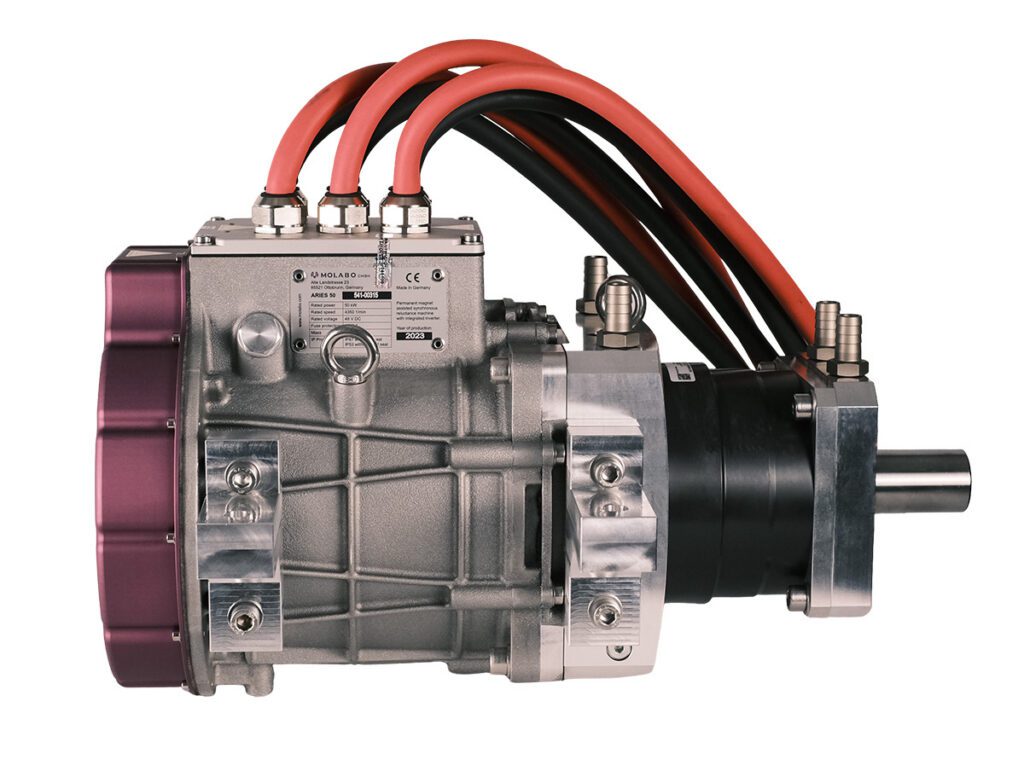

FEV has announced a collaboration with the Teaching and Research Area Mechatronics in Mobile Propulsion at RWTH Aachen University to develop a modular electric drive unit platform aimed at reducing reliance on rare-earth elements in EV motors.

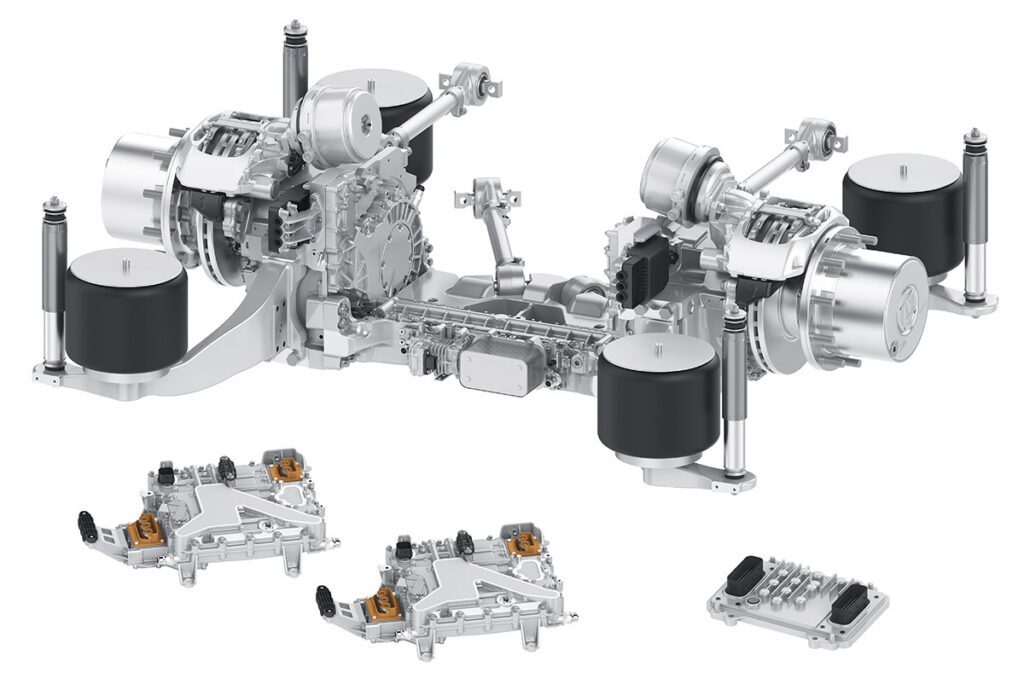

The new platform minimizes the use of critical raw materials such as rare-earth magnets, with the goal of eliminating them entirely. The developed concept features a modular architecture comprising a shared stator, housing, cooling system, and converter, with interchangeable rotors.

FEV says that technical studies demonstrate rare-earth-free alternatives can achieve overall efficiencies up to 94 percent, while lowering cost volatility and reducing carbon dioxide equivalents over the motor’s lifecycle.

To evaluate performance and cost, engineers from FEV and RWTH Aachen University investigated electrically excited synchronous machines, ferrite-based electric machines and asynchronous machines as alternatives to traditional permanently excited synchronous motors with rare-earth magnets.

The platform targets mid-range (C segment) and luxury (D segment) EVs, supporting peak outputs of 160 kW and 250 kW, and can be adapted for lower vehicle segments through its modular design.

FEV says the platform’s oil cooling system with direct stator and rotor cooling enables a substantial increase in continuous power output. The ratio of continuous to peak power surpasses conventional systems by up to 75 percent.

“Our platform approach allows vehicle manufacturers to react faster and more flexibly to market shifts, raw material shortages, and cost fluctuations, “said Patrick Hupperich, President and CEO of FEV Group. “This is achieved without compromising efficiency or performance.” The modular platform allows original equipment manufacturers to accommodate different drive concepts simply by changing the rotor, streamlining development and improving supply chain diversification.

Source: FEV