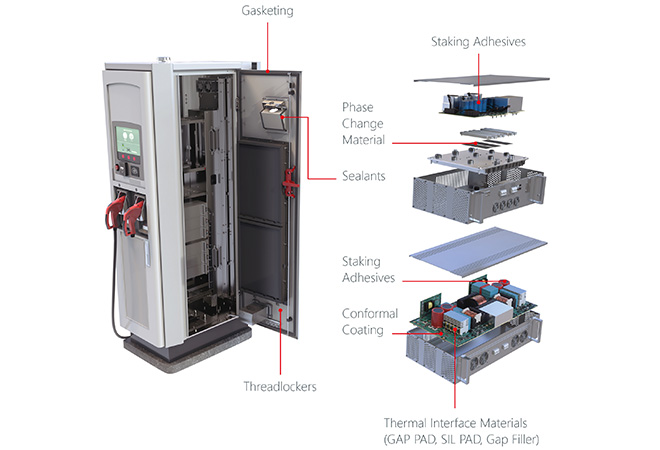

German chemical company Henkel offers a range of materials designed to increase the reliability, safety and cost-effectiveness of EV chargers.

According to Henkel, its Bergquist phase change, GAP PAD and gap filler thermal interface materials provide effective heat dissipation and support reliable operation in the power modules of EV chargers. The company’s sealants and Sonderhoff formed-in-place foam gasketing technology act as shields against moisture, dust and changing environmental conditions. Henkel says its potting materials contribute to the durability of charging connectors and help protect them from wear and tear, rough handling, vehicle rollovers and moisture.

“With solutions that are easily automated, costs are driven out of the manufacturing process while building reliable, rugged devices that will satisfy consumer expectations for all levels of EV charging devices,” says Henkel’s Director of Market Strategy for Power and Industrial Automation Justin Kolbe.

Source: Henkel