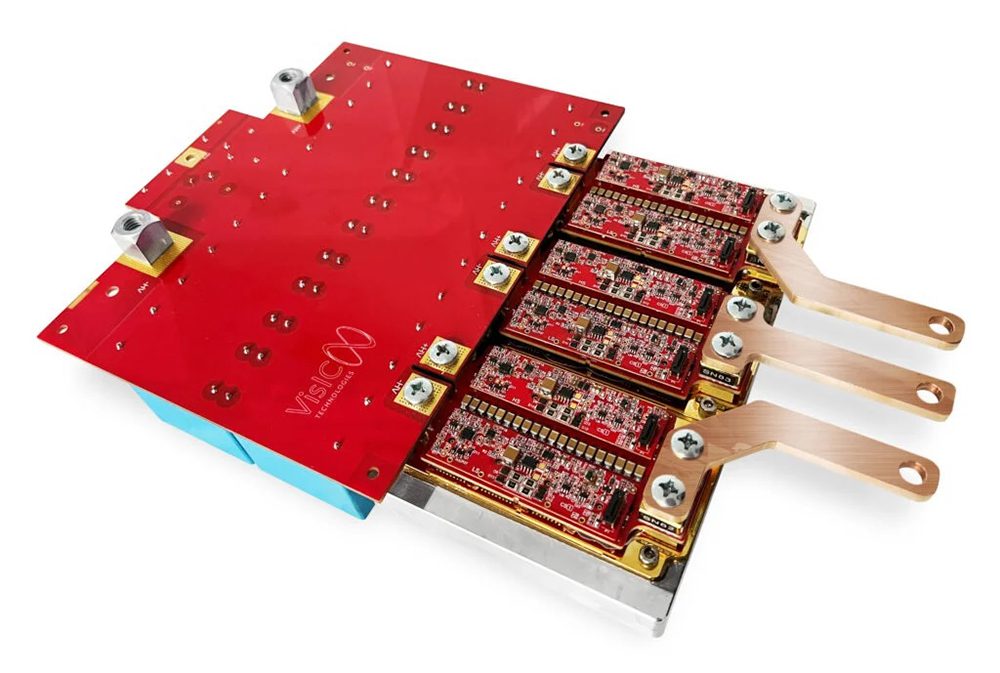

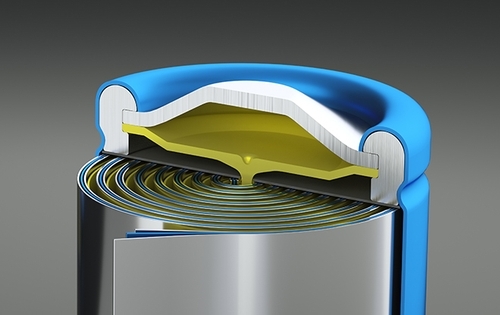

Ultium Cells, a joint venture between General Motors and LG Energy Solution, will upgrade its Spring Hill, Tennessee battery cell manufacturing facility to scale production of low-cost lithium iron phosphate (LFP) battery cells, building on a $2.3-billion investment announced in 2021. Conversion of battery cell lines at Spring Hill to produce LFP cells will begin later this year, and commercial production is expected to begin by late 2027.

GM has designed its current EV platform to enable the quick integration of different cell chemistries and form factors. The Ultium Cells plant in Warren, Ohio will continue producing cells with a nickel cobalt manganese aluminum chemistry, which GM uses in its longer-range EVs. The LFP battery technology, by contrast, tends to offer lower energy density but also lower cost.

“At GM, we’re innovating battery technology to deliver the best mix of range, performance and affordability to our EV customers,” said Kurt Kelty, VP of Batteries, Propulsion and Sustainability at GM. “This upgrade at Spring Hill will enable us to scale production of lower-cost LFP cell technologies in the US, complementing our high-nickel and future lithium manganese rich solutions and further diversifying our growing EV portfolio.”

“The upgrade reflects the continued strength of our partnership with General Motors and our shared commitment to advancing EV battery innovation,” said Wonjoon Suh, Executive VP at LG Energy Solution. “We will bring our extensive experience and expertise in US manufacturing to the joint venture facility, further accelerating our efforts to deliver new chemistries and form factors that effectively capture the unmet needs in the EV market.”

Source: GM