The DOE’s Argonne National Laboratory has developed a new design that aims to improve the performance and reduce the costs of lithium-ion batteries.

Argonne researchers say the new “dual-gradient” design for the battery’s cathode increases energy storage capacity, stability and lifespan while reducing costs.

In 2012, Argonne researchers developed a novel nickel-manganese-cobalt cathode material to increase energy density and durability. The team recently began exploring ways to improve it further.

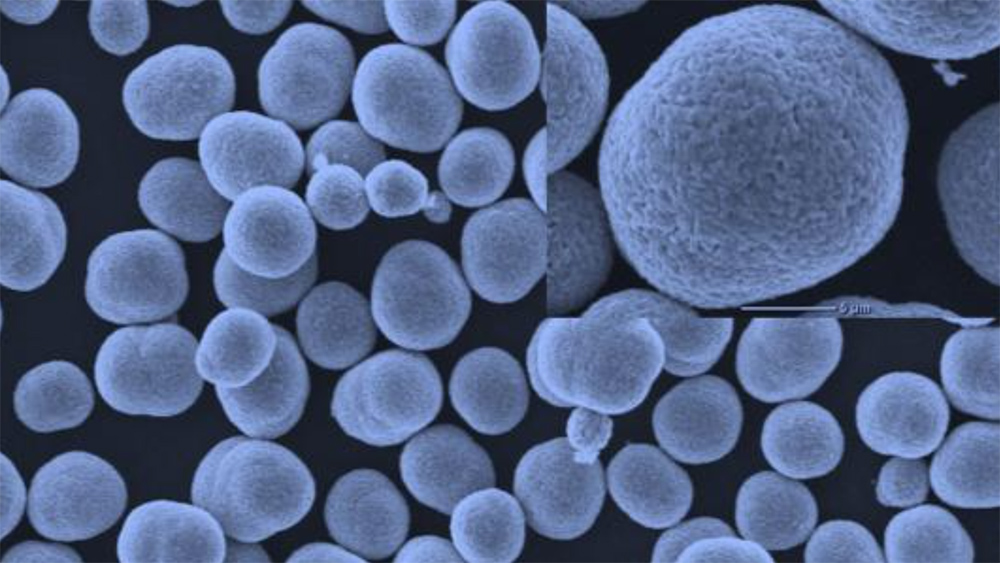

High-voltage operation tends to cause cathode particles with layered, ordered structures to crack and react more with the battery’s electrolyte, degrading the cathodes. The team’s solution was to fabricate cathode particles in which the structure gradually transitions from disordered material on the surface to ordered, layered material in the core. The surface is enriched in cobalt while the interior is nearly cobalt-free—less than 2% compared with 10-20% in the original design.

The disordered particle surface suppresses cracking and reactivity while the ordered core maximizes ion transport. In this way, the cathode can potentially achieve high capacity and stability while operating at high voltages.

The team performed a series of X-ray, electron and imaging experiments to characterize the new cathode material at rest and while operating. Together, these tests assessed the material at the cathode, particle and atomic levels. The tests confirmed that the particles remained structurally and chemically stable during high-voltage operation.

The dual-gradient particles were more durable than the original Argonne design, so that after charging and discharging the material 500 times, it lost only about 2% of its storage capacity. The team also found that the design enhanced the cathode’s ability to withstand heat, which is crucial to ensure safe operations at high voltage.

“This breakthrough material represents an across-the-board improvement for batteries,” said Amine. “It features higher storage capacity, robust stability and heat tolerance at high voltages, and longer lifetimes. Its high energy density enables production of smaller, lower-cost batteries, supporting widespread adoption of EVs and grid batteries. Our patented design and fabrication process is ready to be licensed by industry.”

Source: Argonne National Laboratory