Redwood Materials, the battery recycling venture founded by former Tesla CTO JB Straubel, came out of stealth mode last year, and announced that it is recycling scrap from Panasonic’s battery cell production at Tesla’s Gigafactory Nevada. In July, it raised $700 million in new investment.

Now Redwood has dropped a bit of a bombshell: it isn’t just interested in recycling, but also has plans to build one of the world’s largest battery materials factories. “We’ve shared a lot about our recycling work which is certainly a core component of the battery sustainability equation but is only the tip of the iceberg for Redwood,” the company announced in a press release.

“Closing the loop” to create a circular battery supply chain will mean “not just collecting and recycling the batteries but also continuing further, fully refining the materials we recover and then manufacturing them back into precision battery materials to use those raw materials again.”

This will be a win not only for US industry, but for the environment as well. “The existing battery supply chain is a convoluted system that requires materials to travel tens of thousands of miles before they make their way into a final product,” Redwood tells us. “In looking at the supply chain for a single component such as a cathode, the logistics required alone contribute enormously to the overall cost and carbon footprint.”

For starters, Redwood plans to supply battery cell manufacturing partners with anode copper foil and cathode active materials, produced from “as many recycled batteries as available and augmented with sustainably mined material.”

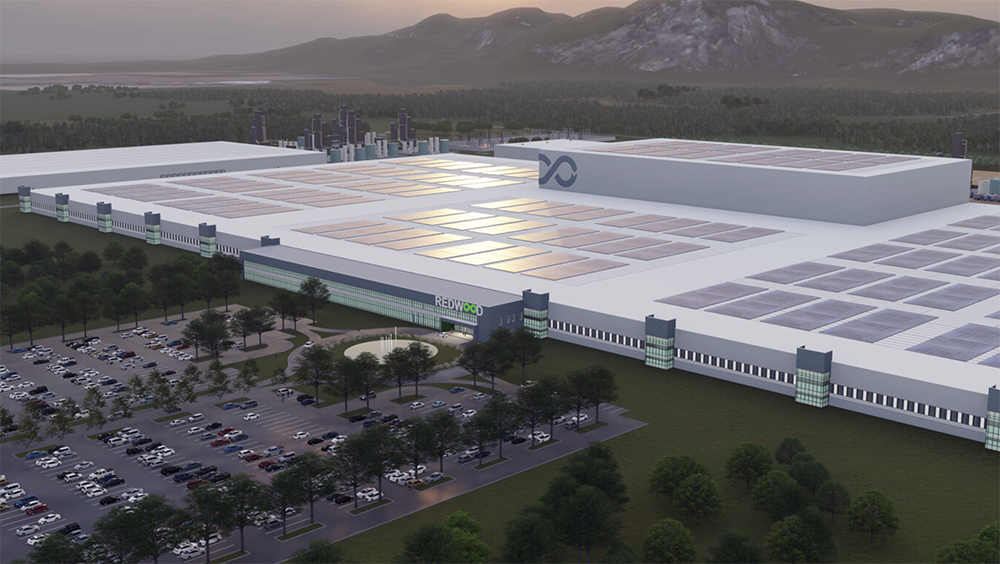

“By early 2022, Redwood will announce a site for our North American battery materials manufacturing facility, aiming to produce 100 GWh/year of cathode active materials and anode foil for one million electric vehicles by 2025,” says the company. “By 2030, we expect our production output to scale to 500 GWh/year of materials, which would enable enough batteries to power five million electric vehicles.”

According to Bloomberg, producing 100 GWh/year would make Redwood a major US producer of cathodes, the equal of the largest producers in Asia. The company expects to invest over $1 billion in the new facility.

“These numbers sound insane, but when you look at what the market needs, I’m like holy cow—is this even aggressive enough?” Straubel told Bloomberg. “Somebody’s got to do this. In fact, we need at least four companies doing similarly aggressive, crazy things all in the same timeline.”

Redwood does its recycling at its HQ in Carson City, Nevada, and recently broke ground on a 100-acre site in Story County, Nevada, to make copper foils. A cathode plant will be its biggest endeavor by far, Straubel says.

Bloomberg NEF analyst James Frith calls Redwood’s move into cathode production “a major development for the EV industry. Not only is the cathode the biggest driver of costs, but it’s the most polluting part of battery production. Consolidating the supply chain in the US will dramatically reduce emissions from battery production.”

The eventual goal is to make close to 100% of batteries from recycled materials, but that won’t be possible until there’s a large number of end-of-life EV batteries available. Today, EVs account for less than 10% of Redwood’s recycling stock. “We’re going to push the recycled percent as high as possible, but that is really going to be dependent on the availability of recycled materials,” Straubel tells Bloomberg. “If we end up consuming 50% or more of virgin raw materials, that’s fine.”

Consumer electronics will help fill the gap between now and when the first wave of EVs reaches retirement. Cells from consumer electronics contain considerably higher levels of cobalt than those used in EVs. For example, it would take 6,147 recycled iPhone batteries to provide enough lithium for a Tesla Model Y, but just 166 iPhones to provide enough cobalt, according to BNEF. Straubel says there’s enough cobalt in old electronics to supply its needs from recycling alone.

According to Bloomberg. Redwood has taken over half the US market for battery recycling. It has recycling agreements with Best Buy, Amazon, electric bus-maker Proterra, and Electronics Recycling Services, which claims to be the largest electronics consolidator in North America. More than 95% of the core battery materials are recycled, according to Redwood.

Sources: Redwood Materials, Bloomberg, Electrek