As part of Germany’s Visio.M electromobility project, researchers at Munich Technical University (TUM) have developed a torque vectoring transmission that’s designed to improve handling and recoup the maximum amount of braking energy.

“While drive torque is normally distributed 50/50 to the wheels of the drive axle, our torque vectoring system doses the torque between the wheels as required,” explains engineer Philipp Gwinner of TUM’s Gear Research Center (FZG). “This also ensures particularly good drive dynamics.” When a vehicle accelerates in a curve, greater torque is applied to the outside wheel. The car steers itself into the curve, resulting in greater agility and safer road handling.

Even more important to the researchers, however, is the efficient recovery of braking energy. In curves, the recuperation of braking energy is limited, as the inside wheel bears significantly less load than the outside wheel. The torque vectoring function adjusts the recuperation torque for both wheels individually, allowing more energy to be recovered.

DON’T MISS: A closer look at regenerative braking

Torque vectoring transmissions are currently found only in high-end sports cars. Due to the high cost and additional weight, such a system has yet to be used in a production EV. The aim of the researchers was to optimize the transmission for small vehicles with electric drives.

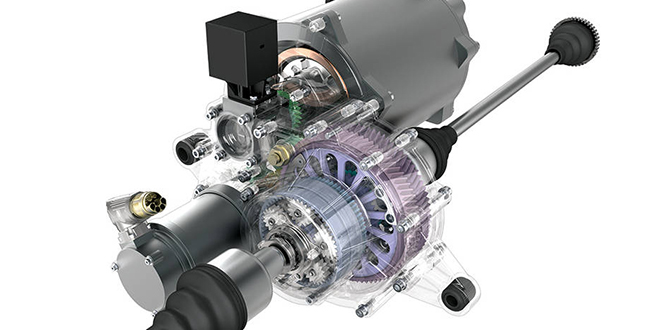

Instead of the standard bevel gears used in differential transmissions, the engineers developed a spur gear differential in which additional torque can be applied from outside via a superimposed planetary gearbox. Using a small electric torque vectoring machine, they can generate a large yaw moment at any speed to achieve the desired road handling dynamics.

“The elegant thing about the torque vectoring transmission we have developed is that it not only has a higher recuperation level, and increased driving range,” says Professor Karsten Stahl, Director of the FZG. “The transmission also improves road handling dynamics, driving pleasure and safety. The continuously improving optimization measures leave us optimistic that in the near future both the weight and cost will be able to compete with today’s standard differential transmissions.”

Source: Technische Universität München via Green Car Congress