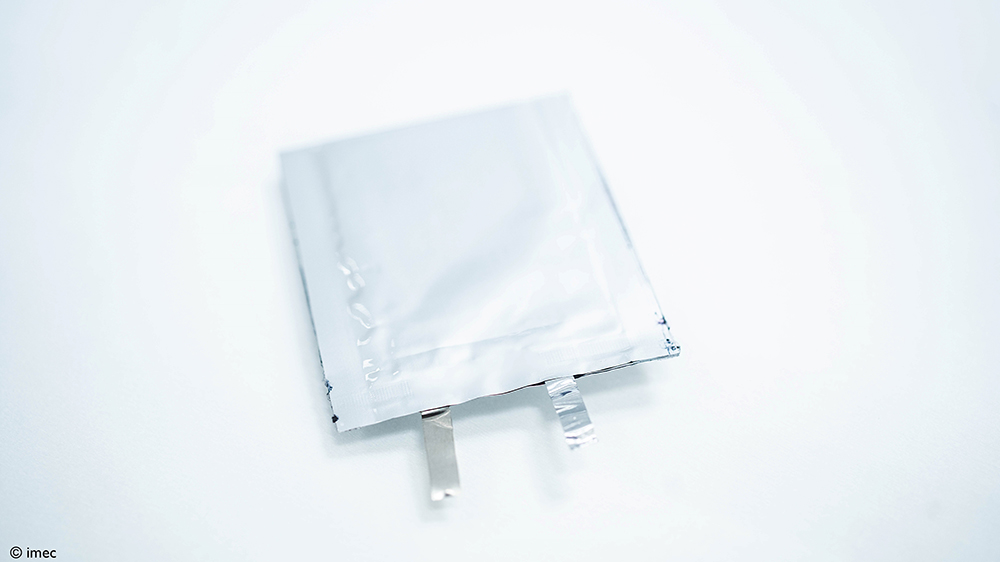

The H2020 SOLiDIFY consortium, coordinated by Belgian research organization Imec, has developed a lithium-metal solid-state battery with high energy density.

The prototype battery pouch cell, manufactured by Imec in the assembly lab at EnergyVille, Belgium, has a “liquid-to-solid” processed solid electrolyte, which was jointly developed by Imec and its 13 consortium partners. The cell has an energy density of 1,070 Wh/L, which is above the maximum of 800 Wh/L for lithium-ion technologies, according to Imec.

The manufacturing process is manageable at room temperature, adaptable to current lithium-ion battery production lines and projected to cost less than €150 ($166) per kWh.

For the prototype’s solid electrolyte, a doped polymerized ionic liquid (PIL)-based nanocomposite material was used, enabling the liquid solidification approach. Combining a high-capacity composite cathode separated from a thin lithium metal anode by a thin solid electrolyte separator (50 μm) resulted in high energy density and a compact battery cell stack.

The cell’s charge rate increased to 3 hours and its lifetime to 100 cycles, overcoming mechanical strength and cathode impregnation challenges. The thermally stable solid cell had lower flammability than liquid electrolytes. The application of nanometer-thin protective coatings enabled the use of cobalt-lean cathodes.

The SOLiDIFY consortium comprises 14 partners: research centers imec/EnergyVille, Fraunhofer, Centro Richerche Fiat SCPA, Empa, Hasselt University/EnergyVille and Delft University of Technology, as well as industry partners VDL Groep, Umicore, Solith, SOLVIONIC, Sidrabe, Leclanché, Gemmate Technologies and Powall.

The project ended in June 2024 but as a next step, the partners will further upscale the battery technology. Imec aims to continue increasing the energy and power density of energy storage technologies and research next-generation cathode materials and lithium-metal anodes using electroplating.

Source: Imec