Solid-state battery (SSB) technology developer ION Storage Systems (ION) has invested in a new pilot production ceramic sintering furnace at its Beltsville, Maryland facility.

The new equipment is intended to increase ION’s annual ceramic production capacity by ~1,000 times and unlock the ability to rapidly scale to hundreds of megawatt-hours through future expansion.

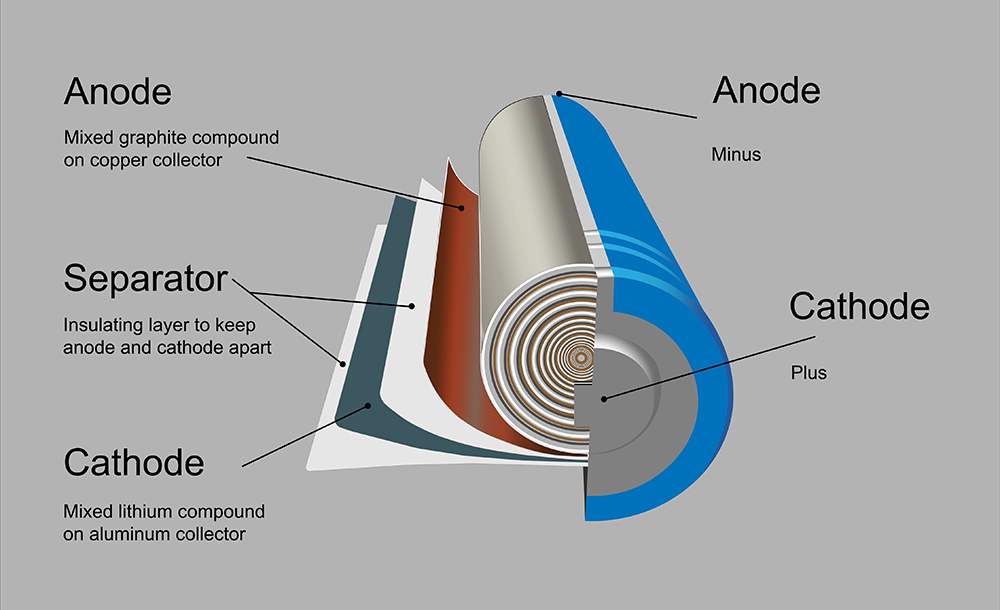

Sintering is a major processing step in forming ION’s ceramic electrolyte, which is the core of its solid-state battery technology.

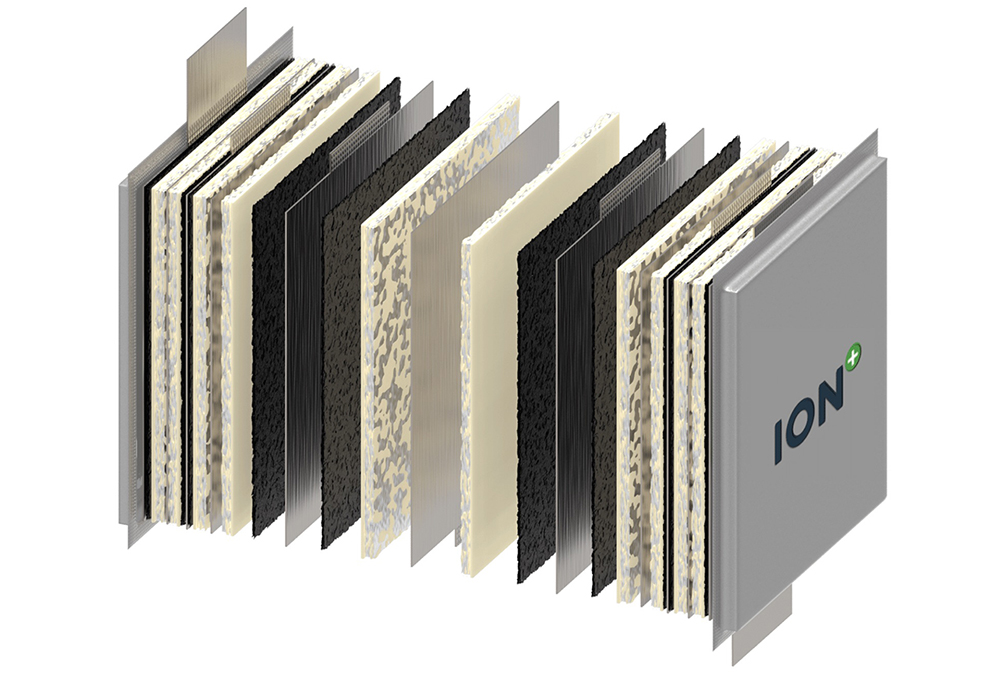

ION’s ceramic solid-state platform is based on a compressionless, anodeless and 3D-structured architecture, eliminating the high-pressure packaging constraints that have historically hindered the adoption of solid-state batteries. The new advanced process equipment is specifically designed to support this architecture, optimizing the sintering process to produce high-performance ceramic electrolyte at scale.

Unlike conventional solid-state designs that require pressure to maintain contact between layers, ION’s zero-compression approach enables modular and scalable stacking, leading to improved safety, manufacturability and design flexibility, according to the company.

The investment follows ION’s production of multi-layer solid-state battery cells on its semi-automated manufacturing line, marking a step toward full commercialization. The company commissioned its pilot line a year ago.

“Our new sintering furnace gives us a clear path to reach commercial scale as well as serve as the launchpad for future expansion,” said Dr. Greg Hitz, co-founder and CTO of ION Storage Systems. “We will have the infrastructure in place to deliver our current footprint as well as expand to large-format solid-state batteries, accelerating our ability to meet growing demand from OEMs, integrators, and government partners across market segments like consumer electronics and EV.”

Source: ION Storage Systems