US-based chemical manufacturer Lyten has started shipping lithium-sulfur A sample cells to its investor Stellantis and other US and EU automotive OEMs for evaluation.

The company has also started shipping samples to a major consumer electronics company and to US military agencies. It is targeting delivery of samples to more than 20 potential customers during the second and third quarters of this year.

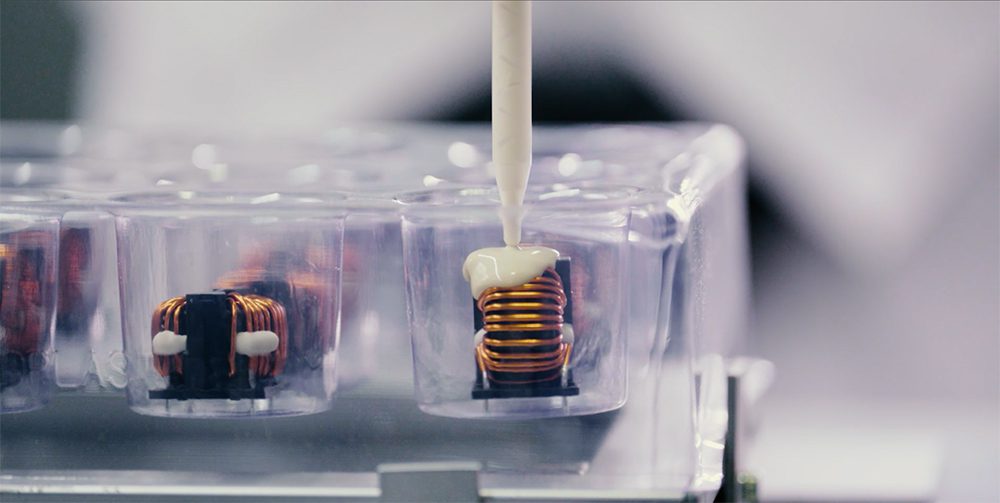

The battery samples are being manufactured on Lyten’s semi-automated pilot line in San Jose, California, which opened in May 2023. The pilot line was built using standard lithium-ion equipment and manufacturing practices, indicating that manufacturers can switch their existing facilities to lithium-sulfur production. The line is capable of delivering A and B samples for automotive OEMs and fully commercial cells for small-volume customers. Lyten is designing its first gigawatt-scale facility with Turner Construction and SSOE to manufacture automotive C samples and beyond.

Lyten manufactures lithium-sulfur cells in pouch and cylindrical formats (2170 and 18650) and is currently shipping the 6.5 Ah pouch cell format—which has a 3 C discharge rate at 25° C—for customer evaluation. The company plans to deliver cylindrical A samples for evaluation later this year.

Lithium-sulfur battery technology has the potential to deliver twice the energy density of nickel manganese cobalt (NMC) batteries, while competing on cost with lithium iron phosphate (LFP), according to Lyten. Removing the need for nickel, manganese, cobalt and graphite means a projected carbon footprint at least 65% lower than that of lithium-ion batteries and a supply chain that can be fully sourced in the US or EU at scale.

“The world needs a practical, mass-market battery, and that is what we are building with our lithium-sulfur technology,” stated Celina Mikolajczak, Chief Battery Technology Officer at Lyten. “Mass market electrification and net zero goals demand higher energy density, lighter and lower-cost batteries that can be fully sourced and manufactured at massive scale using abundantly available local materials.”

Source: Lyten