The big buzz on the EV tech scene these days is about silicon anodes, which could offer ten times more storage capacity than carbon anodes. Scientists around the world are looking for ways to overcome the remaining obstacles to using silicon for a new generation of lithium-ion batteries.

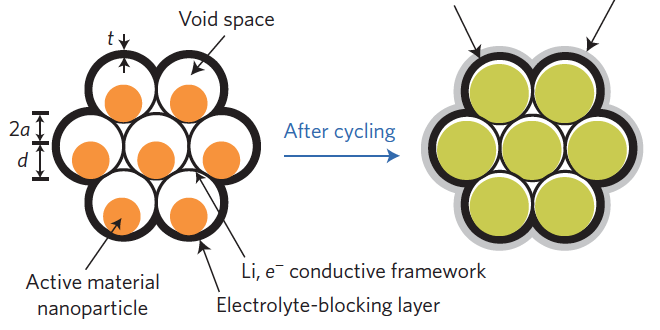

Researchers at Stanford University and the DOE’s SLAC National Accelerator Laboratory think they are on the track of a solution – an electrode designed like a pomegranate, with silicon nanoparticles clustered like seeds in a tough carbon rind.

“While a couple of challenges remain, this design brings us closer to using silicon anodes in smaller, lighter and more powerful batteries,” said lead researcher Yi Cui. “Experiments showed our pomegranate-inspired anode operates at 97 percent capacity even after 1,000 cycles of charging and discharging, which puts it well within the desired range for commercial operation.”

Over the past eight years, Cui’s team has been using silicon nanowires or nanoparticles encased in carbon “yolk shells” that give them room to swell and shrink during charging. The new study, recently published in Nature Nanotechnology, builds on that work.

The team used a microemulsion technique common in the oil, paint and cosmetic industries to gather silicon yolk shells into clusters, and coated each cluster with a second, thicker layer of carbon. These carbon rinds hold the pomegranate clusters together and provide a sturdy highway for electrical currents.

And since each pomegranate cluster has just one-tenth the surface area of the individual particles inside it, a much smaller area is exposed to the electrolyte, thereby reducing deposits to a manageable level.

Although the clusters are too small to see individually, together they form a fine black powder that can be used to coat a piece of foil and form an anode. Lab tests showed that pomegranate anodes worked well when made in the thickness required for commercial battery performance.

While these experiments show the technique works, Cui said, the team will have to solve two more problems to make it viable on a commercial scale: They need to simplify the process and find a cheaper source of silicon nanoparticles. One possible source is rice husks, a waste product that could be transformed into pure silicon nanoparticles, as his team recently described in Scientific Reports.

Source: Nature Nanotechnology (2014) via Green Car Congress

Image: Liu et al. / Nature Nanotechnology (2014)