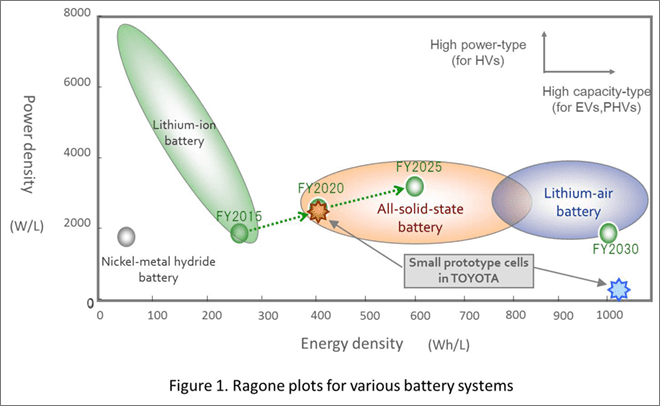

As Toyota plans to bring a fuel cell vehicle to market in 2015, its researchers continue to work on next-generation battery technologies. In a presentation at the International Meeting on Lithium Batteries in Como, Italy, Dr. Hideki Iba from Toyota’s Battery Research Division and Dr. Chihiro Yada from Toyota Motor Europe’s Advanced Technology Group noted that, while lithium-air batteries may not be commercialized until 2030, solid-state batteries could be ready for the market as soon as 2020.

The Japanese automaker has already developed prototype cells with an energy density of 400 Wh/L, and built a prototype electric kickboard powered by an all-solid-state battery.

Image courtesy of H. Iba (Toyota Motor Corporation) and C. Yada (Toyota Motor Europe NV/SA)

Image courtesy of H. Iba (Toyota Motor Corporation) and C. Yada (Toyota Motor Europe NV/SA)

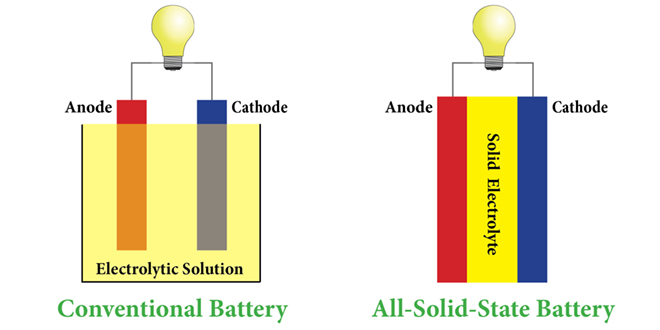

Solid-state lithium-ion batteries offer long cycle life, as well as higher volumetric energy densities than current Li-ion designs. They also can be packaged more efficiently, as the cell design can allow in-series stacking and bi-polar structures, and could be safer, as there is no risk of leakage of a liquid electrolyte, and the inflammable and inorganic solid electrolytes have high thermal stability.

As reported in a paper in ATZ elektronik worldwide, Dr. Yada and co-author Claudia Brasse noted that, until recently, solid-state Li-ion batteries have suffered from limited power densities, partly due to the large lithium-ion transfer resistance at the interface between cathode and solid electrolyte. Therefore, researchers are concentrating on developing better lithium-ion-conducting solid electrolytes, designing improved electrode/electrolyte interfaces to reduce interfacial resistance, and improving Li-ion conductivity in active materials.

“All-solid-state lithium-ion batteries have been considered as innovative new-generation batteries despite their long history,” write Yada and Brasse. “However, there remain many issues to be solved and their practical application seems limited at the present stage. Needless to say, electrode/electrolyte interfaces are very important sites to start and carry out the electrochemical reaction. Using the latest technology including advanced analyses, nano-structural adjustments of the interfaces will become a clue and breakthrough to resolve many issues.”

Source: Green Car Congress