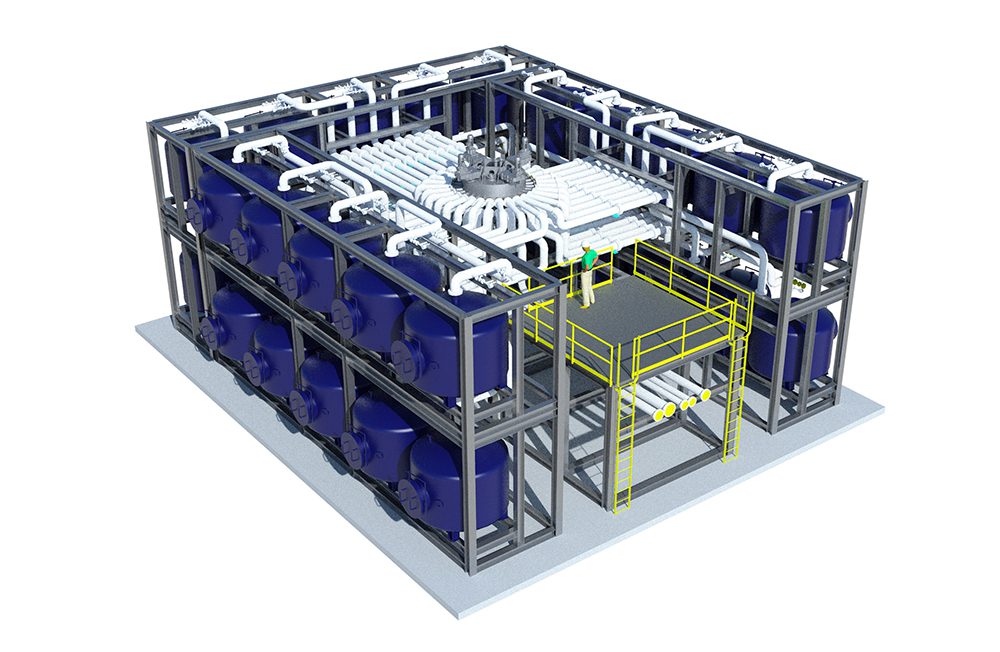

FREYR and 24M have signed an agreement to use 24M’s SemiSolid lithium-ion battery platform technology in FREYR’s planned facilities in Norway.

FREYR is targeting a production capacity of over 40 GWh of scalable, modular battery cells via partnership-based strategies in both grid and electric mobility markets.

“24M has fundamentally redesigned the traditional LIB cell technology and production platform, delivering higher energy density per battery while enabling a substantial reduction in Capex, operating costs, CO2 emissions and physical footprint of the manufacturing facility as compared to conventional solutions,” said FREYR CEO Tom Jensen. “By combining the 24M platform with access to clean, low-cost renewable energy and Norway’s highly skilled engineering-based workforce, we will deliver on our goal of delivering safe, high-quality batteries with the lowest cost and carbon content. We are now in the process of accelerating and increasing our ambitions to scale up production for all relevant market segments.”

24M says it has reduced the number of steps required to manufacture battery cells, while still using conventional lithium-ion raw materials, decreasing capital expenditures and operational costs while increasing production throughput. The company claims its production platform is flexible, works across all chemistries and can be retooled for various sized batteries and cathode and anode chemistries.

FREYR says it’s experiencing strong interest for its battery cell production plans, and has announced several orders for battery cells in marine and stationary segments and for long-term supply of battery materials and production equipment.

Source: FREYR