Oxfordshire-based Oxis Energy has been working on lithium-sulfur battery technology since 2004 (Charged has reported on the company several times over the years). In a recent article in IEEE Spectrum, the company’s Head of Battery Development and Integration, Mark Crittenden, explains why lithium-sulfur tech is uniquely suited to electric aviation.

Weight is a critical constraint for aircraft (and for other types of vehicles, such as long-haul trucks), and the limited specific energy (aka gravimetric energy density) of current lithium-ion batteries imposes strict limits on the size, payload and range of a battery-electric aircraft. Mr. Crittenden, for one, doubts that a large long-haul airliner using Li-ion batteries would be practical at all.

Lithium-sulfur batteries are theoretically far lighter. Current lithium-ion designs achieve specific energy of 100 to 265 Wh/kg. Oxis says it has a prototype lithium-sulfur pouch cell that offers 470 Wh/kg. The company expects to boost that to 500 Wh/kg within a year, and hopes to reach as much as 600 Wh/kg by 2025.

Oxis packages the cathode, anode, separator and electrolyte into pouch cells, which are connected both in series and in parallel to form a 20-amp-hour, 2.15-volt battery pack. For an airplane, scores of packs are connected to provide a capacity of tens or hundreds of amp-hours at several hundred volts.

Lithium-sulfur batteries go through multiple stages as they discharge, each time forming a distinct molecular species of lithium and sulfur. When a cell discharges, lithium ions in the electrolyte migrate to the cathode, where they combine with sulfur and electrons to form a polysulfide, Li2S8. During charging, electrons flow in the opposite direction, causing the cathode to give up electrons, converting Li2S to Li2S2. The polysulfide continues to add sulfur atoms until Li2S8 is formed in the cathode. Each time electrons are given up, lithium ions diffuse through the electrolyte, combining with electrons at the lithium electrode to form lithium metal.

Over many charge and discharge cycles, side reactions cause degradation. Crittenden explains that minimizing these reactions, through the selection of the appropriate materials and cell configuration, is the underlying challenge that must be met in order to produce an efficient lithium-sulfur cell with a long life span.

Degradation of the lithium-metal anode is also a problem. However, unlike lithium-ion cells, this degradation does not involve the formation of dendrites. In lithium-sulfur cells, uneven current densities on the anode surface cause lithium to be plated and stripped unevenly, which eventually causes moss-like deposits, leaving less of the anode surface available for chemical reaction. To solve this degradation problem, Oxis is pursuing a promising strategy that involves coating the lithium-metal anode with thin layers of ceramic materials.

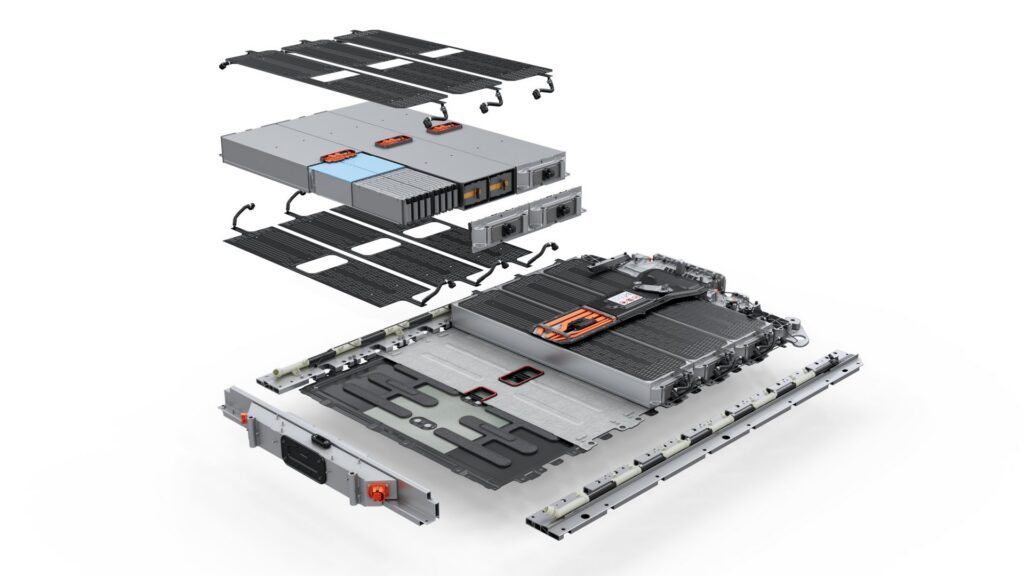

Regardless of the battery chemistry, a dedicated thermal-management system is de rigueur. Whereas liquid cooling is the preferred technology for cars, in aviation, air cooling is preferred because it adds less weight. Oxis is using computational modeling to explore cooling systems that rely on a battery pack’s positioning within an aircraft—for example, placing batteries within a wing, where air is naturally moving across the surface, or shunting air to the battery through ducts.

Oxis is collaborating with several electric aircraft makers, including Colorado-based Bye Aerospace, which has conducted flight trials of its eFlyer 2-seater plane.

Oxis is also developing two manufacturing projects: a plant for the production of electrolyte the cathode active materials in Port Talbot, Wales; and a site in Minas Gerais, Brazil that will be used for mass production of lithium-sulfur cells. Oxis hopes to have its production facility in operation by 2023.

Source: IEEE Spectrum