Mercedes-Benz has unveiled plans to expand its global battery recycling strategy. The automaker will build its own battery recycling plant in Kuppenheim, Germany, and plans to enlist partners for battery recycling in China and the US.

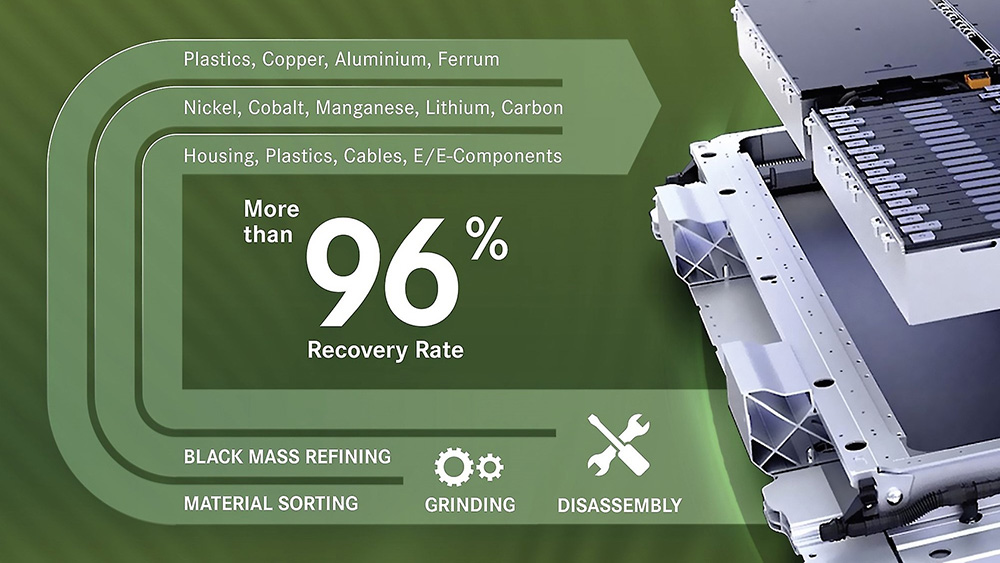

“Mercedes-Benz is pursuing a maximum circular economy for all raw materials used,” said Board Member Jörg Burzer. “Sustainable battery recycling is a key factor in this, worldwide. With our new recycling plant at the Kuppenheim location, we are increasing the recycling rate to more than 96 percent while expanding our own expertise in the area of battery value creation. Through targeted collaborative ventures with high-tech partners in China and the US, we are globalizing our battery recycling strategy and taking a decisive step toward closing the recycling loop in e-mobility.”

Mercedes will establish a pilot plant for the recycling of lithium-ion battery systems, under a new wholly-owned subsidiary called LICULAR. For the design and construction of the facilities, LICULAR will cooperate with Primobius, a joint venture of the German mechanical engineering company SMS group and the Australian project developer Neometals. Scientific support for the project will be provided by the Karlsruhe Institute of Technology and the Technical Universities of Clausthal and Berlin.

The project will use a patented hydrometallurgy process that Mercedes says “completely dispenses with energy-intensive and material-consuming pyrometallurgical process steps,” and can achieve recovery rates of more than 96 percent. The process recovers battery-grade cobalt, nickel and lithium, and is expected to be able to recover graphite in the future. Mercedes estimates that recycling these materials will deliver a CO2 savings of up to 70% per battery.

The pilot plant is expected to have an annual capacity of 2,500 tons. The recovered materials will be fed back into the recycling loop to produce more than 50,000 battery modules for new Mercedes-EQ models.

Mercedes will invest “a double-digit million-euro amount” in construction and R&D at the plant. Construction will take place in two stages. A plant for mechanical dismantling will be constructed by 2023, following which the facilities for hydrometallurgical processing of the battery materials will go into operation. In the future, the Kuppenheim facility could cover all stages of recycling, from dismantling to module level shredding and drying and subsequent processing of battery-grade material flows.

“The pilot factory at the Kuppenheim location marks the Mercedes-Benz Group’s entry into the important field of battery recycling, and will make the company more independent of raw material supplies in the future,” said Michael Brecht, Chairman of the Works Council at Kuppenheim. “At the same time, we are gathering important know-how on the subject of the circular economy and creating new, sustainable jobs that can be further expanded if operations are successful.”

Source: Mercedes-Benz