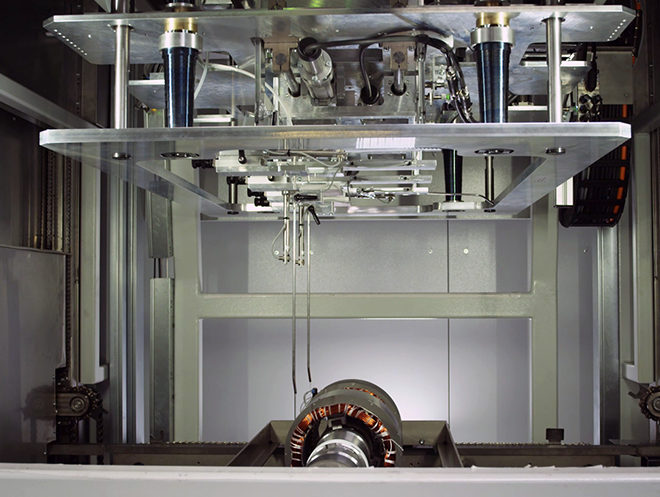

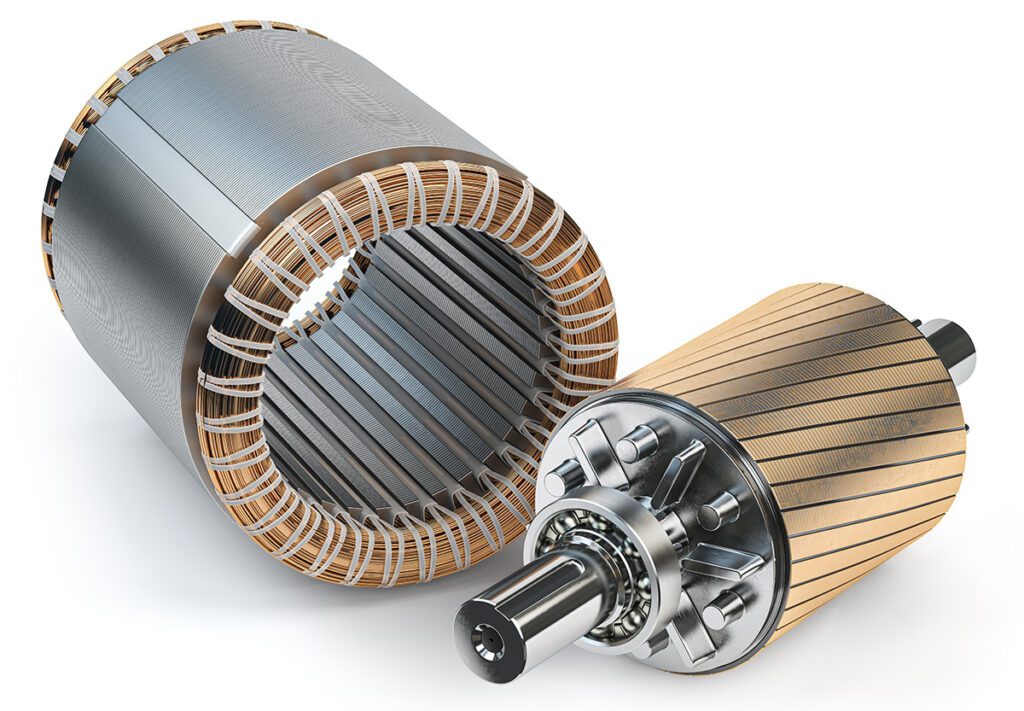

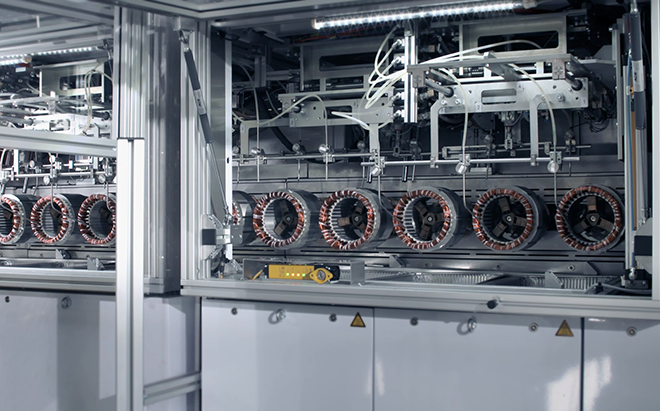

bdtronic, a German mechanical engineering company and process specialist, will provide ZF Friedrichshafen with another trickle impregnation machine for electric motor production. ZF is already using bdtronic systems at several locations worldwide, and is now ordering the next machine for the trickle impregnation of hairpin stators. The stators will be used for front- and rear-wheel drive powertrains made by a European EV manufacturer.

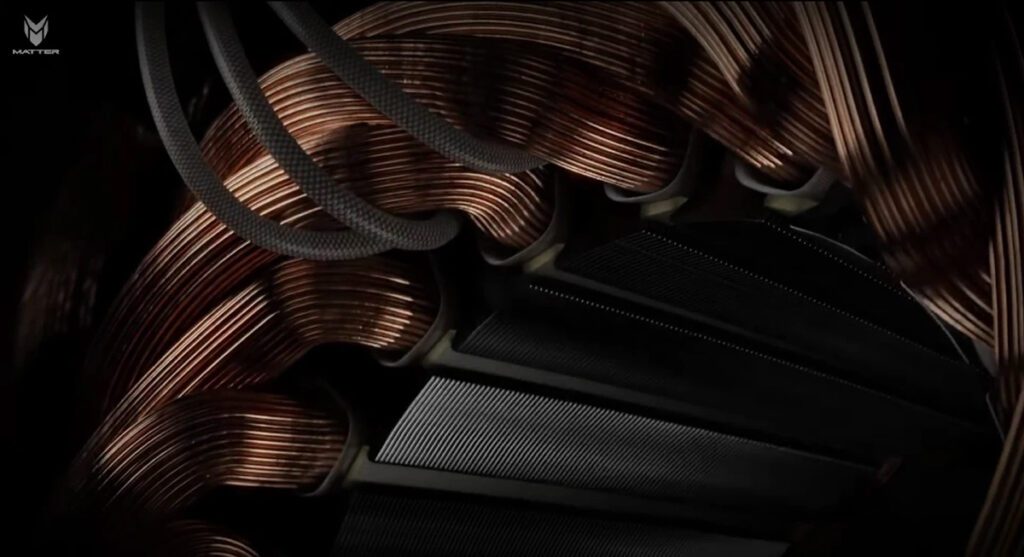

“bdtronic is the global market leader for high-volume trickle impregnation machines for EV motors. Every trickle-varnished stator of an EV sold in Europe this year has been produced on a bdtronic machine,” said CEO Patrick Vandenrhijn. “We have established a longstanding and stable partnership with ZF Friedrichshafen. The clean process of trickle impregnation helps our customers to achieve their sustainability goals. The material consumption compared to other impregnation methods (e.g. dipping) can be reduced up to 30 percent. Not only is the material waste reduced to zero, but energy consumption and floor space are significantly lower, and subsequent cleaning processes are not required.”

Since 2008, bdtronic has offered different machine concepts for the impregnation of EV motors, especially with the trickling process. The machines can process different kinds of stators and impregnation resins, depending on the customer’s needs. The company has built impregnation machines for OEMs and Tier 1 suppliers for the European, Asian and North American markets.

Source: bdtronic