Researchers at Germany’s Fraunhofer Institute have developed a modular battery system that could offer lower cost and improved range by making it easier to replace defective cells.

In theory, all the individual cells of a battery can store the same amount of energy. In practice however, their capacities vary, and because the cells are connected in series, the entire battery is only as strong as its weakest cell. For this reason, manufacturers pre-sort the cells, and install cells of similar capacity into a battery, a process that adds costs. Furthermore, a single defective cell can cause the entire battery to stop functioning.

Researchers at the Fraunhofer Institute for Manufacturing Engineering and Automation in Stuttgart have now created an alternative. “Our modular battery system solves these problems,” says Group Manager Dr. Kai Pfeiffer.

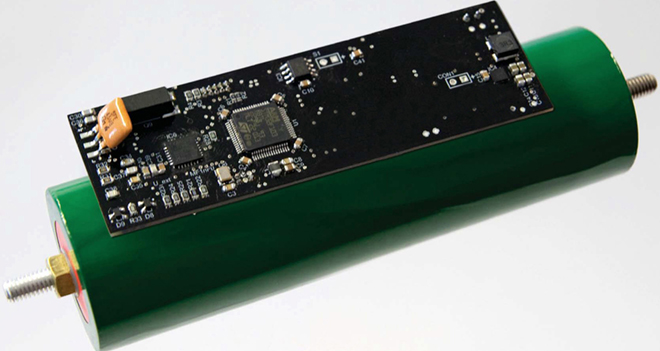

Each cell has its own built-in microcontroller that records physical parameters such as the temperature and the state of charge of the cell. The cells can exchange information with each other via the existing power wiring between cells. An on-board computer uses the data from the cells to calculate the current state of charge.

If a cell is empty, it simply decouples from the cluster, while the others continue to deliver energy. “Depending on the cell quality, we can therefore increase the range by at least four percent,” explains Pfeiffer. “Over time, this effect is amplified: in the case of an old battery, and if the empty cells are replaced, it is conceivable that a range up to ten percent higher can be achieved.”

The researchers have developed a prototype, and are now working to miniaturize the electronics and embed them into cells. “We want it to cost less than a euro,” Pfeiffer says.

Source: Fraunhofer Institute