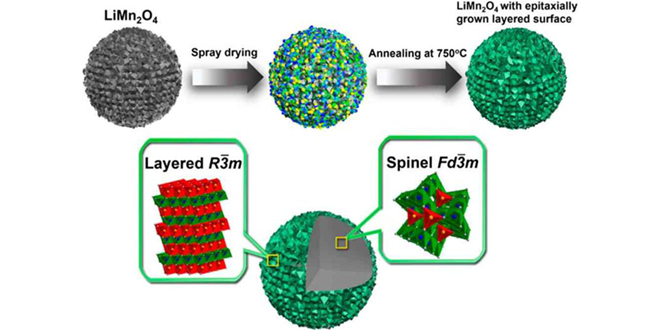

The quest for the better battery involves ongoing research on improving and optimizing materials used for lithium-ion cells. One such material is LiMn2O4 (LMO), which offers high power and low cost, but cell life at high temperatures can be problematic. In a paper in Nano Letters, a team from the Ulsan National Institute of Science and Technology (UNIST) in South Korea reports on a new LMO material that retained 85% of its capacity at 60° C after 100 cycles.

“LiMn2O4 is one of the most promising cathode materials for EVs due to its low cost, abundance, environmental affinity, and low safety hazard,” wrote Dr. Jaephil Cho and his colleagues. “However, it still suffers from a fast capacity fading at 60° C because the manganese on the surface of the LiMn2O4 dissolves in the liquid electrolyte solution containing acidic species. To solve this problem, many researchers have attempted to have the LiMn2O4 surface coated by inorganic materials such as Al2O3, AlPO4, AlF3, ZrO2, and SiO2. The coating materials acted as a protective layer that prevents the host LiMn2O4 from being exposed directly to the electrolyte. However, the coating layer also acted as a resistance layer when its thickness is too large, which results in deteriorating electrochemical performance. For this reason, electrochemically and electrically active materials have been considered as potential coating candidates for the LiMn2O4 cathode.”

Cho’s group has found that an electrically conductive carbon coating on the surface of the LiMn2O4 was effective, but its electrochemical performance deteriorated rapidly at high temperatures. What’s needed is a new approach to designing an optimized coating layer for the LiMn2O4 cathode that can be operated in high-temperature environments.

“In addition to morphology, thickness, and electronic and electrochemical properties, the coating layer needs to satisfy an additional requirement such as a chemical affinity between a host material and a surface layer. This condition may provide a better sustainable coating layer on its host cathode material without forming any crystal defect so that it can be operated in a harsh environment for a longer time. For this reason, the Mn-rich layered phase has been considered as one of the potential coating candidates for the LiMn2O4 cathode. The Mn rich layered phase that consists of Mn4+ such as LiNi0.5Mn0.5O2 was additionally considered to eliminate the possibility of the Mn2+ dissolution in electrolyte. After many experimental trials and errors, herein, we reported a new class of the heterostructured spinel cathode.”

Source: Green Car Congress

Image: ACS, Lee et al