NI, formerly National Instruments, has announced two new projects for EV traction inverter validation: a new Inverter Test System (ITS) and a collaboration agreement with D&V Electronics for power-level inverter testing.

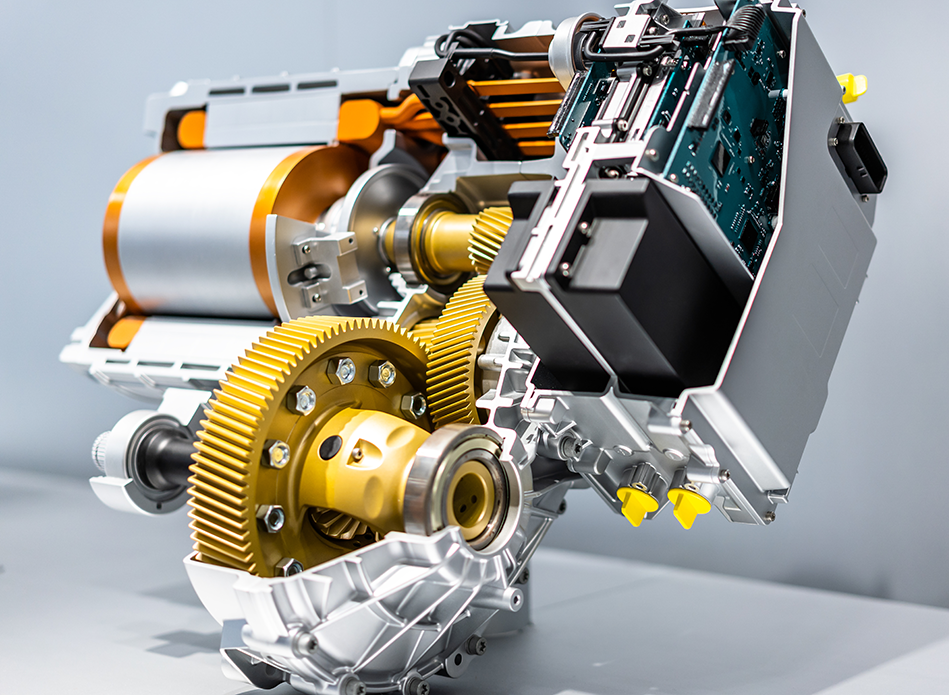

Both projects are designed to accelerate innovation for EVs by integrating tests earlier in the product development lifecycle. By simulating EV powertrains to perform hardware-in-the-loop tests of inverter electronic control units (ECU), the ITS allows test engineers to create more life-like scenarios that are not easy to reproduce accurately on the road.

Electric motors and DC power emulators can be inserted into the test workflow to enable durability and thermal testing of the inverter component at full power in a safe environment. Adding more simulation fidelity and capabilities speeds up the entire development process at a lower overall cost than field tests.

“Automotive engineers are constantly modifying simulation models based on evolving electric vehicle performance and test requirements,” said Noah Reding, Director at NI. “Advancements such as these speed up EV adoption and production innovations by eliminating inefficiencies in the testing process.”

“Traction inverters are the heart of the powertrain, and inverter design technology is changing rapidly,” said Uday Deshpande, CTO of D&V Electronics. “D&Vs innovative power emulators, combined with NI’s high-speed test platforms, will offer customers future-ready capabilities that enable coverage from component- to system-level testing in a controlled environment.”

Source: NI