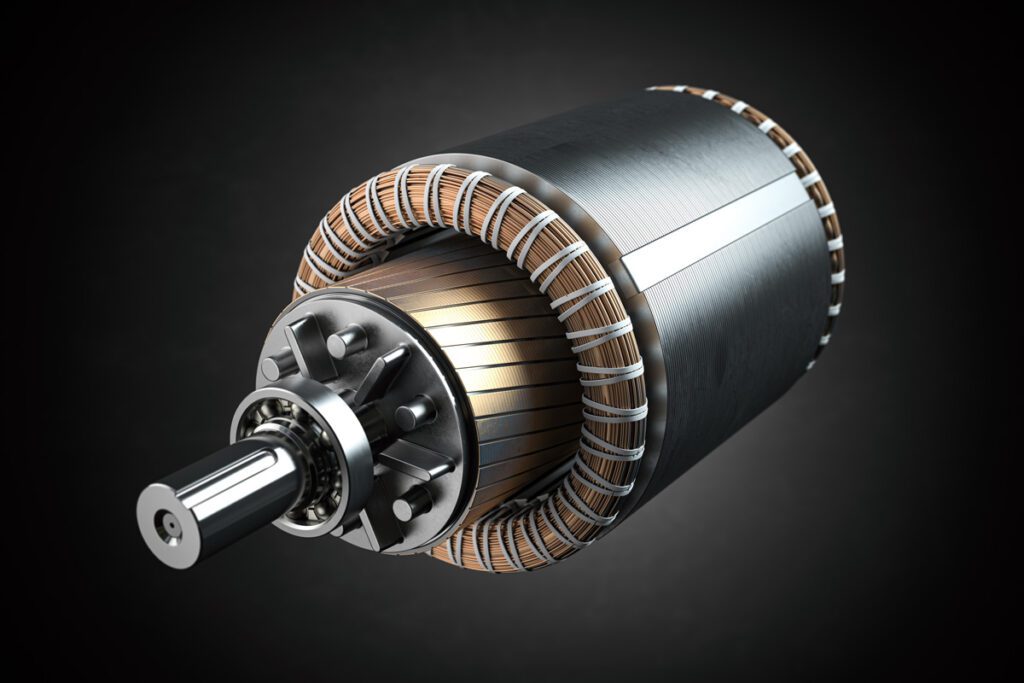

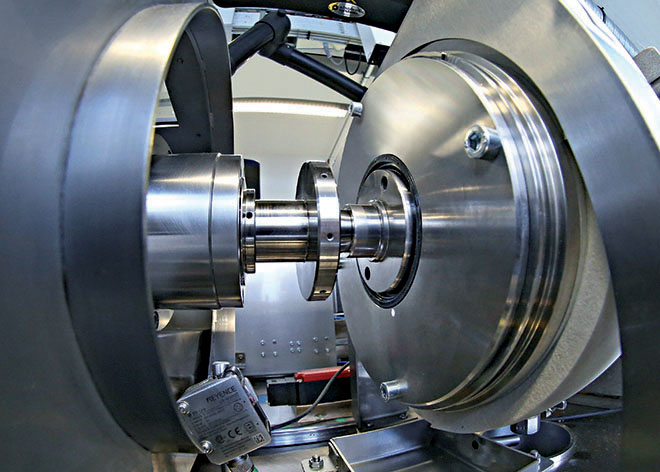

Freudenberg Sealing Technologies has introduced several specially-designed test stands to measure frictional torque in shaft seals used in electric motors. The stands, which are located in its Weinheim test facility, can measure at rotational speeds up to 36,000 rpm.

Freudenberg says that seals used between electric motors and downstream transmissions must withstand higher speeds and longer use than seals in conventional powertrains. While internal combustion engines in modern cars reach maximum rotational speeds between 4,000 and 7,000 rpm, electric motors for production EVs reach maximum rotational speeds of more than 20,000 rpm. Assuming future technical advances, Freunderberg estimates that rotational speeds could one day increase to 35,000 rpm.

Due to the high speeds, shaft seals used in electrified vehicles must produce very little friction. Otherwise, the efficiency of electric powertrains could suffer and cause premature wear.

Freudenberg has outfitted the test stands with several specific components to help ensure precise measurements. Torque is produced by water-cooled, high-rpm spindle drives. The test drum is equipped with nearly friction-free air bearings radially and axially so the seal’s frictional torque can be determined as precisely as possible.

The latest test stands, which are now in operation, can also capture each seal’s electrical impedance at a range of frequencies. Freudenberg says this measurement is important because electrical potential can be generated between the housing and the shaft of the electric motor, and discharge can take place across the shaft bearing and lead to surface damage from electrical erosion. Freudenberg already offers seals that enable the voltage to be drained off, and it hopes the new test stands will help to validate and aid in the design of these seals.

By correlating the measured frictional torque values with other values such as shaft diameter, Freudenberg intends to compare different sealing materials and designs at an early development stage. Since friction changes across the rotational speed, the company can then adapt the seals to later operating ranges before the first prototypes of the motors exist.

Grazyna Jedrowicz, head of testing at Freudenberg, said, “With the expansion of our test facility, we are gearing up for the new requirements that lie ahead for sealing technology due to electric mobility.”

Source: Freudenberg Sealing Technologies