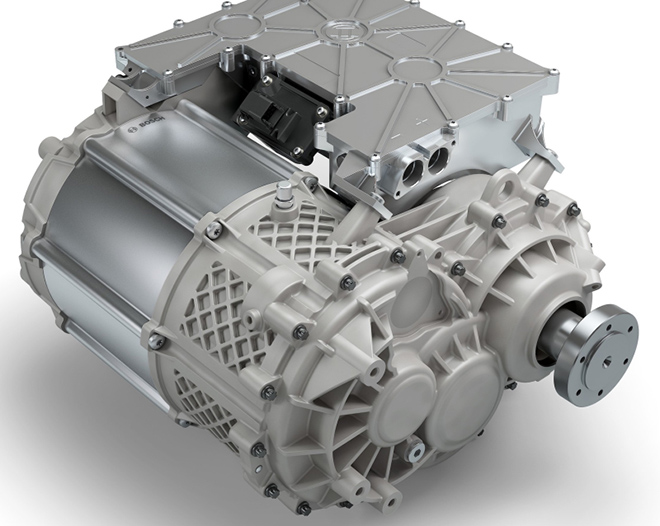

Bosch has developed a new electric axle drive, or e-axle, that integrates the motor, power electronics, and transmission into one compact unit that directly drives a vehicle’s axle, saving both space and costs. An electric axle delivering 150 kilowatts weighs roughly 90 kg – far less than currently available individual components.

Bosch has had electric axle drives on the market since 2012 (used in the Peugeot 3008 and Fiat 500e), but this is the first model to fully integrate the power electronics. Samples of the new e-axle are currently being tested, and production is planned for 2019 at the latest.

The e-axle can be adapted to many types of hybrids and EVs, from compact cars to SUVs to light trucks, and can be used in front- or rear-axle drive configurations. The powertrain can deliver between 50 and 300 kW, so it’s capable of powering even large vehicles such as SUVs completely electrically. Torque can range from 1,000 to 6,000 N·m.

Bosch can create a custom-designed powertrain that an OEM can quickly integrate into its manufacturing operations. All the customer has to do is state the performance, torque, and installation space required – Bosch will optimize the powertrain to fit these parameters, and deliver a customized e-axle to an automaker’s assembly line.

Source: Bosch via Green Car Congress