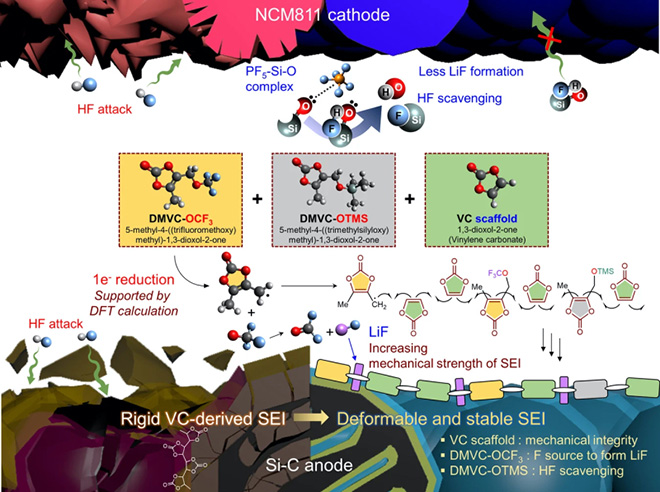

Researchers at the Ulsan National Institute of Science and Technology (UNIST) in Korea say they have developed an electrolyte additive that enables a high-energy-density Li-ion battery to retain more than 80% of its initial capacity, even after hundreds of cycles.

In a paper published in Nature Communications, the scientists reported that when the substance was added to a large-capacity battery composed of a high-nickel anode and a silicon mixed anode, the initial capacity was maintained at 81.5% even after 400 charging and discharging cycles—10% to 30% better than commercial additives such as FEC (fluoroethylene carbonate) or VC (vinylene carbonate).

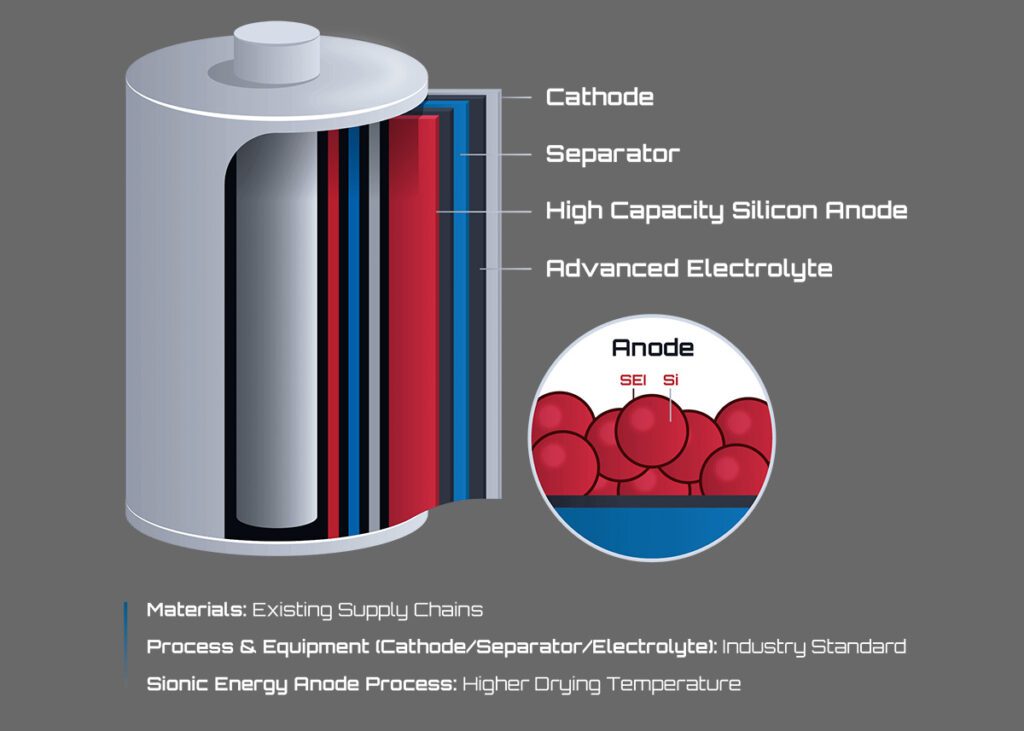

As the demand for large-capacity batteries increases, research to replace electrodes in commercial lithium-ion batteries with high-capacity materials such as silicon and high nickel is active. However, the volume of silicon anodes is increased by three times or more during charging and discharging, so mechanical durability is weak, and high nickel anodes are also chemically unstable.

Researchers say the protective film made by the new dioxolone additives has good elasticity and facilitates lithium ion permeability (mobility). This enables high-speed charging and reduces the mechanical overload caused by the repeated volume changes of silicon.

In addition, the additive removes hydrofluoric acid (HF) from the electrolyte to prevent the metal (nickel) inside the high nickel anode from leaking out.

Source: UNIST via Green Car Congress