Thermal runaway—the ignition or explosion of a battery cell caused by a self-reinforcing heating process—can be caused by a range of internal and external factors, such as overcharging, excessive discharging, damage, or heating of the battery. Thermal runaway releases not only flames and hot gases but also electrically conductive particles. These in turn can cause thermal propagation in adjacent cells and lead to short circuits.

Battery-makers are steadily increasing the energy density of their batteries, and Freudenberg Sealing Technologies tells us that this may actually increase the risk of thermal runaway. Freudenberg has developed thermal barriers that help to slow down thermal runaway by increasing resistance to propagation.

“What is completely new is that the thermal barriers are now also available in customized, flexible 3D geometries, which makes it possible to use them in various positions within the battery and allows for integration of additional components,” says Andrew Espinoza, Global VP Technology of the Oil Seals Powertrain & Driveline Division at Freudenberg.

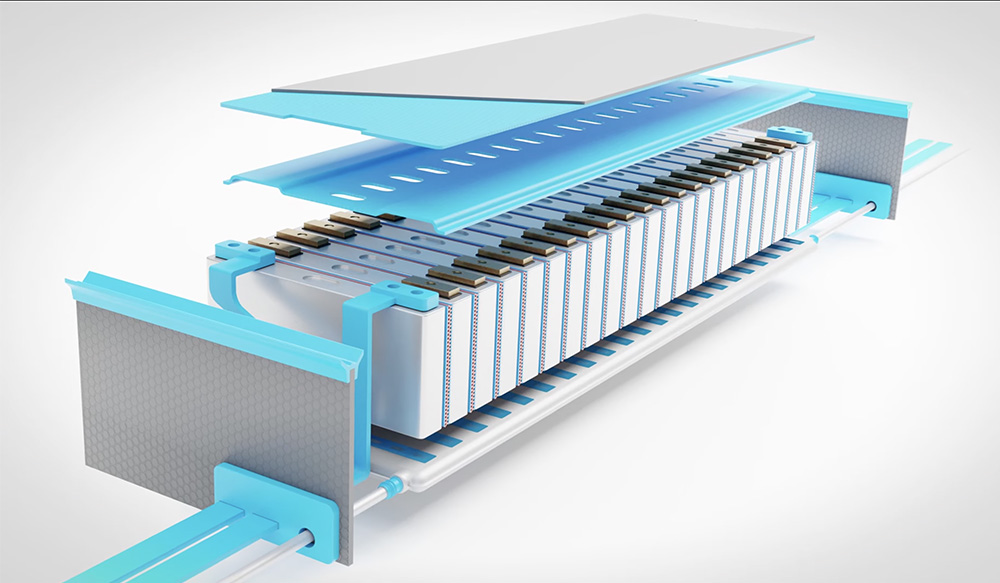

In addition to the existing two-dimensional barriers, such as flat mats and thermal blankets, customer-specific 3D geometries can be produced in a variety of high- and low-volume manufacturing processes, such as injection molding and continuous extrusion. Profile seals, module separators and covers—including those for bus bars, cooling lines or electrical components—are a few of the products currently being produced. Freudenberg says the complex 3D geometries are lightweight and have minimal impact on the battery’s overall weight.

“The three-dimensional thermal barriers and the utilized materials have gone through extensive testing that exceeds the required standards,” says Andrew Espinoza. “They have proven their outstanding performance and reliability on bench tests as well as battery system testing. The products meet the highest quality standards, are certified pursuant to UL 94 V-0 and are already being used successfully in initial series production for the automotive industry.”

Source: Freudenberg Sealing Technologies