US-based testing systems supplier Instron has released the AVE3, a non-contacting video extensometer that delivers precise strain measurement for tensile, compression and bend testing, including of battery materials.

The AVE3 can measure modulus and strain to failure on a range of materials such as plastics, metals, composites, biomaterials, textiles and elastomers. It can be used in the process of testing battery materials such as separator films and foils, foams that help insulate, absorb shock and mitigate thermal runaway, and aluminum sheeting used in cell casings.

Compliant with the ISO 9513 and ASTM E83 standards, the AVE3 allows labs to reliably test to any standard with one device, without needing to purchase and maintain multiple clip-on extensometers.

The AVE3 can be configured to accommodate a range of gauge lengths and elongations. New kinematic mounting enables each lens to automatically snap into the factory-calibrated location to capture accurate data easily.

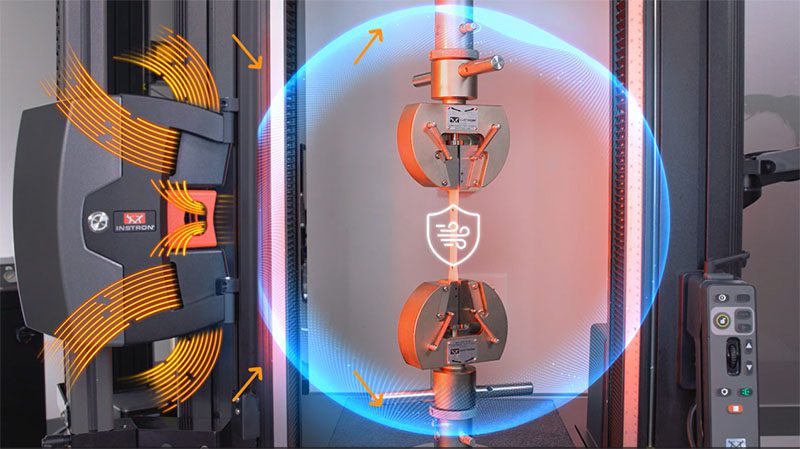

The AVE3 uses Instron’s Constant Density Air Tunnel (CDAT) technology, which creates a force field–like protective barrier around the test space, to guard against typical lab air disturbances such as HVAC systems and human operators’ movements. The CDAT airflow technology eliminates errors, reduces noise in test data, and improves accuracy by as much as five times compared to video extensometers without CDAT technology, Instron said.

Additionally, Instron’s Dynamic Cross-Polarized Lighting system dynamically adjusts its illumination levels to ensure all markings on the specimen are well illuminated for consistent results in various test environments.

Designed for compliance with ISO 6892-1 and ASTM E8, the AVE3 extensometer enables closed-loop strain rate control—the preferred mode for testing strain rate–sensitive metals. This is valuable for laboratories focused on achieving consistent, repeatable results across different systems and locations.

The AVE3 ships with a new, simplified calibration plate that can clip directly onto the specimen, keeping the load string intact, making it easier for operators or managers to confirm that their existing calibration is still valid. Full calibrations can be completed in less than a minute, reducing the time it takes to begin testing.

Optional add-ons for the AVE3 include AverEdge32TM, which simultaneously measures strain at 32 locations along the specimen gauge length, then averages them in real-time, providing a repeatable transverse strain value that is critical for calculating the r-value of sheet metal, per ISO 10113 and ASTM E517.

“Environmental variability has long been the Achilles’ heel of optical strain measurement. Even minor shifts in lab temperature or lighting can introduce significant signal noise and undermine data integrity,” said Casey Willis, Instron’s Product Manager for Strain Measurement Devices. “The AVE3 directly addresses these pain points with its CDAT (Constant Density Air Tunnel) airflow technology and illumination system—two core innovations that ensure consistent data, even in variable lab conditions.”

Source: Instron