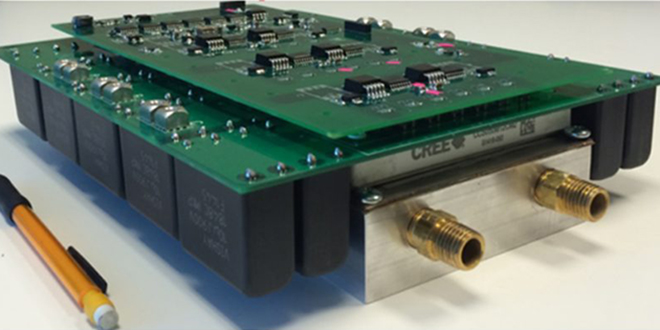

Researchers at North Carolina State University have developed a new type of inverter that offers superior efficiency in a smaller and lighter package than current models.

Conventional inverters rely on components made of silicon. The NC State team has developed an inverter using off-the-shelf components made of the wide-bandgap semiconductor material silicon carbide (SiC).

“Our silicon carbide prototype can transfer 99 percent of energy to the motor, which is about two percent higher than the best silicon-based inverters,” says Professor Iqbal Husain, who co-authored two papers related to the work. “Equally important, the silicon carbide inverters can be smaller and lighter than their silicon counterparts. And new advances we’ve made in components should allow us to make the inverters even smaller.”

The SiC-based inverter can convey 12.1 kilowatts of power per liter (kW/L) – close to the DOE’s goal of developing inverters that can achieve 13.4 kW/L by 2020. By comparison, a typical 2010 EV could achieve only 4.1 kW/L.

“Conventional silicon-based inverters have likely improved since 2010, but they’re still nowhere near 12.1 kW/L,” Husain says.

“We are pretty sure that we can improve further on the energy density that we’ve shown with this prototype,” Husain says.

That’s because the prototype was made using off-the-shelf SiC components, but the researchers have recently made new and better components, and improved heat dissipation.

“We predict that we’ll be able to make an air-cooled inverter up to 35 kW using the new module, for use in motorcycles, hybrid vehicles and scooters,” Husain says. “And it will boost energy density even when used with liquid cooling systems in more powerful vehicles.”

A paper on the new inverter, and another on the new SiC power component, will be presented at this month’s IEEE Energy Conversion Congress and Exposition (ECCE) in Milwaukee.

Source: North Carolina State University

Photo courtesy of Iqbal Husain