The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University is working with industrial partners on the Kreislauf.IN.NRW battery cell recycling research project.

The project, funded by the Ministry for the Environment, Nature Conservation and Transport of the State of North Rhine-Westphalia, aims to investigate the production and functionality of cells containing more than 80% recycled material. The companies participating from the industry are NEUMAN & ESSER, Accurec Recycling, Iondrive EU, and Constantia Patz.

“Recyclable components of lithium-ion battery cells have so far only been considered individually and have not been tested for their actual interaction in new batteries,” said Professor Achim Kampker, head of the PEM research group.

“The global battery industry already uses recycled metal salts such as nickel and cobalt sulfate or lithium hydroxide in some cases, but the precise behavior of the materials in the battery cell—for example, aging, safety, and the necessary purity—is not fully understood,” added Professor Heiner Heimes, a member of the PEM management team.

However, the reintroduction of these materials into battery production is considered essential to comply with the requirements of the EU Battery Regulation regarding minimum recycling quotas for cathode active materials.

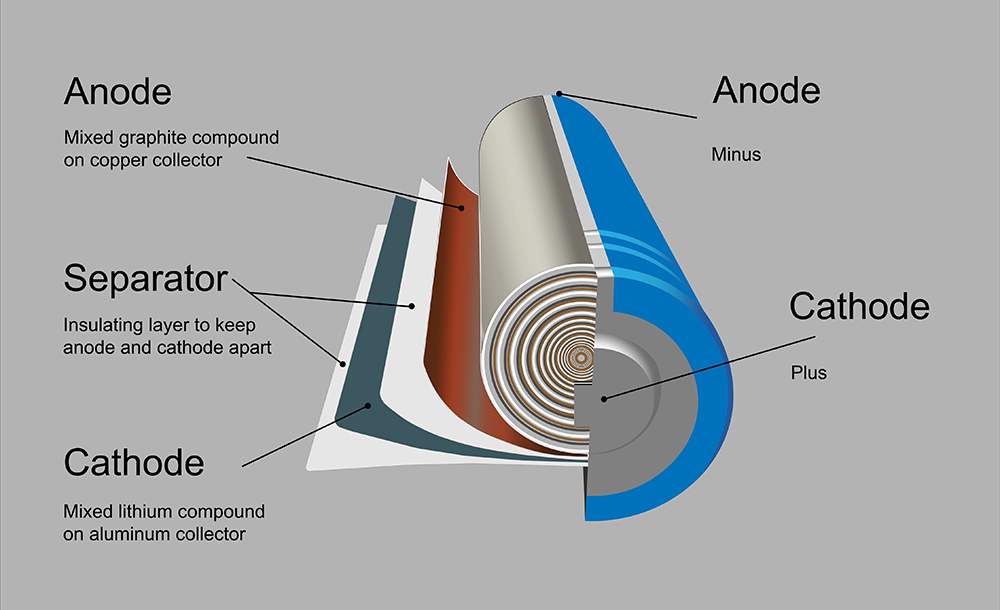

In particular, the use of graphite anode material from secondary sources has so far proven unattractive because of a deterioration in the morphology of the active material at the end of its life, increased contamination such as by binders, and technological and economic challenges. The processing of recyclable graphite is considered costly compared to using primary material.

Other battery components, such as the aluminum and copper conductive foils, the separator, and the electrolyte, also present challenges for recycling and reuse. The focus is currently on the active materials, as they comprise 70% percent of the battery. But the recycling of inactive components will also be needed to achieve the principle of the circular economy.

“While recycling most battery components is now technically possible, no battery cell has yet been manufactured that contains at least 80 percent recycled material,” Kampker said.

The Kreislauf.IN.NRW project aims to achieve this and develop a scalable process.

Source: RWTH Aachen University