Meta Materials has signed a memorandum of understanding) with DuPont Teijin Films and Mitsubishi Electric Europe. Using Meta’s PLASMAfusion coating technology, the parties plan to scale a proprietary, high-volume, roll-to-roll manufacturing system for film-based, coated copper current collectors. The film-based products are expected to reduce battery weight and cost, improve energy efficiency, extend vehicle range, and reduce the risk of thermal runaway.

Meta will provide the PLASMAfusion technology platform, DuPont will develop and supply the polyester substrates, and Mitsubishi will contribute automation technology, and interface with machine builders.

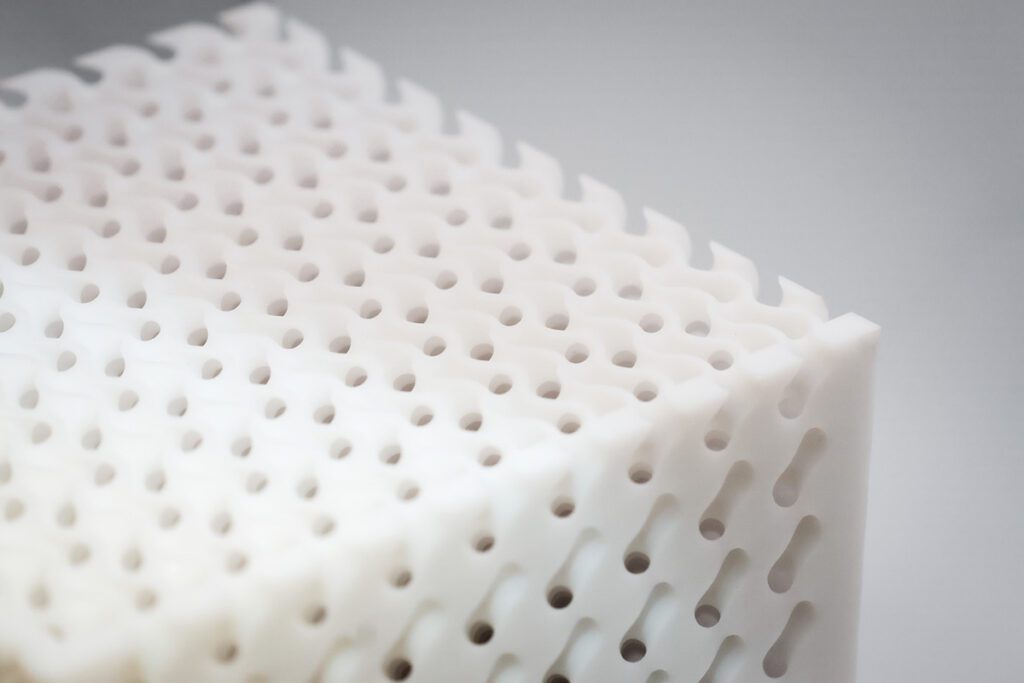

Meta’s PLASMAfusion technology involves depositing thin layers of copper on both sides of a polyester substrate, which the company says reduces the weight of the current collector by up to 80%. Lighter weight increases energy density, and the polyester inner layer acts like a fuse, helping to prevent thermal runaway. The company says this technology can reduce dependence on copper, which is expected to be in short supply in the future.

Current collectors used on the cathode and anode are made from aluminum and copper foils, respectively, and together contribute about 15% of the weight of the battery cell; the heavier copper material accounts for more than 10%.

“Current Li-ion battery innovations focus mainly on extending battery range and life span. With the increased demand for electric vehicles, a next-generation Li-ion battery is required that is more sustainable and safer,” said George Palikaras, META’s President and CEO.

Source: Meta Materials