Canada’s Innovation, Science and Economic Development program plans to invest up to $1.9 million in Vancouver-based Nano One, which currently produces energy storage materials and a range of nanostructured composite materials.

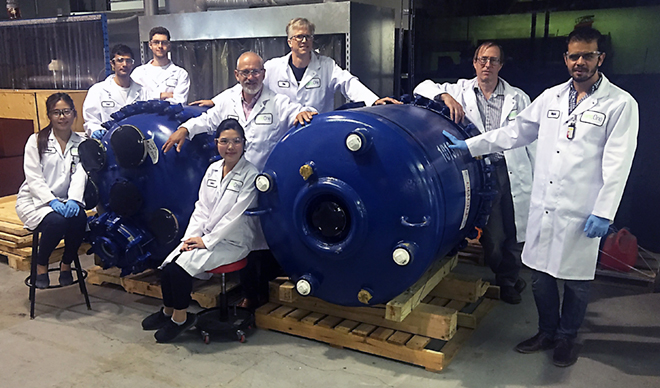

The funding will support a pilot plant that will simulate full-scale production of lithium-ion cathode materials and showcase Nano One’s processing technology.

Some promising cathode materials currently being developed depend on processes with 50 to 100 steps and production cycles of 4-7 days. Nano One says its technology can use lower-grade raw materials and complete a production cycle in less than a day. There is less handling, lower capital costs, no waste solvents and fewer failure points.

As a result, Nano One hopes to reduce per-kWh costs by up to 50%, as well as delivering robustly structured cathode materials that last longer, store more energy and deliver more power.

The pilot uses common industry equipment and is designed to be flexible enough to demonstrate a variety of processing concepts and chemistries, enabling Nano One to adapt to market needs and produce a range of cathode materials, including lithium nickel manganese cobalt oxide, high-voltage spinel and lithium iron phosphate.

The innovations lie in a three-stage aqueous process that enables a wider range of raw material inputs, eliminates manufacturing steps and provides high-purity, high-performance materials.

“The support leverages existing plans to build and operate our Demonstration Pilot Plant,” said Nano One CEO Dan Blondal. “We remain on target to have the pilot built early in 2017, and our approach is already drawing the attention of multinational lithium-ion battery stakeholders in the automotive supply chain.”

Source: Nano One via Green Car Congress