Daido Steel and Honda have collaborated to develop a hot deformed neodymium magnet that contains no heavy rare earth elements, but still delivers the high heat resistance and high magnetic performance required for a hybrid vehicle motor.

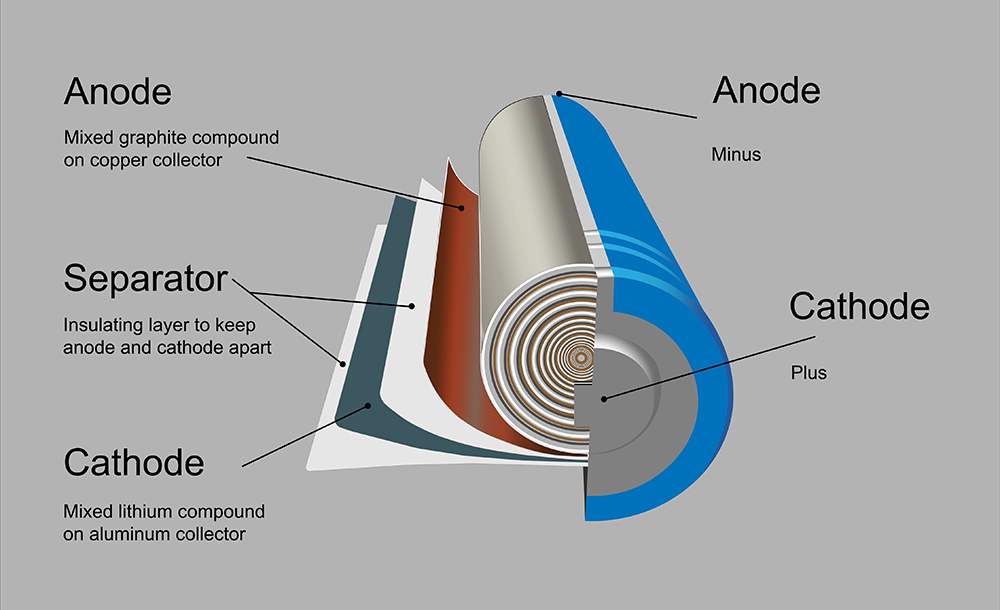

Neodymium magnets are prized for use in electrified vehicle motors, as they have the highest magnetic force of any type of permanent magnet. However, such motors demand high heat resistance properties, which have traditionally been secured by adding heavy rare earth elements (dysprosium and/or terbium).

However, there are concerns about the availability and environmental costs of heavy rare earth elements, and the auto industry is keen to reduce their use.

Daido Electronics, a subsidiary of Daido Steel, has been mass-producing neodymium magnets using the hot deformation method, which differs from the typical sintering production method. Honda contributed its experience in the development of drive motors, and together the companies were able to achieve a practical neodymium magnet that contains no heavy rare earth materials.

Heavy rare earth-free magnet

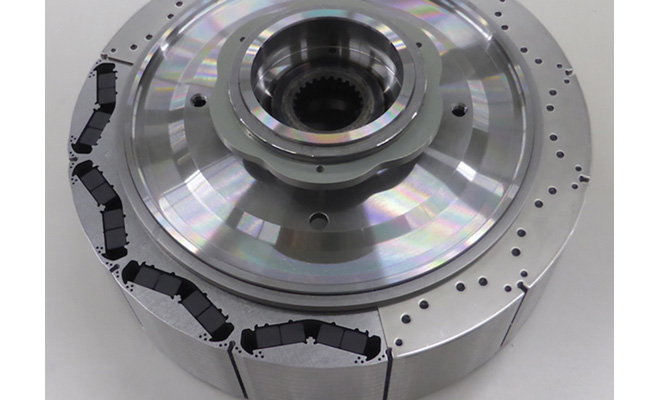

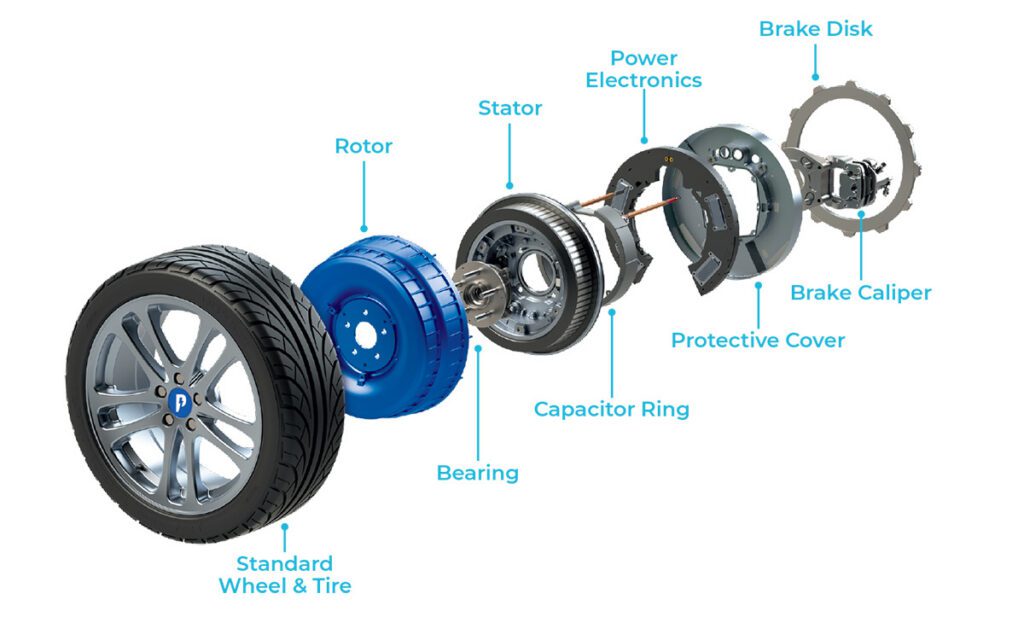

Honda designed a new motor to accommodate the marvelous magnet, revising the shape of magnet and rotor to optimize the flow of magnetic flux. The new motor demonstrates torque, output and heat resistance equivalent to those of a motor with conventional magnets.

Honda’s first application of the miracle magnet will be in the Sport Hybrid i-DCD (Intelligent Dual Clutch Drive) system, which the company plans to use in its all-new Freed (a model similar to the Jazz/Fit, sold in Asian markets), scheduled to go on sale this fall.

SEE ALSO: MotorBrain to debut integrated EV drivetrain with no rare earth metals

Source: Honda via Green Car Congress