Researchers at the Oak Ridge National Laboratory (ORNL) have developed a way to mitigate the risk of battery failure during automobile accidents by including slits along the electrodes.

In “Limiting Internal Short-Circuit Damage by Electrode Partition for Impact-Tolerant Li-Ion Batteries,” published in the journal Joule, the research team explains how this technology could allow manufacturers to scale down the housing materials that protect batteries in EVs from mechanical damage, improving pack-level energy density and reducing cost.

“Small batteries pose a much smaller hazard when they are accidently shorted than do very large batteries,” says study co-author Nancy Dudney, an energy storage researcher at ORNL. “Our innovation may allow the large batteries used in most vehicles to fragment into many small batteries if damaged in a collision. With such an innovation, device manufacturers can reduce the weight and expense of heavy-duty containers that are normally needed to protect their batteries from mechanical abuse.”

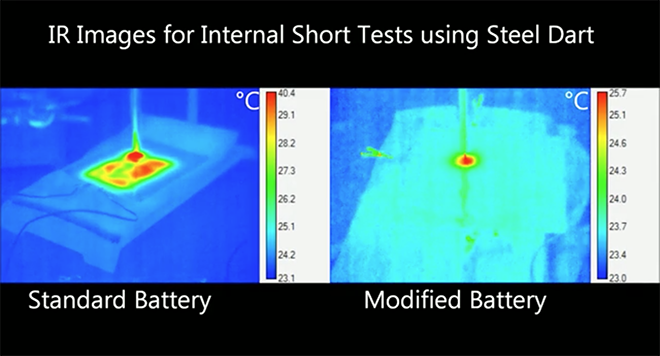

Dudney and her team lowered the risk of a battery failing during a crash by adding slits as perforations along the electrodes. These slits are designed to break the electrodes into tiny fragments during an impact, dividing the battery’s energy into smaller components and making it less likely that the temperature will rise beyond a level the battery can handle. In the event that a short does occur, the fragments limit the current and heating at the site.

“Safety glass was our inspiration,” says Dudney. “Sometimes the best way to help protect against a dangerous failure is to allow a component to fail or break gracefully and safely under mechanical abuse.” The team tested their model against a standard lithium-ion battery by pressing a large metal ball into each. The modified battery was distorted like a potato chip but continued to function at 93% of its original capacity. Similar damage to a standard battery causes a full discharge and failure.

Since the electrode slits only added a minimal cost to the production of their redesigned lithium-ion battery and didn’t call for significant changes in how the battery was made, the team believes this technology could be scaled up in the future. However, there are still many more tests to run. “We only tested a handful of cells, and this impressive performance needs to be replicated 100 or 1,000 times for good statistics under a wide range of duty cycles,” says Dudney.

Source: EurekAlert!