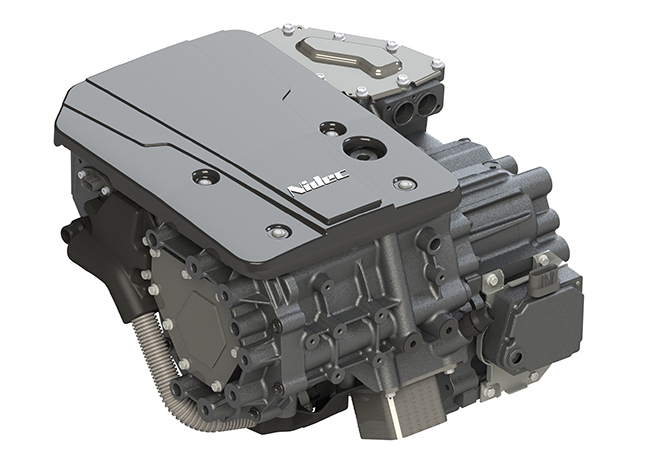

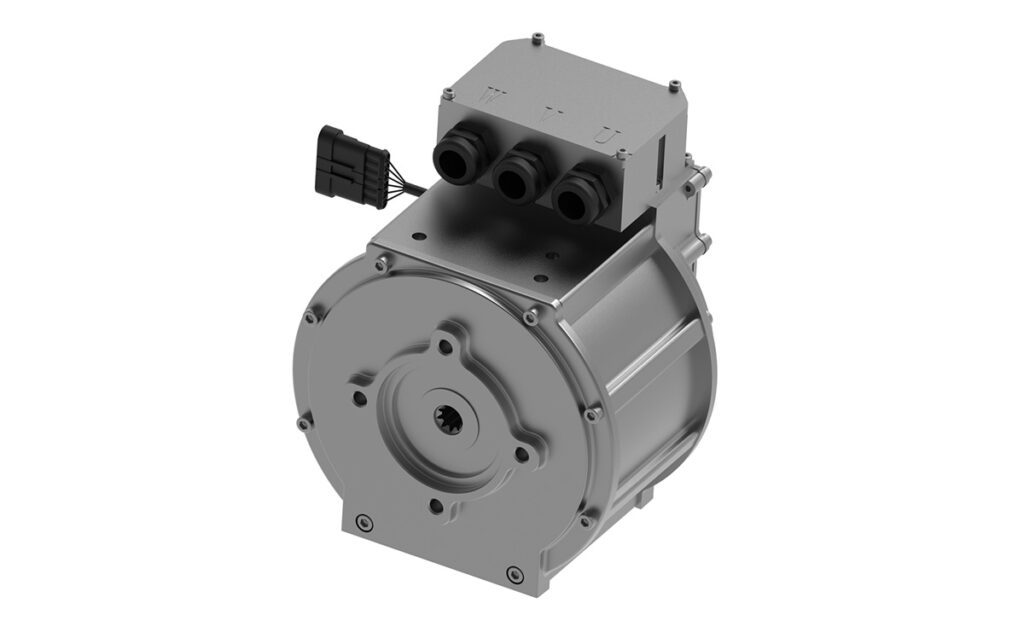

Nidec, which was founded in 1973 as a Japanese manufacturer of small electric motors, and now employs some 100,000 people in 40 countries, has developed an integrated traction motor system called the E-Axle.

Nidec’s E-Axle fully integrates the reduction gearbox and inverter. Designed to be compact and lightweight, it weighs only 83 kg, and offers a power output of 150 kW and maximum torque of 3,900 Nm.

Now Nidec has announced that its E-Axle will be used in a line of cars called Aion S from the new Chinese EV brand GAC NE, the new energy vehicle arm of Guangzhou Automobile Group. The Aion S, unveiled at the recent Auto Guangzhou show, boasts a range of over 500 kilometers (311 miles), and is slated to hit the market in 2019.

Nidec plans to begin mass production of the E-Axle in 2019 at the company’s new dedicated 66,000-square-meter factory in the Pinghu Economic Development Zone near Shanghai.

Although Nidec will launch the E-Axle in the Chinese market first, it plans to make it available to European auto brands in the near future. “Carmakers from all around the world have contacted us since we announced our E-Axle and we are currently considering building another dedicated factory in Poland,” said Dr. Kazuya Hayafune, Chief Engineer and Deputy Executive General Manager of the company’s automotive division.

Nidec also recently launched a joint venture with Groupe PSA (Peugeot, Citroën, Opel and Vauxhall) to develop and manufacture a separate lineup of automotive electric traction motors.

Source: Nidec