Dutch firm RGS has introduced a nano-porous silicon material called E-magy that’s designed to be used in the anodes of Li-ion batteries. The company claims its material can increase battery anode capacity by up to 50%.

Battery boffins have long dreamed of replacing carbon material in anodes with silicon, but in practice the amount of silicon used has been limited, as the material tends to swell during charging, limiting battery life.

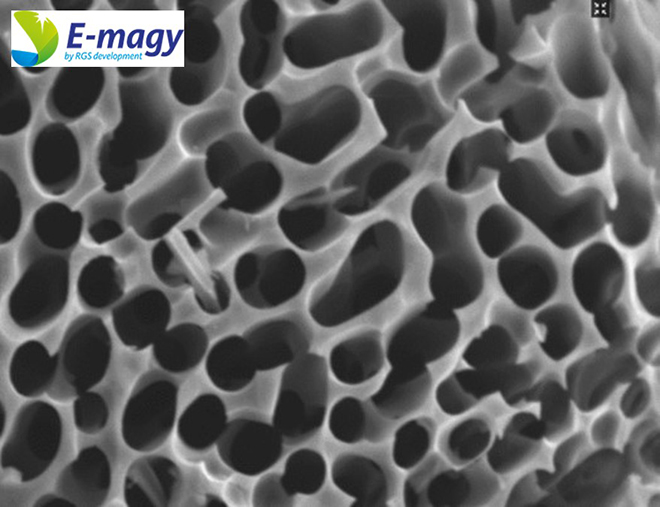

RGS’s E-magy nano-porous silicon material is designed to absorb lithium ions during battery cycling the way a sponge absorbs water. According to the company, this prevents outside swelling of the battery anode, while increasing capacity by a factor of three or more.

E-magy will be supplied as a powder, and can be used in existing supply chains and battery factory production processes to gradually enhance battery capacity. RGS manufactures the silicon material using a patented rapid casting technology.

“RGS has achieved a process for scaling up micro-sized silicon particles with a nano-structured morphology,” says Dr. Erik Kelder, an Associate Professor at Delft University. “This combination of structures prevents many obstacles and safety issues encountered with micron- or nano-sized silicon alone, and will maintain its quality during charging and discharging.”

RGS recently started manufacturing E-magy silicon, and it is now available for customer qualification. E-magy is intended to be mixed into a carbon anode at desired amounts according to customer-specific formulations.

RGS is preparing to expand its industrial facility to to a production capacity of 50 tons per year, which represents one GWh of battery manufacturing capacity.

“We believe that our E-magy product, founded deeply in our silicon technology experience, will be instrumental to large-scale manufacturing initiatives for battery systems,” says Dr. Axel Schönecker, CTO of RGS. “This will benefit e-mobility, electronics and large utility storage battery applications.”

Source: RGS development