The world car has been a reality for many years now. Automakers source parts and expertise from around the world, and they build vehicles in different regions to be closer to markets or to take advantage of cheaper labor. Buying American is a worthy cause, but it isn’t as simple as buying an American brand.

The Kogod School of Business at American University issues an annual study that tries to sort through the complex international web of auto production, and ranks cars according to how “made in America” they really are. Its 2016 findings are based on the proportion of American parts, labor and R&D efforts that go into each particular vehicle model.

Some will be surprised to learn that several models from Honda and Toyota are more than 76% American-made. The iconic Chevrolet Corvette is 83% American-made, and the USA’s best-selling vehicle, the Ford F-150 pickup truck, is (cue the Stars and Stripes, waving in the breeze) 85% American-made. The most all-American vehicles are the Buick Enclave, the Chevrolet Traverse and the GMC Acadia, each 90% made in the USA.

However, a certain California carmaker may soon be the reddest, whitest, and bluest of them all.

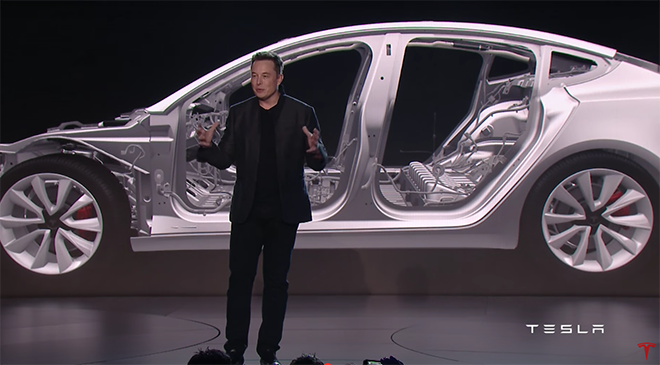

Tesla has always celebrated its patriotic bona fides. Elon Musk has described himself as “nauseatingly pro-American.” The company has made a special point of hiring military veterans. And of course, at a time when many are lamenting the decline of American manufacturing, what could be more patriotic than employing over 25,000 Americans in a rapidly growing, future-oriented industry?

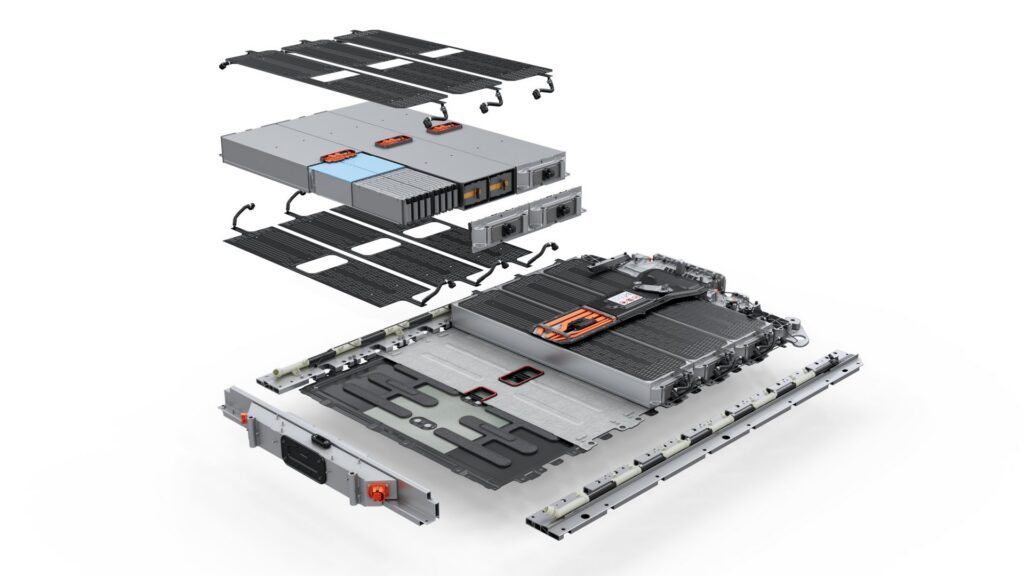

At the moment, Model S is far out of Kogod’s top tier of Made in the USA vehicles – according to Tesla, about 55% of its components are US- or Canadian-made. Once the Gigafactory ramps up to volume production however, that proportion is expected to soar like a rocket (cue the red glare).

When Tesla begins using its new 2170 battery cell, which for Model 3 is expected to happen in the second quarter of this year, its vehicles will be 95% made in the US, making them the “most American” cars available.

Panasonic continues to produce battery cells in Japan and elsewhere, but will be steadily expanding production at the Gigafactory in Nevada. Tesla also plans to source much of the raw materials in those cells from the US. The company is believed to be developing a source of lithium at Silver Peak, not far from the Gigafactory, and Nevada lawmakers have proposed new tax incentives aimed at increasing lithium production in the state.

Of course, Tesla’s decisions to keep production close to home aren’t made only for patriotic reasons – they have to do with access to skilled workers, and keeping supply chains short. But with environmental regulations – especially the CAFE standards that encourage automakers to produce EVs – on the chopping block in Washington, it surely can’t hurt to be able to point to the huge economic benefits of maintaining America’s leadership in the EV industry.

Source: Kogod School of Business, Motley Fool, Electrek