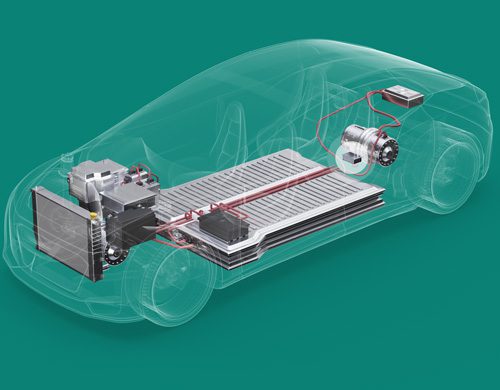

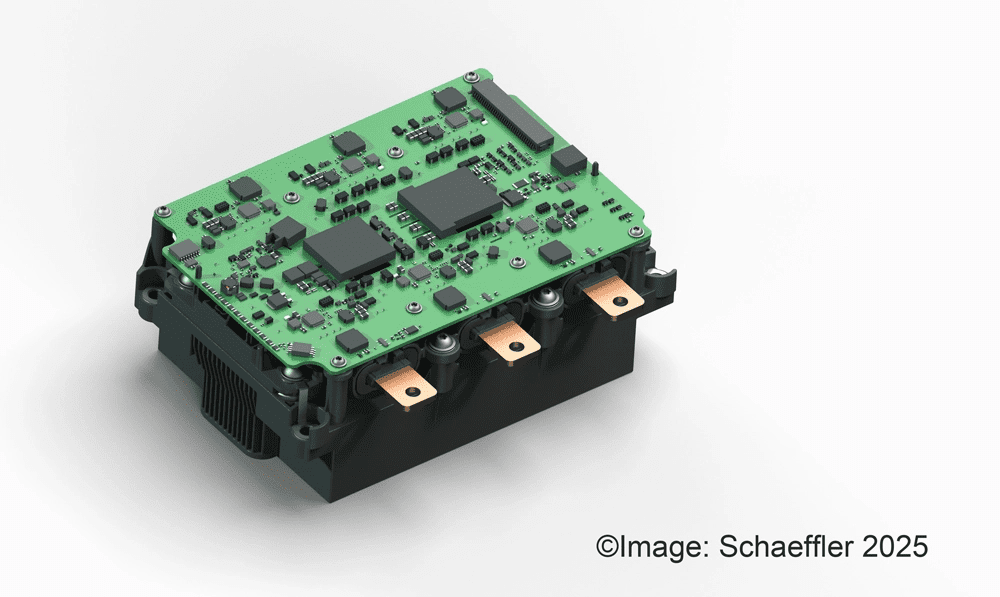

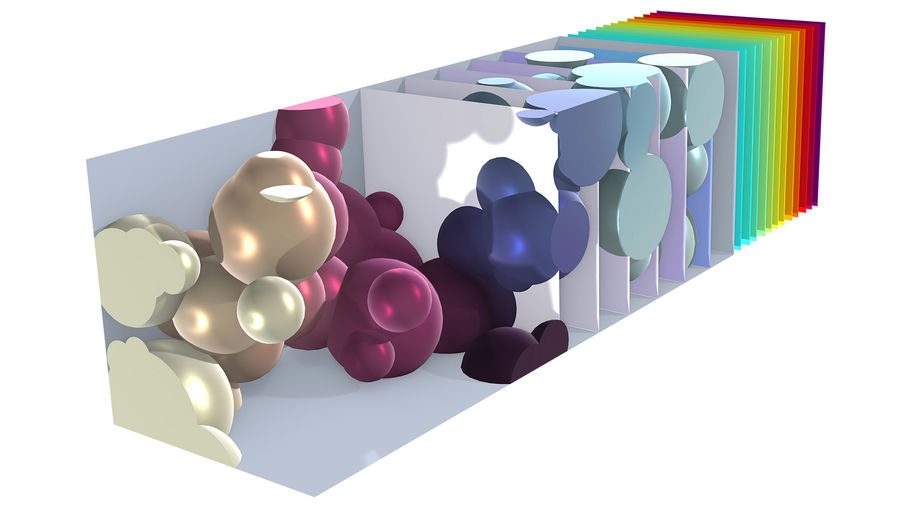

onsemi has expanded its collaboration with Schaeffler to supply silicon carbide (SiC) MOSFETs from its next-generation EliteSiC product line for a new plug-in hybrid electric vehicle platform. The traction inverter, developed by Schaeffler for a global automaker, uses onsemi’s SiC technology to improve energy efficiency, reliability, and packaging flexibility.

According to onsemi, the EliteSiC MOSFETs offer the lowest on-state resistance in their class, enabling higher peak power delivery and system efficiency. The devices provide low conduction losses and strong short-circuit robustness, allowing for a compact and thermally efficient inverter design. These characteristics help extend vehicle range, reduce maintenance, and support more flexible vehicle integration.

“The traction inverter is at the heart of every electrified drivetrain, and onsemi’s EliteSiC solution plays a vital role in achieving the efficiency and performance targets that our customer demands,” said Christopher Breitsameter, Head of Business Division Controls at Schaeffler.

The partnership marks a shift from insulated-gate bipolar transistors (IGBTs) to SiC in hybrid platforms, even for cost-sensitive EV architectures.

“Our industry-leading silicon carbide semiconductor technology delivers unmatched efficiency, thermal performance, and power density—key enablers for next-generation electric powertrain systems not only for battery electric vehicles, but also for plug-in hybrid platforms,” said Simon Keeton, Group President of the Power Solutions Group at onsemi.

This announcement builds on a multi-year collaboration between the two companies—formerly under Vitesco Technologies, which merged with Schaeffler in 2024—to develop high-efficiency electric mobility solutions.

Source: onsemi