The legacy automakers are slowly and methodically developing new EVs, with various levels of enthusiasm, but the most ambitious plans for new vehicles are coming from a handful of EV startups. Most of these pioneers of the new auto industry share a formula: deep-pocketed investors (many from China), former Tesla employees on staff, and plans to emulate Tesla’s strategy of starting with a high-priced, low-volume vehicle as a stepping stone to a more mass-market model.

There are several reasons to call Lucid Motors the most promising of this crop of companies. First, Lucid has been around for over a decade. Founded as Atieva in 2007 by former Tesla VP Bernard Tse and others, the company initially focused on battery packs, but in 2014 it decided to take up the quest of building its own EV.

Another reason to take Lucid seriously is provided by the impressive prototypes it has built. In 2016, the company revealed a delivery van that can do 0-60 in just over three seconds. “Edna,” a converted Mercedes Metris van, made her debut with a video of a drag race versus a Ferrari and a Model S – both of which she beat. Atieva used Edna as a test vehicle for its powertrain technology.

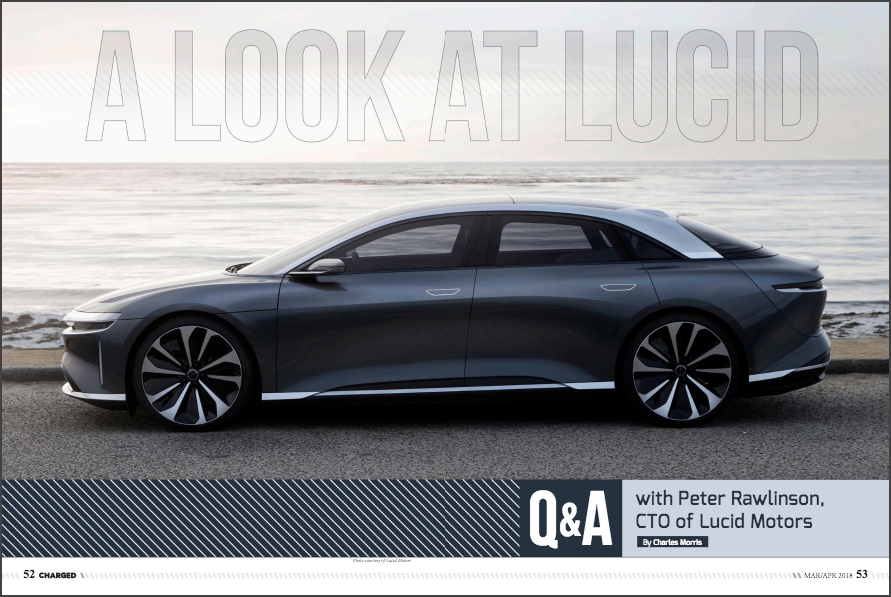

Later in 2016, the company renamed itself Lucid, and released some teaser images of an electric luxury sedan. A few copies of that vehicle, the Lucid Air, are now tooling around the roads of California. Bloomberg got a ride in a rough prototype in March of 2017. A much more polished version was on display at the Los Angeles Auto Show in December – Wired took a test ride and called it “stunning.”

Lucid’s ace in the hole is the impressive pedigree of its vehicle design team. CTO Peter Rawlinson is not just any Tesla alum – after stints at Jaguar, Lotus and Corus Automotive, the Welsh-born Rawlinson became the Chief Engineer behind Tesla’s Model S.

The company has a lot of other proven EV talent on staff. “I have the key brain power behind the Model S team with me today,” says Rawlinson. “We know how to do this, and that is the differentiator [between us and other EV startups].”

Lucid is building a factory in Casa Grande, Arizona, and plans to play it slow and steady, starting off at a production rate of 20,000 cars per year, which it calculates will require $260 million in investment. “We’re taking a very pragmatic, almost humble approach to it,” Rawlinson told Wired. “We’re not going in there all guns blazing, saying we’re going to spend a billion dollars on a factory. That’s madness.”

Charged was fortunate enough to have a chat with Peter Rawlinson. He’s a highly articulate speaker who does a great job of explaining his company’s unique vision, so we thought it best to present his comments in his own words, lightly edited for clarity and brevity.

Charged: We’ll make our first question about batteries. What kind of cells are you using?

Peter Rawlinson: We’ve sourced Samsung SDI for cylindrical cells. We’ve also got a production contract in place with LG Chem, but our primary production source is Samsung SDI.

Charged: Are these standard 2170 cells?

Peter Rawlinson: They’re standard in terms of their size and form factor, but they’ve been co-developed in terms of their chemistry to combine great energy capacity with a tolerance for cyclic fast charging. Some of the leading players out there have a cell chemistry which is particularly vulnerable to repeated cyclic fast charging, and that actually accelerates the degradation of the battery pack in terms of its ability to store energy quite dramatically over the course of maybe a couple of hundred fast charge cycles.

The best analogy I can make is that of a decathlete – we’re not just out for sprint or hurdles or a discus throw or a long jump, we’re looking at a rounded capability within the cell. Some of the key attributes we look for are power, energy, lifetime, cold-weather capability, storage when being unused (a lot of the degradation takes place during that, actually), and tolerance to fast charging.

Charged: Why did you make fast charging a top priority?

Peter Rawlinson: We see the likelihood of more intense use patterns for electric cars in the future. If you look at China, which would be a big market for us, the typical Chinese owner hasn’t got the ability to readily install an overnight slow charging station in their garage as a typical US owner would. Therefore, they’re more dependent in China upon stop-and-go fast charging, like the way we use gas stations at the moment in the Western world.

Also for when we see more intensive ride-share applications, we think having tolerance to repeated fast charging, combined with great energy capacity, is the way to go. If you look at the way mobility is going to move, it’s going to move towards a shared mobility. We’re already seeing that with ride-sharing and with services such as Uber Black, even for high-end vehicles.

Lucid Air is autonomous-ready in terms of its hardware and sensor suite and whole system integration – ready for when appropriate software and legislative conditions allow. We’ll move to the autonomous driving era, we’ll move to this era of shared autonomy, and that will see much more intense use patterns. The electric car is particularly suited to that paradigm. We’ll have a situation where, unlike today where I use my car for about an hour a day, and 23 hours of that day it’s sitting out there gathering dust and depreciating, we’re going to see a much more intense use of the cars that are available. I think that’s going to be hugely beneficial for all people, particularly those who live in a densely populated urban environment.

Charged: What can you tell me about the battery packs?

Peter Rawlinson: We’re water/glycol liquid-cooled and we have our patented cooling system, which I really believe is a big advance over any competitor that’s out there at the moment. I believe that is really central to our battery technology. We started off 10 years ago as a battery technology company. We have a decade of expertise in this area and we have about 20 million miles accrued now in real-world use with our battery packs.

All the battery pack is designed in-house, and we have a wealth of patents. As a company we have around 300 patents now, and a large part of that is our powertrain and particularly the battery pack. We’re able to achieve extraordinary packing density of the cells, and I believe that our packs are extraordinarily safe. I believe they’re intrinsically safer than the nearest competition, and a lot of that is due to the way that we design our cooling system.

Charged: Will the Lucid Air be offered with one motor, dual motors, or both options?

Peter Rawlinson: Well, both actually. The motors are designed entirely in-house. We have extraordinary gains in efficiency and we’ve got a breakthrough cooling technology, which we’ve patented. That’s really going to give us extraordinary efficiency and range. We believe in having sprung motors, one motor per axle, so the four-wheel-drive version of Lucid Air has two motors and the rear-wheel-drive entry-level model has just one motor at the rear. We don’t subscribe to in-wheel motors.

Charged: Is the issue of unsprung mass the reason that you didn’t go with an in-wheel motor?

Peter Rawlinson: Partly, although the sprung mass effect is actually less detrimental than many believe. The real problems are that there’s an efficiency issue and there’s also a steering geometry and a brake cooling issue, so trying to get the suspension characteristics for a great-handling car would be compromised in a car of this particular class if we were trying to achieve that. There is that unsprung mass issue, which degrades ride, but that’s not the key thing: it’s getting that geometry, the suspension geometry, particularly upfront with the steering geometry, and also getting conventional foundation brake cooling, those are the real killer issues which preclude having in-wheel motors in a class of car like this.

Charged: The Croatian startup Rimac uses four motors and electronic torque vectoring. What are your thoughts on that?

Peter Rawlinson: You can use four motors – and they don’t have to be hub motors, you can have them inboard, sprung mass – and you can torque-vector with that. Now, that is a very purist solution for an ultimate supercar. If you have four small motors, they’re intrinsically less efficient than two slightly larger motors. There’s a subtle difference between torque vectoring electronically with the motor – assuming you can actually do that, because it is hugely challenging software – versus torque vectoring with the ABS system and the brakes working in harmony with the motor. It’s a subtlety that maybe some very elite drivers on a race circuit might just be able to detect, but would you really do that and compromise range for a car designed for everyday use?

I think that this is horses for courses. I think that for an ultimate supercar, probably four motors inboard with torque vectoring is a great solution. That’s what they’re trying to achieve. I believe that solution is inappropriate for Lucid Air. I think for Lucid Air, the priority is phenomenal day-to-day capability, including phenomenal range.

Charged: I’ve read a lot recently about the relative advantages of buying components from suppliers versus building stuff in-house. It sounds like you’re leaning towards the in-house solution – motors, battery packs. Why is it better to do all that stuff in-house?

Peter Rawlinson: There’s a number of reasons. First, if you look at the technology we’ve got on our battery pack, our motor, our inverter, even our transmission, you cannot buy that level of technology off the shelf. It’s simply not available. We benchmarked against some very close competitors, and our performance is shockingly better. There is another electric car company in California, their motor spins around 11,000 RPM, and ours spins about 19,000 RPM. They bought theirs off the shelf from a very reputable motor manufacturer, but they’re limited to 11,000 RPM. As you’re probably aware, the speed of spin is just as important an attribute as absolute torque at zero RPM, that really is that bandwidth that defines the capability of the motor.

Our inverter for the rear is rated at 650 horsepower. It’s truly state of the art. We’ve used our own multi-physics simulation in-house to make what I believe is the most compact and efficient inverter in the world. We benchmarked that against industry leaders, and ours is a step more advanced, in my view.

So, that stuff simply isn’t available off the shelf if you’re reaching for the stars. I want to create the very best car in the world. If you’re reaching for mediocrity, and just want to create another EV, then you can buy that off the shelf.

But the second reason for doing it in-house is perhaps more compelling. We see the five key elements of the powertrain – battery pack, electric motor, transmission, inverter and software – as a really synergous, harmonious system like the human body. It works together as an ecosystem, it’s like matching muscle tissue with lungs and heart rate, these organs are interactive in their capability. If we buy elements off the shelf, that’s a sure-fire way of creating a Frankenstein – that’s the best analogy I can make.

Charged: Are there any major components that you’re buying from other suppliers?

Peter Rawlinson: We’re buying core components – we buy IGBT chips to put into our inverters. We buy our copper wire for the motors. We buy our electrical steel sheets to make our rotors, and we actually buy the cells for our battery pack. We’re not a cell manufacturer – we do that with Samsung and with LG Chem. At a core component level, of course we’re not trying to reinvent the wheel. We’re a tech company – we started as a battery technology company and morphed into a complete EV powertrain company. Then I joined the company a few years ago for it to transition to be a complete vehicle company.

I think that’s really an interesting point, because what we’re doing with Lucid Air, we would not have been able to do if we didn’t have real mastery of that electric vehicle powertrain in advance. We’re using that miniaturization of the electric powertrain as a tool to make the car as a whole better. Although others have shown the viability and even superiority of electric cars now – and I think that’s well recognized by the public, and full marks for doing that – I don’t think anyone has really taken this technology to its natural conclusion – far from it. I think others are making cars which are conventional cars, which are designed to be electric from the ground up, but not reimagined as what the car can be.

With Lucid Air we’ve said, “Let’s look at the size of this electric motor, 600 horsepower developed in-house. It’s a fraction of the size of a 600-horsepower gasoline engine. We don’t have the drive shafts, because there’s two power sources, two motors, we’re not trying to split from one gasoline engine to four-wheel drive. Let’s take full advantage of that compactness and the different shape to reimagine the 3D puzzle that is the design of the car and tease out so much more interior space and have a much bigger, transformatively larger interior and cockpit for the exterior size of the car.”

That’s what’s really exciting about Lucid Air and really imaginative about it. It’s more compact on the outside than, say, a Tesla Model S, it’s shorter, it’s narrower, it’s lower, it’s actually about 43 millimeters narrower. Yet it’s got massively more interior space, particularly at the rear. In fact, we’ve got more interior space than a long-wheelbase S-Class Mercedes. I don’t really think that comes across fully in some of the photographs that are out there on the web. When people sit in it, they’re often amazed and say, “Oh my goodness, I didn’t realize it was going to be as good as this. I see what you guys are doing now, this is extraordinary. This is a real breakthrough. No one has actually done this before.”

Why that matters is, first of all, a more compact car is a better driving car. I love driving it, it’s a really fast real sports car, a fantastic machine to drive. It’s more maneuverable around town, more usable. I’ve driven some of these big cars – we’ve had a Mercedes S-Class as a benchmark vehicle, it’s a fantastic piece of engineering, but it’s not a real pleasurable driving car – it’s just too big for that. Lucid Air is really usable around town – we were driving it in Manhattan earlier this year. It’s easy to turn, it’s easy to park in multi-story [garages]. That agility just shines, and yet it’s got this ultimate luxury space, which no one else has got. I think that’s what makes it a world car, because its compactness will help particularly in markets like Europe and Japan, and yet it’s got that coveted rear seat space that really is so desirable in the biggest market of all, which is China.

The other car companies tend to have a long-wheelbase version of their car and a short-wheelbase [version] for different markets. I think we’ve got it covered – we’ve got a modest wheelbase, with all the handling and dynamic attributes that brings, coupled with its great interior luxury.

Charged: At one point, you said, “I have the key brain power behind the Model S team with me today.” Who are some of the other folks working for Lucid that were on the Model S team?

Peter Rawlinson: In fact, some of my key directors were with me through Model S. I have Eric Bach, who was with Model S and Model X – he is my Senior Director of Body Engineering. On safety, Dr. Louise Zhang, who was Director of Safety for Tesla Model S – I recruited her into the Tesla team. She’s Director of Vehicle Safety here at Lucid. I also have David Mosely, who’s Director of Powertrain here. David was with me on the formative stages of Tesla Model S. Also Roger Evans, Director of Vehicle Engineering here. Roger was responsible for so much of Model S, right through. Then each of them have brought many members of their teams here as well. These were core team members who were so instrumental in many of the innovations that we made.

Charged: What can you tell me about things you learned in designing Model S that made their way into the Lucid Air? Maybe some things you did right, maybe some things you did wrong, some things you did on the Model S that you decided not to do.

Peter Rawlinson: First of all, I’d like to point out that we’re not using any technology from Tesla here at Lucid. We’ve been really assiduous in our endeavor to make sure that there is absolutely no use of any IP from Tesla. We’ve taken a completely fresh look at designing an electric car from the ground up. That has been our approach absolutely throughout. The best way to compete at the top table is with new technology, with our own things. In that sense it’s as if Tesla Model S never existed.

But it’s inevitable with the experience one accrues through one’s career that the lessons learned are etched in our consciousness, and I’d like to think that I’m more experienced at running engineering teams and how to manage that process and how to operate in a more focused and more efficient manner.

One of the things I’d like to say about what we do here is, we are not offering solutions to problems which don’t exist. I believe that the solutions we’re offering at Lucid are of very direct and tangible value to the customer. We’re not doing esoteric door systems, we’re doing comfort and legroom in a very pragmatic and valuable way that you can appreciate and enjoy every mile that is driven in the car.

Charged: Lucid Air is pretty obviously a luxury vehicle. Are you envisioning a future generation that’s more mass-market?

Peter Rawlinson: Absolutely, yeah. We’re at a point in time where battery technology is at a certain price point, and therefore it makes greater sense to start with a relatively upscale product. The other thing is, there’s more than the product to consider here. The first product from a new brand defines the brand, so we have a defining-role function from Lucid Air that it really defines what the brand is about. A great sporting driving experience, the highest of high-tech – just look at those headlights, for example. The car’s just bristling with technology: the vortex air induction system, our super-compact battery pack, its incredible performance – we have 440 miles of range. This is an extraordinary combination of technologies. We have inverted air springs – no one has got that – to reduce the unsprung mass, and we couple them with active damping. This is super high-tech, and it’s better than the competition in many ways. It’s very overtly and deliberately a technical tour de force, because it defines the credentials of the brand. When someone says they own a Lucid, it means something. I want it to have a huge impact.

But of course as battery cells and the price of battery energy come down, we’re looking towards hitting about a magic $100 per kilowatt-hour around 2020 at cell level. That’s going to have a profound effect. People ask me, “Is it energy density that’s going to effect the transition towards mass market for electric cars?” I say, “Not really, it’s going to be the price point. It’s the kilowatt-hours per dollar that’s really going to make a big difference.”

I think we’re timing this just right. I want to do mass-market cars which will really change the world, but we shouldn’t do those yet, and we shouldn’t do those as a first product. But absolutely, they’re going to come.

Charged: I read that the price of the Lucid Air is going to start at $60,000. Is that still the plan?

Peter Rawlinson: That’s correct, and that’s a single-motor, rear-wheel-drive 400-horsepower, 240-mile range car. That’s entry level, but of course, we’ll have a range of prices going considerably up from that.

Charged: You said something in an interview that I thought was very interesting. You said it’s a myth that EVs lose money, but you’re happy to let everyone think that EVs lose money, so that nobody wants to build them. Did you mean that in terms of your EVs? Or did you mean that existing EVs are actually profitable?

Peter Rawlinson: I think it’s public domain information that the margin on a Tesla Model S is now 28%. Here’s the thing: Mercedes Benz averages [a margin of] about 22% and you could go to a really profitable car, maybe a Porsche, which [has a margin] over 30%, but the market believes that Tesla’s an inherently unprofitable company. The product isn’t unprofitable.

We’ve done the math for Lucid Air, and there’s a reason we’re making a luxury car, because at that price point we can make a very healthy traditional margin. That is in a traditional model, as if you were selling a traditional car, but actually we see a more progressive business model where the car can be used as a tool and actually can generate a lot more revenue through the data it accrues. In a sort of shared mobility setting, there’s a beguiling set of opportunities where that 28% sort of margin becomes kind of an old-fashioned way of looking at things.

Charged: You’re referring to a ride-sharing model?

Peter Rawlinson: Yeah, you can have ride-sharing. With the sensor suite that we have on our car for autonomous driving, the data that can accrue, the value and monetization of that big data can actually be part of the revenue stream the car can accrue. So we’re looking forward to a new sort of model, which kind of transcends that view of selling a car and the margin you make on selling that piece of hardware.

Charged: What technical features does a car need to have to optimize it for an autonomous ride-sharing application?

Peter Rawlinson: Autonomous and ride sharing are two slightly different things, but if you sort of fuse those together I think that what really matters for ride-share is…it’s about the rear seat experience, it’s about leg room, it’s about ease of getting in and out of the rear. For example, Lucid Air is not really designed specifically as a ride-share vehicle – it’s more of a luxury product with that sort of capability in mind. Our rear doors open fully to 90 degrees, our rear aperture for getting in and out is sculpted in a very ergonomic way, a very unusual manner actually, compared with the profile of most cars out there, which makes getting in and out of those rear seats and enjoying that experience very accessible.

In terms of having the car autonomous-ready, we have endowed it with a very comprehensive set of sensing hardware. We recently announced a technical partnership with Mobileye for sensing, so we have cameras, lidar and radar, both short- and long-range. We really believe in the value of having an overlay of lidar working interactively with the radar, so we get a degree of redundancy in that sensing. Again, perhaps I can point to the human body as a sort of analogy. When we walk around, the brain beautifully fuses visual inputs with balance inputs from the inner ear to see where we are and that we don’t fall over. If you close your eyes, it’s not so easy to walk or jog. When one loses control of one’s inner ear, even with the visual input, balance is difficult. Just as the human brain fuses that balance and that visual sensing, I think it’s really important that these autonomous vehicles can fuse different inputs from cameras, radar and lidar.

One of the reasons for that is the range of inclement weather that can be experienced in certain cases, you can have sleet, snow, fog, you can have rainbow effects, reflected light, intense sunlight, headlights, reflected headlights, spray.

We merged that [sensor suite] with massive onboard processing and very considerable onboard data storage with a high degree of connectivity for the car. That’s the key hardware systems which were integrated into Lucid Air to enable it to be a full Level 4 or even Level 5 autonomous-ready as soon as legislative conditions allow and/or as soon as the appropriate software will be available. When we go to production, it will be sort of Level 2, (or two and a half, depending upon your definition) at the get-go, and then we’ll be able to flash over the software to make it Level 4. Nobody knows exactly when that will be.

Charged: Have we got a rough delivery date yet?

Peter Rawlinson: We’re about two years out. We’ve secured the [manufacturing] site in Casa Grande in Arizona, between Phoenix and Tucson. We’re about 24 months out from the start of production.

Charged: I understand that you’re going to be supplying batteries for Formula E.

Peter Rawlinson: Since you ask, I can disclose that before we branded as Lucid, the car company, our name was and remains, actually, Atieva. Atieva is delighted to partner with McLaren Applied Technologies of Formula One fame, and Murata, formerly Sony cells, to supply the Formula E packs. It’s the Atieva design, and that will be for seasons five, six and seven, starting in late 2018. That’s not Lucid – I want to be really clear, that’s not under the Lucid banner, that is an Atieva project.

This article originally appeared in Charged Issue 36 – March/April 2018 – Subscribe now.