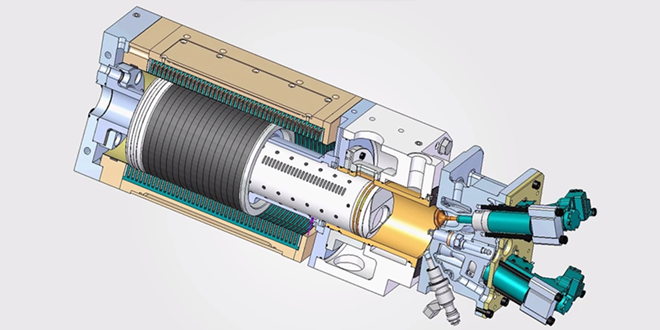

Unlike a traditional ICE, which propels a drive shaft, a free piston engine linear generator (FPEG) is designed to generate electricity directly. Magnets attached to the piston move within a linear coil, converting kinetic energy to electrical energy.

A team from Toyota Central R&D Labs presented a prototype FPEG to the SAE in 2014. Now the Toyota researchers have developed a new FPEG control method that improves the stability and flexibility of the piston motion control.

In “Development of Free Piston Engine Linear Generator System Part 3—Novel Control Method of Linear Generator for to Improve Efficiency and Stability,” presented at the recent 2016 SAE World Congress, Kaznunari Moriya and colleagues explain that they had developed a target positon feedback control method, which worked well at low power, but was not able to maintain the piston swing motion when output power was increased. To address this issue, the team developed the new method, called “resonant pendulum” control.

“There are some technical challenges in ensuring an FPEG can achieve continuous operation over a long period,” write Moriya and his team. “Among these challenges, the piston motion control is the most significant factor in improving the robustness and efficiency of the FPEG because the combustion characteristics depend strongly on the piston motion, which is controlled by the linear generator. This paper describes a novel linear generator control method which realizes the simple harmonic oscillation governed by the piston mass and the air spring pressure.”

Source: Toyota via Green Car Congress