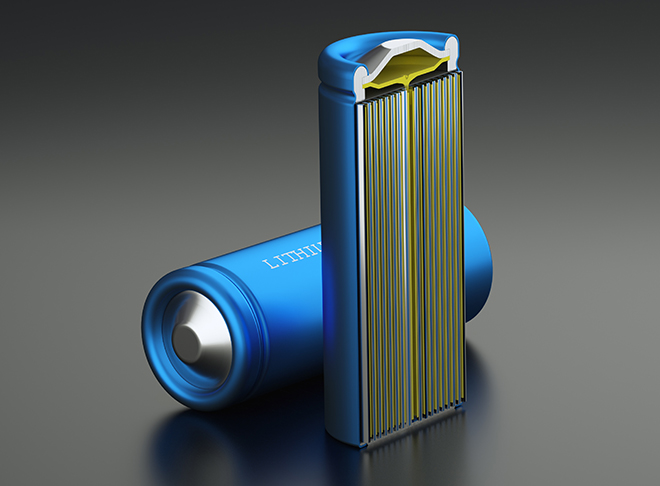

German metal foil specialist SCHLENK has developed a line of thin-rolled metal foils based on high-tensile alloys. Used as a current collector foil in batteries, these foils are designed to improve the stability of battery coatings.

Companies have invested a lot of R&D effort in the field of high-power electrode coatings based on silicon or other additives. This has led to new challenges for anode and cathode foils.

SCHLENK has 90 years of experience in thin foil production – its product line includes metals rolled to thicknesses of 6 to 100 microns, with widths of up to 640 mm. Battery manufacturers are already familiar with SCHLENK’s rolled-annealed (RA) copper anode foil. In order to enhance the stability of current collectors, SCHLENK has improved the mechanical strength by rolling special copper alloys.

In terms of tensile strength, pure copper foils reach a physical limit of around 400 MPa in thin gauges. The electrical conductivity is roughly 98% IACS. Forming a metal alloy by adding other elements to copper, however, changes its properties – tensile strength can be enhanced significantly at the cost of a slight loss of conductivity.

SCHLENK has tested different materials based on copper alloys, rolled to thicknesses of 10 to 20 microns. One alloy showed average tensile strengths of 500 to 600 MPa (70 to 85 ksi) with a conductivity of approximately 86% IACS. The mechanical strength of this alloy is thus 50% higher than that of pure copper.

Going even higher in tensile strength is possible, but reduces conductivity. Tensile strengths of up to 750 MPa can be reached with conductivity of around 40%. Which specific alloy and specification provides a suitable compromise depends on the particular battery application.

In the third quarter of 2019, SCHLENK will add new kit versions with nickel and high-tensile alloy foils. Researchers can test different aspects of metal foils for capacity and cycle behavior in their battery configurations. The pure copper version is currently available, with two thicknesses to choose from: 10 and 18 microns. The width of each roll is 250 mm. SCHLENK’s engineering team is happy to assist customers in choosing the right sample kit.

SCHLENK will present its battery sample kits together with rolled metal foils and tabs at the upcoming Battery Show in Novi, Michigan.

Source: SCHLENK