FEV has developed a combined simulation and testing process for the optimization of thermal propagation behavior in automotive battery packs. The company claims the process can help to reduce the risk of injury and damage from battery cell thermal runaway, while also saving development time and cost.

Thermal runaway is a key safety aspect for hybrid and electric vehicles. The first thermal propagation regulation is expected in January 2021. The GB/T 38031 standard in China will require that vehicle passengers be warned at least five minutes before a fire from a thermal event extends beyond the battery pack, or battery venting gas enters the cabin. Other markets and regulatory bodies are expected to follow.

“FEV’s simulation-based approach to optimize for battery thermal propagation is paired with our design, development and testing capabilities at our world-class eDLP facility,” said CEO Stefan Pischinger. “This uniquely positions FEV to support the entire thermal propagation development process.”

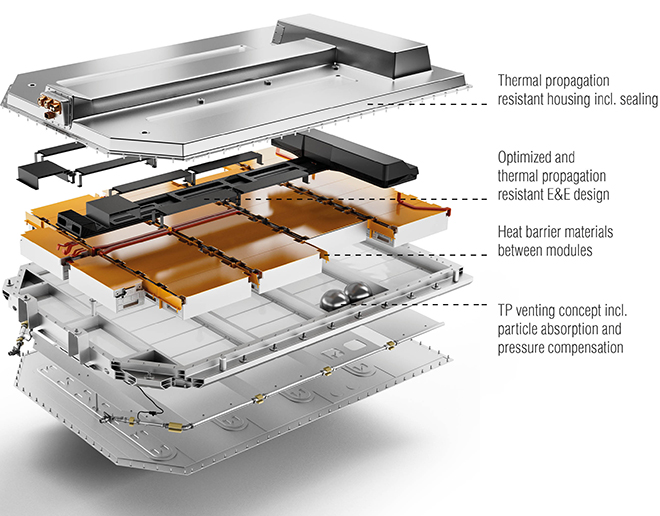

The simulation-based approach begins after key CAD dimensions and pack geometries are defined in the base development phase. FEV has created two customizable models for this purpose. Multiphysics simulation produces a model to evaluate and optimize thermal runaway of one cell and propagation between battery cells, as well as between battery modules. This model and its customization for specific customer requirements allow for design optimization and introduction of countermeasures such as heat barriers. In parallel, a second, fluid-based venting gas model is customized, which is used to assess and optimize the design of the venting paths, dimensioning of venting valves as well as the indication of critical busbar routing inside the battery pack.

The thermal and venting gas models are developed and then customized separately. Each model is validated further using physical test data. This testing approach is based on a step-by-step validation of cell to module to pack, whereas at the pack level, different dummy packs are used to evaluate thermal propagation behavior. The cascaded testing approach can be optimized if any data (e.g. cell data) are already available. Experimental data can be collected early in development, without building a fully functional battery pack.

After the models are validated with physical test data, they are combined into a comprehensive coupled model, containing the thermal battery model as well as local heat transfer coefficients and fluid/gas temperatures from the venting gas model. Finally, the design is tested and validated as a complete battery pack.

Source: FEV