Yet another exciting advance in battery technology was announced this week. Researchers at Rensselaer Polytechnic Institute, led by nanomaterials expert Nikhil Koratkar, made a sheet of paper from the world’s thinnest material, graphene, then zapped the paper with a laser or camera flash to blemish it with countless cracks, pores, and other imperfections. The result is a graphene anode material that can be charged or discharged 10 times faster than conventional graphite anodes. Results of the study were published this week by the journal ACS Nano.

“Li-ion battery technology is magnificent, but truly hampered by its limited power density and its inability to quickly accept or discharge large amounts of energy. By using our defect-engineered graphene paper in the battery architecture, I think we can help overcome this limitation,” said Koratkar, a Professor of Engineering at Rensselaer. “We believe this discovery is ripe for commercialization, and can make a significant impact on the development of new batteries and electrical systems for electric automobiles and portable electronics applications.”

Graphene is an atom-thick sheet of carbon atoms arranged like a nanoscale chicken-wire fence. In previous studies, Li-ion batteries with graphite anodes exhibited good energy density but low power density, meaning they could not charge or discharge quickly. This was because lithium ions could only enter or exit the battery’s anode from the edges, and slowly work their way across the length of the individual layers of graphene.

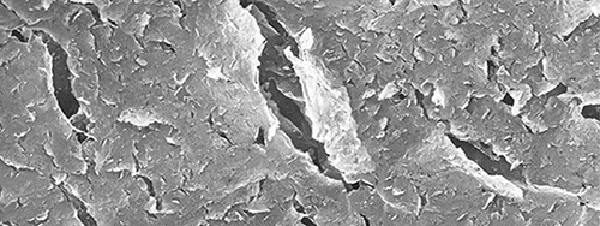

Koratkar’s solution was to create a sheet of graphene oxide paper, about the thickness of a piece of everyday printer paper. The team then exposed some of the graphene paper to a laser, and some to a simple flash from a digital camera. In both instances, the heat caused mini-explosions throughout the paper, leaving sheets of graphene pockmarked with cracks, pores, voids, and other blemishes.

This damaged graphene paper performed remarkably well as an anode for a Li-ion battery. Whereas before the lithium ions slowly traversed the full length of graphene sheets to charge or discharge, the ions now used the cracks and pores as shortcuts to move quickly into or out of the graphene, greatly increasing the battery’s overall power density. The graphene paper anode is remarkably robust, performing successfully even after more than 1,000 charge/discharge cycles.

Koratkar said the process of making these new anodes for Li-ion batteries can easily be scaled up to suit the needs of industry. The next step is to pair the graphene anode material with a high-power cathode material to construct a full battery.

See the paper online here.

Images: ACS, Mukherjee et al.

Sources: Green Car Congress, Rensselaer