By Markus Beck, Sensata Technologies

In advanced battery systems, the quality of the power electronics helps determine the quality of the final product, its level of functionality, and its reliability. This is emphasized in the latest battery power management and charging systems that use wide-bandgap semiconductors and improved power topologies. In such advanced electronics, if the safety systems do not work quickly and reliably, the entire battery system can suffer a catastrophic failure that could seriously impact the product and its user.

The demand for improved stored-energy systems

Almost every advanced application space currently under development requires next-generation battery systems. Smart grid-level energy systems need more power storage just as much as advanced electric vehicles do, and those needs are literally connected. Each space has its own requirements, but the core need of safe, reliable, and economical energy storage is fundamental.

In life-critical application spaces such as automotive safety, the importance of fail-safe subsystems is paramount. The battery system in an EV is similar to the gas tank in a fueled vehicle, in that the stored energy needs to be safe. There is a lot of energy in a modern battery, and catastrophic failure can certainly involve thermal runaway (fire). The increasing level of publicity being given to EV fires has brought more attention to this danger, which is why safety concerns must be addressed in order avoid adversely impacting public EV adoption.

The higher cell densities in advanced battery systems demand proper safety protocols and devices as the power levels involved present a significant challenge when it comes to managing short circuits. To create a robust and safe system that helps ensure reliability over a given vehicle’s lifetime, manufacturers must integrate high-performance components into their designs.

The role of fuses and contactors

Fuses, or similar devices, are required circuit-protection components that protect the system in the event of a short circuit by breaking the line under specific conditions. There are many types of fuses, but the primary element in each is a piece of engineered conductor, usually metal, rated to fail (melt) in a controlled manner under the raised line temperature conditions from a short circuit. This destructive protection method ensures the safety of the circuit by completely severing the power source.

This burn-out response has some drawbacks however, most notably that a power circuit under load will not necessarily have a consistent flow of current. In designs requiring pulses of high power, the wide operating range of current drives the use of a higher current fuse to avoid nuisance tripping, but this leaves the system more vulnerable to overheating and thermal issues. That, and the non-reversible aspect of fuses, has led to the increasing use of electromechanical safety devices like circuit breakers, which can be reset as they do not rely on destructive elements to function.

A contactor is another type of electromechanical protection device, but it differs from a circuit breaker in that it is not intended to interrupt a short. Designed to connect directly to high-current loads, contactors are high-power switching devices operated by an external control. Power contactors are preferred in demanding situations where circuit resetting is needed and high current levels are present. Though similar in operation to relays, contactors differ in robustness and available features to control and suppress arcs created when switching.

When it comes to battery systems, high voltage contactors provide safe circuit continuity in hybrid and electric vehicles, as well as in charging systems and high-powered industrial applications. These types of contactors can rapidly and securely connect and reconnect the circuit, managing arcing and inrush situations. For example, in EVs, normally open contactors safely join the battery pack to the system, disconnecting when the vehicle is not in use.

A faster and more precise solution

There are a variety of circuit protection solutions that can open a circuit faster than a fuse and can do so closer to normal operating conditions without nuisance tripping, resulting in less potential for damage than if a thermal fuse were used. One such solution is the GigaFuse from Sensata Technologies’ GIGAVAC brand, which is a fast-acting, hermetically-sealed electromechanical device with low heat generation that allows for circuit trips at exact currents and features a design that significantly reduces resistance, eliminates thermal aging, and increases system efficiency.

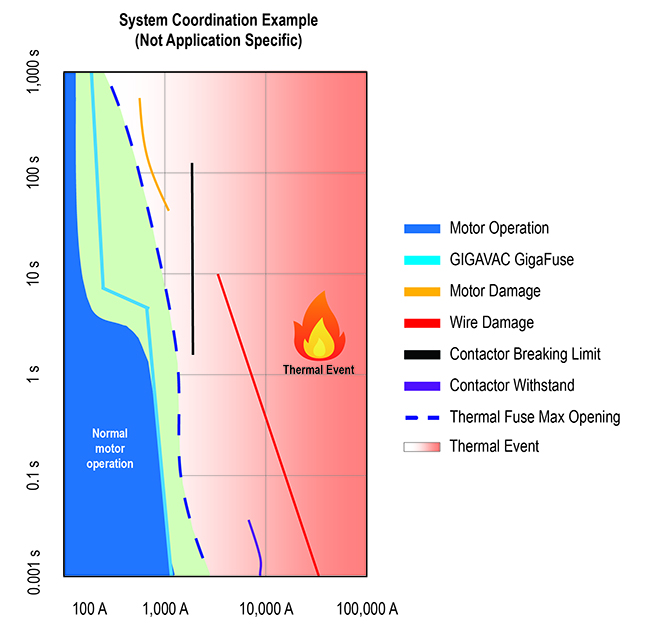

Available in both passive and passive/active combinations, this device uses the magnetic field of the current, the Lorentz force, to trigger the device to open. The figure below shows an example of how the GigaFuse operates, with the blue line representing the triggering threshold, showing that the device can open the circuit faster than a fuse and closer to the desired operating conditions. The triggering threshold’s path can be adjusted, based on the construction of the circuit-tripping device.

Fuses that generate little heat in operation are immune from the thermal aging and related nuisance tripping caused by hot/cool cycles in the circuit. Such temperature cycles over time can cause the conductor metal in fuses to become brittle, reducing operational life by compromising the physical integrity of the connection. Engineers should specify fuses with fast and consistent clear times regardless of ambient temperatures. These features allow the end user to design a safe circuit while at the same time reducing the performance requirements of the contactor.

Proper fuse selection can also improve the performance of the contactor in the circuit. A contactor that is paired with the wrong fuse can actually prevent the fuse from doing its job. As the contactor levitates, it starts to dissipate some of the energy that should be available to trigger the fuse, instead, loading the current on the contactor. An overloaded contactor can prevent the fuse from “seeing” the short, which can result in catastrophic failure.

Moving forward

The ability of electrical protection devices to address circuit safety in high-power systems is not restricted to advanced batteries. A multitude of applications, from motion control to alternate energy generation, can benefit from such a component’s efficiency, thermal performance, and speed. This type of fast-acting, hermetically-sealed electromechanical device is especially beneficial in situations where thermal aging or nuisance tripping are problematic.

Advanced battery systems need advanced circuit protection solutions, for reasons ranging from increasing battery safety and performance to encouraging greater market acceptance of EVs. The high current levels and power densities in next-gen battery systems demand equally high-performance safety components. Circuit protection solutions like the GigaFuse enable designers to provide the levels of protection that are required for the advanced battery systems of today and the future.

Check out the GigaFuse online to learn more or view a specification sheet.