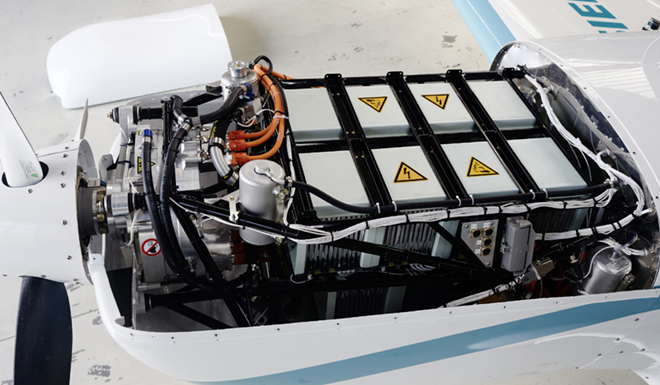

Siemens researchers have developed a new type of electric motor that delivers a continuous output of about 260 kW and weighs 50 kg. The new drive system, designed for a joint project of Siemens and Airbus to develop electrified aircraft, recently made its maiden flight in an Extra 330LE aerobatic airplane.

“This day will change aviation,” said Frank Anton, Siemens’ head of eAircraft. “This is the first time that an electric aircraft in the quarter-megawatt performance class has flown.” The Extra 330LE, which weighs about 1,000 kg, is particularly well suited to serve as a flying test bed for the new propulsion system.

Siemens and Airbus plan to use the new motor as a basis for developing regional airliners powered by hybrid propulsion systems. “By 2030, we expect to see initial aircraft with up to 100 passengers and a range of around 1,000 kilometers,” said Anton.

SEE ALSO: Airbus and Siemens collaborate on hybrid electric propulsion systems for aircraft

Source: Siemens via Green Car Congress