Detroit is gradually losing its position as the epicenter of the auto industry. Nowadays, news of cutting-edge developments is more likely to come from Silicon Valley, Europe or China. The Eastern European nation of Croatia is pretty far from the centers of automotive power, but it’s here that a highly innovative firm called Rimac Automobili is building electric supercars.

The company was literally born in a garage in 2009, in the small town of Sveta Nedelja, just outside Zagreb, and named for founder Mate Rimac. It began attracting attention within a year, as a test mule based on a BMW M3 started winning races against legacy gas-powered cars (the e-M3 went on to set five Guinness and FIA world records for EVs). In 2011, the company showed its Concept_One electric supercar at the Frankfurt Motor Show. In 2014, the Concept_One achieved worldwide visibility as the official Race Director Car for the Formula E racing series.

Let’s get the inevitable comparison with Tesla out of the way. Like the young Elon Musk, Mate Rimac has big dreams and a clear vision, and he has accomplished things in a short time that establishment figures would have said were impossible. In a country that had no existing auto industry, Rimac has built a company that’s selling cars and components around the world, and has been recognized as a great national asset.

“We are a true engineering company, with about 50% of our 190-person team devoted to engineering and design,” founder and CEO Mate Rimac told Charged. “A major challenge was to build that team in a country that never had a car industry and has only a few high-technology companies. That meant we had to go through a lot of trial-and-error iterations and learn from our own mistakes. That process bonded our team and created a family.”

Rimac has been voted the best employer in Croatia, and is one of only a few high-tech manufacturing companies in the country, so it attracts the best talent in the industry. “What the local workforce lacks in industry experience is made up by their enthusiasm and drive,” says Mate Rimac.

Rimac is following the time-tested strategy of developing technology for a high-priced, low-volume product, then using the lessons learned to build a higher-volume model. However, unlike the Californians, the Croatians have no plans (yet) to expand to the mass market.

The company revealed a production version of the Concept_One at the 2016 Geneva Auto Salon. Production will be limited to 8 units, but the company is working on a new, higher-volume model, to be unveiled in 2017. “We are a supercar manufacturer, so don’t hold your breath for a high-volume family car, but we do plan to go in the hundreds of units territory,” Mate Rimac told us. No details of the next-gen model are on offer at the moment. “We have decided to unveil new models only when they are ready for production and not as concept cars.”

If you want something done right…

Rimac does not follow the usual auto industry practice of contracting with outside suppliers to design and manufacture components. Almost everything that goes into the Concept_One is developed in-house, and built right in Sveta Nedelja. Perhaps this policy was partly born of necessity (automotive suppliers are few in Croatia).

Rimac’s web site explains its philosophy thus: “Painstaking attention to every detail requires high quality, which can best be maintained and controlled if the engineering and manufacturing teams are under the same roof. Thousands of metal, electric and carbon fiber parts have to be manufactured, assembled and tested for each Concept_One. Even the tools, jigs and molds are designed and produced by Rimac Automobili.”

“At our core, we are a technology company,” says Mate Rimac. “Most technologies and components that you can find in our car are developed and manufactured on-site in our facilities. Other than the obvious electric vehicle components such as battery systems, we are also manufacturing all composite and metal parts, electronics, infotainment, chassis, suspension components, etc. in-house. We are one of the few places in the world where you can start with a blank sheet of paper and raw material and design and produce a whole car in one facility.”

Spreading the gospel

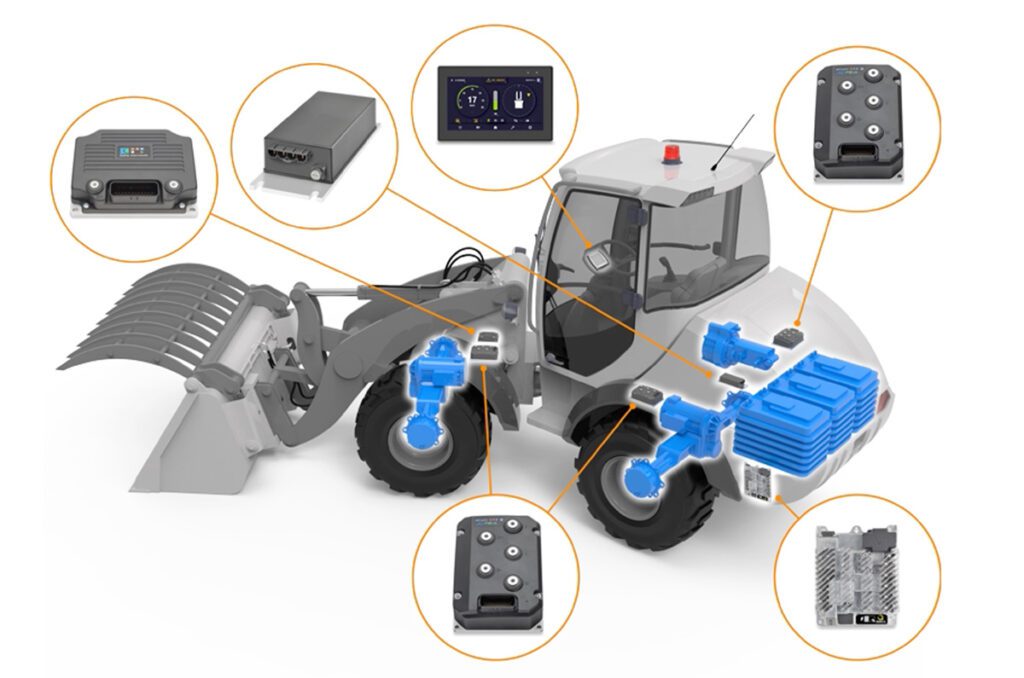

Rimac also licenses its technology and engineering services to other manufacturers. “We provide a wide range of products and services to our customers,” says Mr. Rimac. “We are supplying components such as batteries, ECUs, and infotainment systems for some projects, while for others we handle the full vehicle development program, including small batch production runs for a range of applications and industries – from supercars to vessels to wheelchairs.”

Many of these collaborative projects are top secret, but at least two are anything but.

The Koenigsegg Regera, the brainchild of Swedish supercar designer Christian von Koenigsegg, is billed as the world’s most powerful car. With a V8 engine and two electric motors cranking out 1,500 hp of total power, and 2,000 Nm of torque, few would argue. Rimac supplied several components for this work of automotive art, including a 9.27 kWh battery pack that can deliver 500 kW of power and absorb 150 kW during regenerative braking, and weighs only 115 kg.

Rimac also collaborated with Monster Sport to build a custom car for the Pikes Peak International Hill Climb. Legendary driver Nobuhiro “Monster” Tajima drove the E-Runner Concept_One to win second place overall (EVs and ICEs) in 2015 and fifth overall this year.

Multiple motors, one team

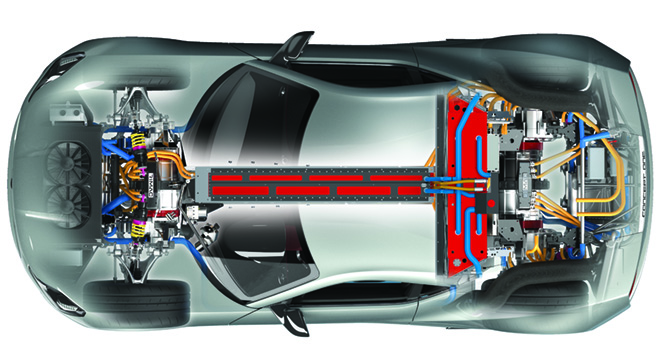

Designing things in-house enables Rimac to maximize the advantages of a native-built EV. The Concept_One’s powertrain and chassis were developed in parallel by engineers working within the same team. The resulting automobile boasts a high degree of integration among components, near-perfect weight distribution and an extremely low center of gravity.

EV designers are discovering the advantages of using multiple motors – after all, electric motors are compact and inexpensive compared to those noisy, belching things called ICEs. Whereas Tesla’s premium models use two motors, the Rimac supercar has no less than four permanent-magnet oil-cooled motors (designed and built in-house, of course). There are two 500 kW (peak) motors in front, and two 600 kW units in the rear. All four deliver 12,000 RPM at up to 97% efficiency.

“The Concept_One’s powertrain is divided into four sub-systems, each consisting of one motor, inverter, and a reduction gearbox,” Mate Rimac explained to us. “Each of the systems drives one wheel, completely independent one from the other. Sophisticated ECUs control each of those systems using the input of many precise sensors placed all over the car. This architecture allows a new approach to vehicle dynamics, which is called Rimac All Wheel Torque Vectoring (RAWTV). We can control the torque on each motor, and thus on each wheel, 100 times a second. The result is incredible control and adaptability of vehicle behavior, a high level of safety and usability in every condition for all kinds of skills, maximized regenerative braking and fine-tuned traction control.”

The RAWTV system calculates the optimum torque for each wheel, functioning as both traction control and stability control. It also controls the 4-wheel regenerative braking of up to 400 kW, and the carbon-ceramic brakes. Rimac says that RAWTV can distribute the brake force faster, more smoothly and with greater precision than conventional ABS systems, ensuring maximum vehicle stability.

The settings of the RAWTV system can be adjusted to change the handling of the car. Driving modes include Comfort, Control, Track and Drift mode, and drivers can also create their own custom settings.

What are the pros and cons of Rimac’s 4-motor design compared to an in-wheel hub motor? “In-wheel hub motors add unsprung mass that results in higher stress to suspension components,” says Mr. Rimac. “Our motors sit low and inboard, close to the center of the car, which we consider to be better for vehicle dynamics. In-wheel motors have to run at the same speed as the tires, which is a limiting factor. High-speed motors tend to be lighter, so gearing the motors up to high RPMs gives weight advantages. While there are many advantages to a four-motor setup, it brings a high level of complexity in the development process and requires a talented vehicle dynamics and control software engineering team to get the most out of the system.”

Shifting gears

Most EVs use a single-speed transmission, but Rimac points out that this forces designers to compromise between acceleration and top speed.

Each of the Concept_One’s four motors is coupled to a proprietary gearbox system. While the front motors feature single-speed gearboxes, each of the rear motors has a two-speed double-clutch gearbox. A proprietary carbon fiber double-clutch system with Formula 1 clutch disks enables either extremely fast or smooth and comfortable shifts that are supported by synchronizing motor speed for uninterrupted shifting.

Rimac assures us that the Concept_One can also be driven in one gear all the time, as it still has enough torque to smoke almost any sports car.

The Concept_One’s proprietary battery pack consists of 8,450 battery cells, each individually controlled by the Rimac Battery Management System (also developed in-house). Rimac also developed a unique liquid thermal management and low-resistance conducting system for the pack. The pack is designed to deliver 1,000 kW of power, and can absorb 400 kW during braking.

All functions of the Concept_One are controlled by a single unified computer system, which gathers information from over 500 sensors and can send telemetry data to the cloud, and thence to a smartphone or other viewer. Vehicle dynamics and powertrain functions are controlled by high-grade aluminum buttons (yes, even these are made in-house), while secondary functions are controlled through the central touchscreen.

Rimac’s roots are in racing

“Racing affects technology like war,” says Mate Rimac. “You are encouraged to develop things quickly. You break stuff, improve and try again. It is a fast-track development process. If something works well on a racetrack, it should perform great on the road. The challenge is to bring the cost down for a non-racing application.”

“The Tesla Model S has great performance for a couple of 0-60 mph acceleration runs [but] many powertrain components face thermal challenges on the track. We want to make sure that our customers can have fun with their cars on tracks and perform well over a longer period of time. Our industrial customers often have the same requirement – the Koenigsegg Regera 9 kWh battery has to be able to deliver 500 kW of power for a long time, as the car carries basically a 1 mW power station in the form of an 8-cylinder bi-turbo combustion engine which constantly recharges the battery at high rates.”

Lessons learned on the track are valuable not only for building supercars, but also for more mundane vehicles. “We are using our experience to incorporate many of the design features of our high-performance battery systems for applications that require affordable systems, like our nautical, bike and wheelchair projects.”

“The torque vectoring is a perfect example of a technology transfer from road cars to racing and back – we took the Concept_One torque vectoring system and adapted it for the Pikes Peak Hill Climb. There we learned so much, and improved the system on so many levels that we have implemented the racing system back into the road car.”

Speaking of racing, Rimac has also built an even more powerful car that it calls the Concept_One’s Evil Twin. The Concept_S boasts a screaming 1,384 hp and 1,800 Nm of torque. It’s 50 kg lighter than the Concept_One, and features special aerodynamic elements – a front splitter, air deflectors, side skirts and a large rear spoiler – that enhance downforce by 34 percent. The interior has been stripped of sound insulation and equipped with racing seats with four-point racing harnesses.

Battery balance

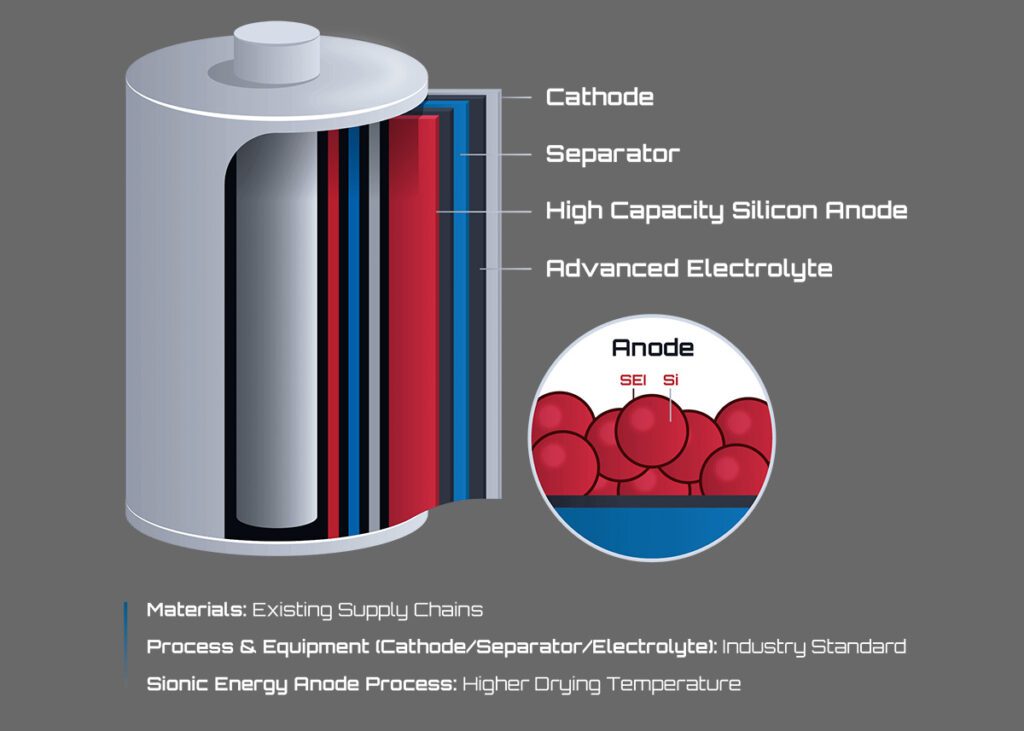

When we asked Mate Rimac what he thought about new types of battery technology such as solid-state electrolytes, silicon anodes, lithium-sulfur, etc., his answer was reminiscent of comments that Elon Musk and JB Straubel have made – so far, there’s nothing that beats Li-ion cells on all the parameters that are required in an automotive battery.

“Since I started to get involved with electric vehicles, new technologies have been announced, but not much has happened since then. Lab-level tests demonstrate good results in some aspects such as the recharge time, but a good battery needs to offer excellence in power density, energy density, cycle and calendar life, safety, operating temperatures, cost, etc. People always focus on one thing at which new promising technologies are really good at, but we can’t know their true suitability for a vehicle application until we can get our hands on them and test them. We are leveraging the best technologies available and use different chemistries and cell suppliers depending on project requirements.”

This article originally appeared in Charged Issue 26 – July/August 2016. – Subscribe now.