand temperature extremes

Specifically, interconnect components must be able to withstand the harsh environment present inside an electric vehicle while maintaining a small footprint and flexible components to fit inside tight spaces.

BATTERY MANAGEMENT SYSTEM COMPONENTS AND SOLUTIONS

Original equipment manufacturers have taken multiple approaches to solving these interconnect challenges that regulate the health and communication of the battery cells. Traditionally, battery packs have wires coming into the receptacle side of the solution, and the board side sits on a printed circuit board. Currently, though, designers are shifting away from that approach and towards using flex wires.

There are pros and cons to both strategies – flex circuits offer significantly lower weight and can overcome the complexity of right routing. However, flexible printed circuits cannot cope with any water. While this isn’t an issue within a battery management system, flex circuits could also be used in other areas of an electric vehicle that could be exposed to water.

Whether an interconnect solution uses a flex circuit or wire to board component, it must meet the industry qualifications required for it to be used in an automotive environment. Automotive-grade interconnects should be equipped with a locking or latching mechanism to ensure it stays connected even with heavy vibration, a sealed or waterproof configuration if it’s used along the outside the vehicle, and connector position assurance to ensure mating reliability and secure electrical connections.

AMPHENOL OFFERS AUTOMOTIVE-GRADE INTERCONNECTS

Amphenol offers a variety of interconnects designed specifically to facilitate monitoring and communication within a battery management system – a critical component to the safe operation of an electric vehicle. Regardless of how the battery management system is built, Amphenol’s portfolio of connector technology is designed to meet the requirements of the automotive industry. Amphenol’s partnership with TTI ensures that customers have access to the inventory of these critical components as well as design assistance.