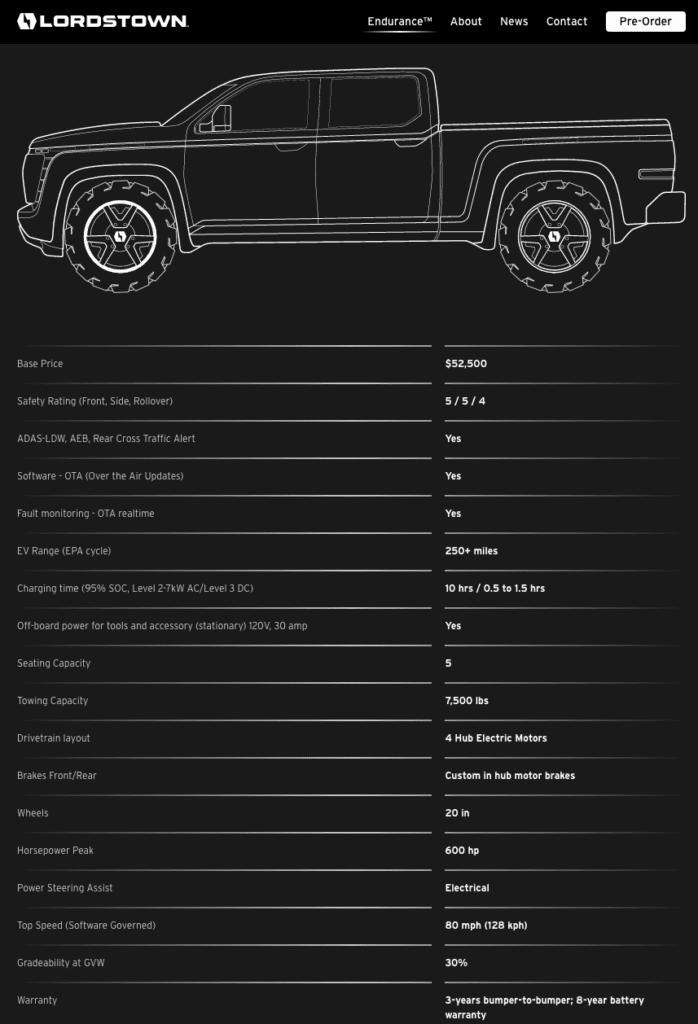

Lordstown Motors, the startup headed by Workhorse CEO Steve Burns, is building an electric pickup called the Endurance at a former GM factory in Lordstown, Ohio. The Endurance is expected to be available in the fourth quarter of 2020 at a base price of $52,500.

The new e-pickup will feature in-wheel hub electric motors, according to specs published on the Lordstown’s website. Mounting motors inside the wheel hubs frees up space, and enables different amounts of torque to be delivered to each wheel with precise electronic controls, rather than by using a more traditional hardware solution such as a differential.

Several suppliers, including Elaphe, Protean and Nidec, have developed in-wheel motors. Aptera, a startup that’s building an ultra-efficient EV, says Elaphe’s in-wheel motors offer advantages including enhanced aerodynamics, lower vehicle weight and low energy usage.

Others are skeptical. The classic objection to in-wheel motors is their additional unsprung mass, which makes it more challenging to achieve a smooth ride and handling.

Croatian supercar builder Rimac uses a 4-motor design, but these are not in-wheel hub motors. “In-wheel hub motors add unsprung mass that results in higher stress to suspension components,” founder Mate Rimac told Charged in 2016. “Our motors sit low and inboard, close to the center of the car, which we consider to be better for vehicle dynamics.”

In a 2018 interview, Lucid’s Peter Rawlinson told Charged, “There is that unsprung mass issue, which degrades ride, but that’s not the key thing: it’s getting that…suspension geometry, particularly upfront with the steering geometry, and also getting conventional foundation brake cooling, those are the real killer issues.”

Mobility futurist James Carter made some particularly scathing comments about in-wheel motors in a LinkedIn post: “For some small efficiency gains (all the advantages mentioned in [a Motor Authority article] also apply to body-mounted 4-motor systems like Rivian), the Lordstown will have the strong possibility of worst-in-class ride and handling due to high unsprung mass. Not only that, powertrain unreliability is highly probable from mounting the motor and electrical components on a constantly moving platform that is exposed to high shocks and forces.”

Source: Lordstown Motors via Motor Authority