Rivian Automotive is the brightest rising star in the EV firmament at the moment, and it’s flush with cash following a $11.9 billion stock offering in November. Now the company has announced plans to put some of that nest egg to work at a new $5-billion battery and assembly plant east of Atlanta, which is projected to employ 7,500 workers.

[Superlative alert:] Sources told AP that the headcount at the plant could grow to as many as 10,000, which would make it among the largest auto assembly complexes in the US. The deal is expected to be the largest industrial project in Georgia history, surpassing the 4,400-worker Kia complex that opened in West Point in 2009.

Founder and CEO Robert Scaringe told Bloomberg Television in November that the ability to recruit good workers [read: non-unionized workers] was the most important factor in the decision.

The state of Georgia is believed to have offered rich incentives to Rivian, which reportedly also considered factory sites in Texas, Arizona and Michigan. Georgia’s Mega Project Tax Credit could be worth $118 million in state income tax credits, and local governments may also reduce property taxes.

Rivian, like Tesla, sells directly to customers, and has no plans to build a dealership network. Georgia, like Texas, generally prohibits this sales model. We expect Rivian to work the political levers to try to change this state of affairs (as Tesla has been doing in Texas for years, so far without success).

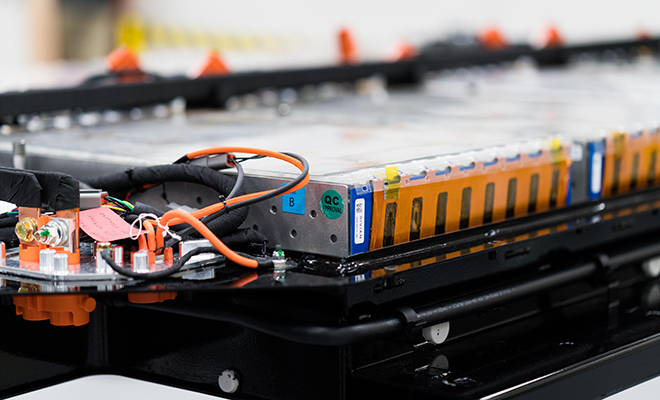

Many foresee surging demand for EVs, and Rivian, which says it has a yearly capacity of 150,000 vehicles at its existing plant in Normal, Illinois, is not the only automaker that’s expanding production capacity. At least one auto analyst is skeptical. “It seems like it might be a little premature to invest that much in another large plant just yet,” said Sam Abuelsamid, Principal Mobility Analyst for Guidehouse Insights, adding that Rivian may also be scouting a site in Europe.

Abuelsamid expects Rivian to make various parts for its vehicles at the new Georgia plant, as Tesla does at its factory in Fremont, California. Tesla has often become frustrated with suppliers’ inability to react quickly enough to its rapidly-evolving needs, and brought production of parts in-house.

With this massive new investment, Rivian has plunged further into the dreaded Valley of Death, and it needs to start bringing in some serious revenue before the massive costs of ramping up production drain its bank account. “If actual deliveries don’t start picking up, the markets could turn against [Rivian] as they have with some other EV startups not called Tesla,” Abuelsamid said. “Rivian will be facing serious competition in a much shorter time frame than the near-decade head start that Tesla had.”

Mr. Abuelsamid is referring to Ford, GM and Tesla, which will be bringing their own electric pickup trucks to market soon.

Source: Associated Press